Product Description

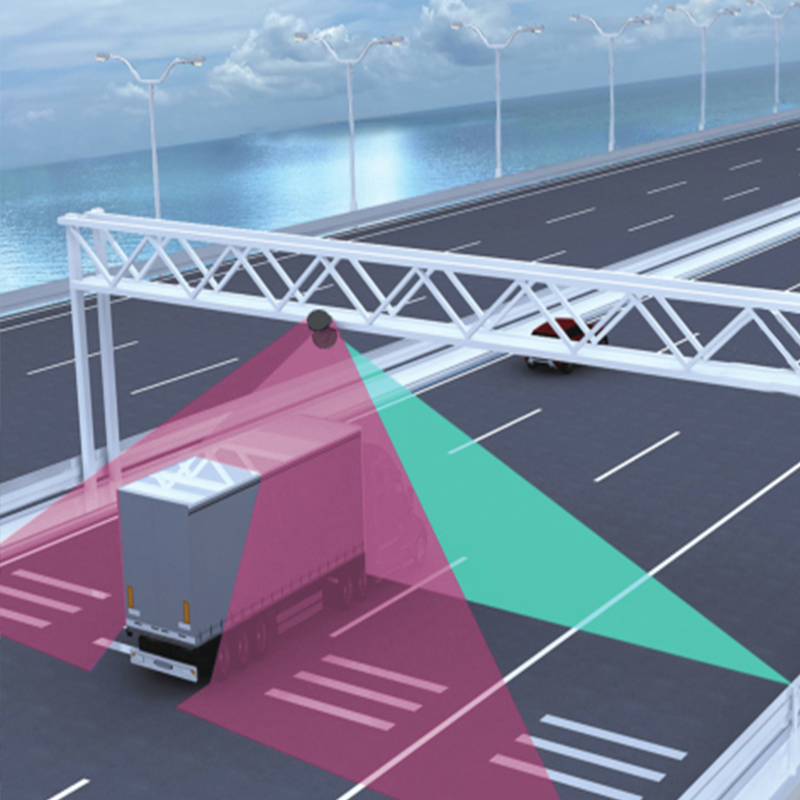

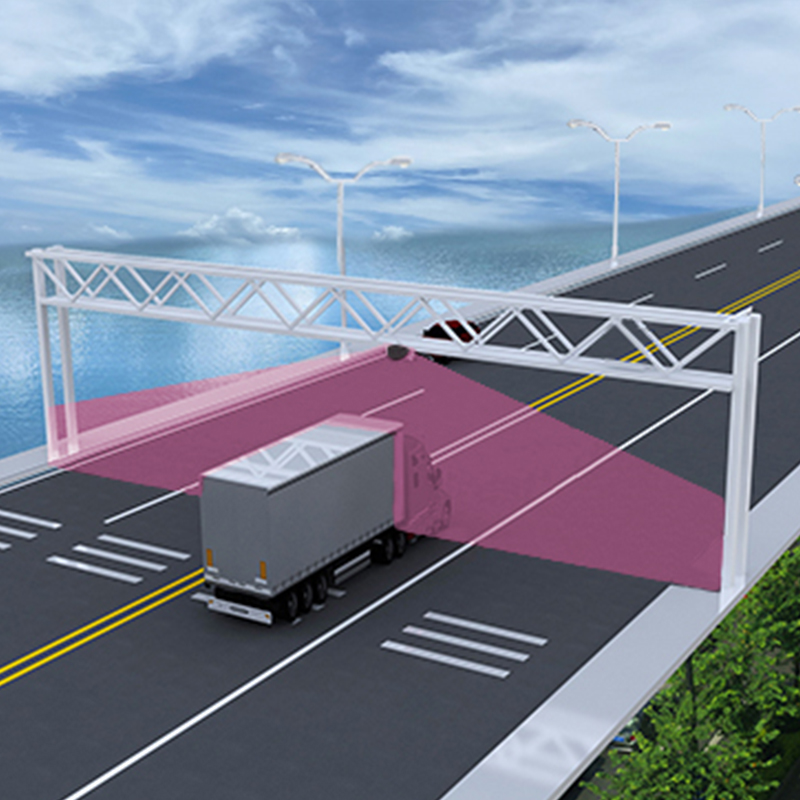

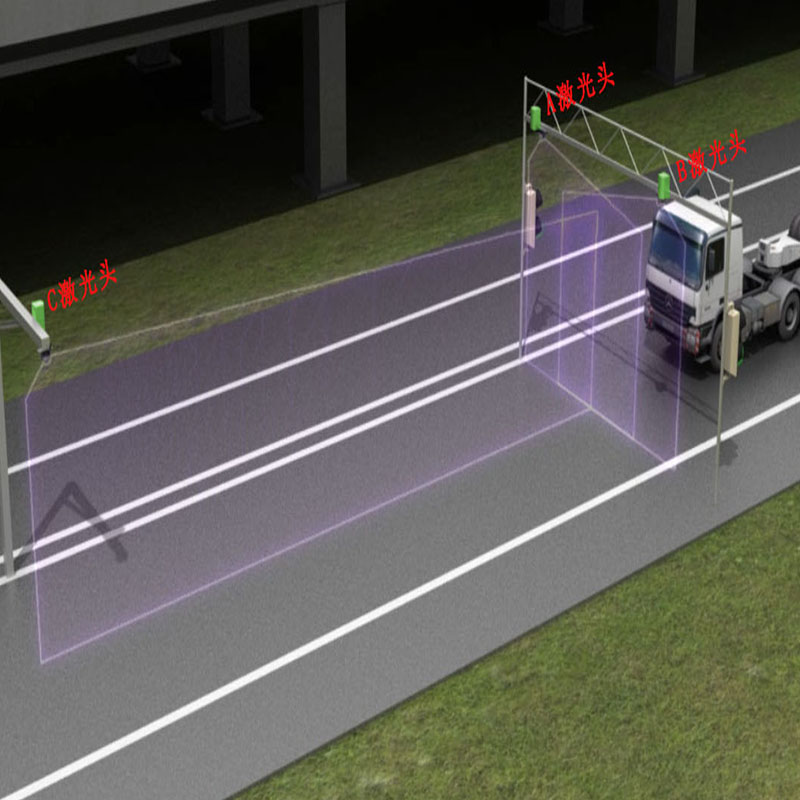

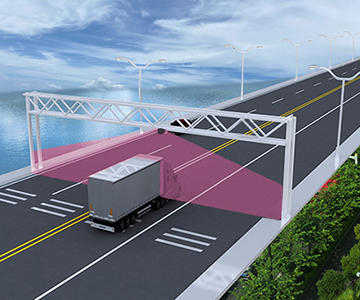

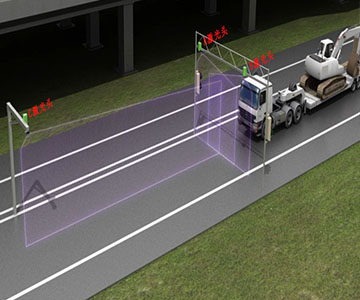

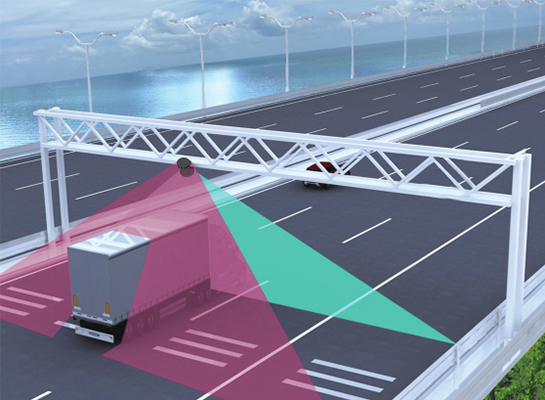

The multi-lane laser Traffic Flow Survey system (FS-ITS36) system is composed of 2 T lidar and data processing center, 2 T scanning Lidar top mounted in the center of the road, through two sections intersecting 45 degrees, the traffic flow information system is measured by 2 T Lidar and data processing center. Two T-scanning liDAR units are mounted in the middle of the road and measure traffic flow information through two sections intersecting 45 degrees.

Product parameters

| item | index |

|---|---|

| Model number | Multi-lane Laser Traffic Flow Survey System (FS-ITS36) |

| Single-class vehicle | ≥96% |

| Overall vehicle type | ≥97% |

| Flow data | ≥97% |

| Location speed data | ≥95% |

| Headway data | ≥95% |

| Headspace data | ≥95% |

| Output mode | TCP/IP |

| Detection laser source | 905nm invisible infrared light; Luminous power ≤1mW; |

| In line with the "Laser eye safety" (GB7247.1-2001) class I | |

| Projected laser light source | 650nm visible red light; Luminous power ≤5mW; |

| In line with the "Laser eye safety" (GB7247.1-2001) class III | |

