Product Description

The micro-driven integrated electric gripper and the integrated rotary clamping electric servo gripper independently developed by Junduo for the field of in vitro diagnostics and laboratory automation equipment have been used in many testing automation equipment. It has high safety and is equipped with a mechanical self-locking mechanism. Its ultra-thin design can accommodate multiple workpieces placed side by side at a time.

Product parameters

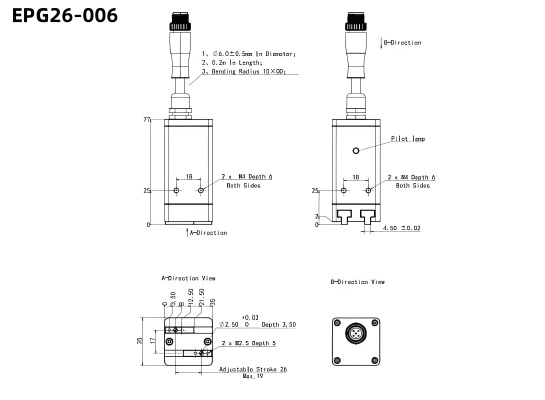

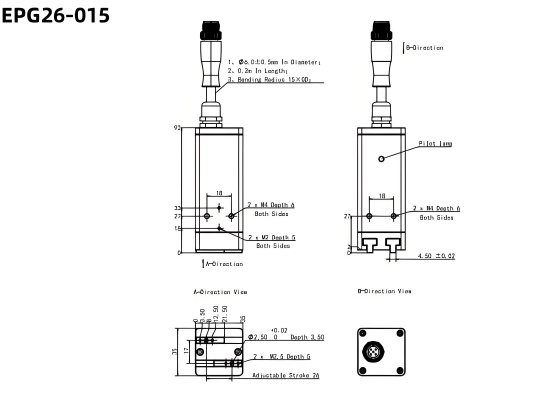

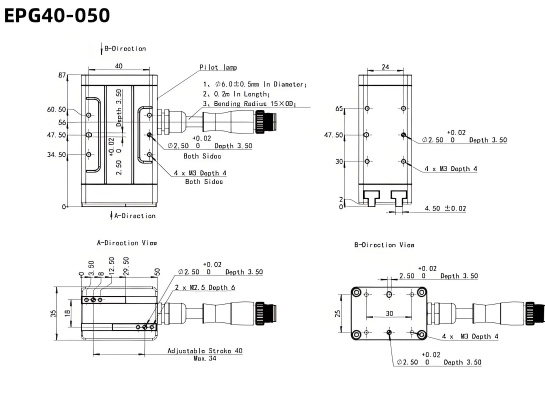

Model | EPG26-006 | EPG26-015 | EPG30-150 | EPG40-050 | EPG40-100 | EPG50-060 | EPG50-100 |

Adjustable stroke | 0-26mm | 0-26 mm | 0-30mm | 0-40mm | 0-40mm | 0-50mm | 0-50mm |

Single finger gripping force | 1-6N | 1-15N | 50-150N | 2-50N | 40-100N | 2-60N | 40-100N |

Opening/closing time | 0.25s | 0.3s | 0.3s | 0.5s | 0.9s | 0.6s | 1.10s |

Position repetition accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

*Maximum recommended load | 0.1kg | 0.3kg | 3Kg | 0.8kg | 2kg | 1kg | 2kg |

Drop detection | support | support | support | support | support | support | support |

Usage environment | 5-40 ℃, below 85% RH | 5-40 ℃, below 85% RH | 5~45 ℃, below 85% RH | 5-40 ℃, below 85% RH | 5-40 ℃, below 85% RH | 5-40 ℃, below 85% RH | 5-40 ℃, below 85% RH |

Running noise | <40dB | <40dB | <40dB | <40dB | <40dB | <40dB | <40dB |

Body weight | 0.20Kg | 0.25Kg | 0.9Kg | 0.36Kg | 0.37Kg | 0.57Kg | 0.53Kg |

IP level | IP40 | IP40 | IP40 | IP40、IP65 optional | IP40、IP65 optional | IP40、IP65 optional | IP40、IP65 optional |

Rated voltage | DC 24V±10% | DC 24V±10% | DC 24V±10% | DC 24V±10% | DC 24V±10% | DC 24V±10% | DC 24V±10% |

Maximum current | 0.85A | 0.85A | 0.85A | 0.85A | 0.85A | 0.85A | 0.6A |

Rated current | 0.4A | 0.4A | 0.4A | 0.4A | 0.4A | 0.4A | 0.25A |

communication protocol | Modbus RTU(RS 485) | Modbus RTU(RS 485) | Modbus RTU(RS 485) | Modbus RTU(RS 485),Digital I/O optional | Modbus RTU(RS 485),Digital I/O optional | Modbus RTU(RS 485),Digital I/O optional | Modbus RTU(RS 485),Digital I/O optional |

Compliant with international standards | CE、RoHS | CE、RoHS | CE、RoHS | CE、RoHS | CE、RoHS | CE、RoHS | CE、RoHS |

Vertical allowable static load Fz | 100N | 150N | 150N | 200N | 200N | 200N | 200N |

*Permissible static moment of slider Mx | 0.8N·m | 1.2N·m | 1.2N·m | 2N·m | 2N·m | 2N·m | 2.5N·m |

*The allowable static moment of the slider My | 0.6N·m | 0.9N·m | 0.9N·m | 1.5N·m | 1.5N·m | 1.5N·m | 2N·m |

*The allowable static moment Mz of the slider | 0.5N·m | 0.55N·m | 0.55N·m | 2N·m | 2N·m | 2N·m | 2.8N·m |

Product Display

Small size, high torque

Innovative design of core unit, reducing transfer and size

Optimizing transmission chain, reducing transmission links and improving efficiency

Optimizing transmission shortcomings and maximizing performance matching

High-precision force control

Use nonlinear control technology to optimize the mechanical model and get close to the actual Adaptive friction identification, based on the existing experimental friction model, add adaptive friction identification to improve the accuracy of the mechanical model

Use current/speed observer

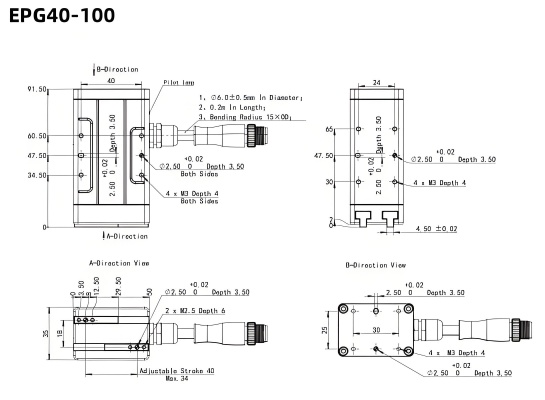

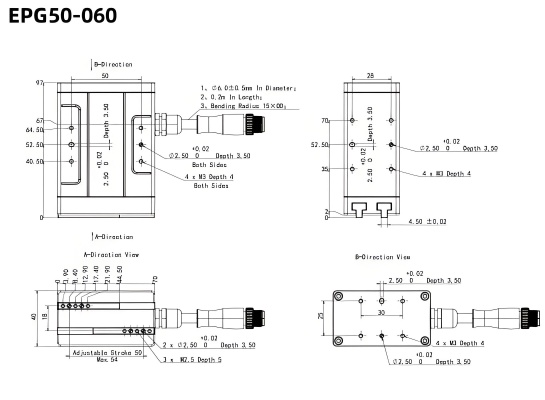

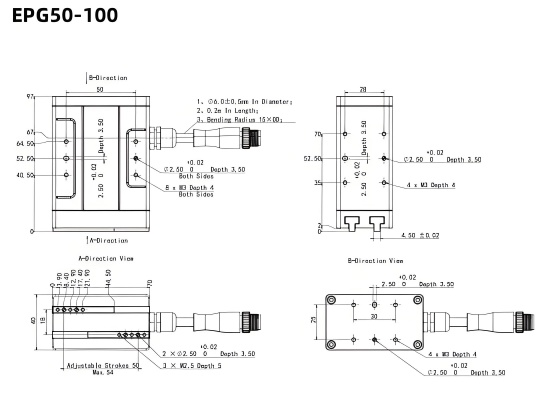

Size & Interface

Application Cases

The EPG40-050 electric parallel gripper is widely used. In the 3C electronics field, it can accurately grasp small parts and assist in the assembly of electronic products; in the production of medical devices, it can stably clamp delicate components to ensure product quality; in the automotive manufacturing process, it can carry medium-weight parts and improve production line efficiency. It is a powerful assistant for industrial automation.