| Ambient temperature and humidity | -40℃ -+ 50℃ below 85%RH |

| Store ambient temperature and humidity | -45℃ -+ 55℃ Below 85%RH |

| EMC specification | EN 61326-1:2013 EN 61326-2-3:2013 |

| Design service life | Use under standard conditions, 10 years |

| Housing material | Aluminium alloy |

Product Display

The output:

Motor vehicle traffic volume, headway, following percentage, headway, average headway, time occupancy.

Main uses:

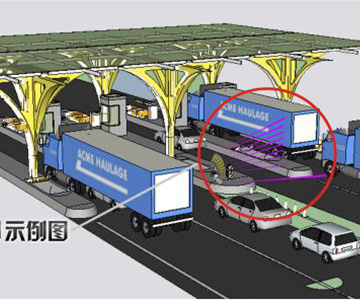

Bayonet multi-lane traffic flow survey.

China's fast laser measurement and control sensor leading enterprise - Shenzhen FaseLase laser radar (FaseLase) launched ITS laser intelligent transportation system to improve the previous intelligent transportation in the cross installation complex, difficult maintenance and other deficiencies, to achieve vehicle classification, vehicle detection and capture, vehicle speed detection, vehicle automatic classification, vehicle separation, Created a new milestone of ITS system.

Quality Control

- Optical component

For the laser in the laser emission module, the parameters such as wavelength accuracy and output power stability need to be strictly tested. For example, the deviation of the wavelength may affect the accurate reception and resolution of the light reflected by the liDAR on the target object, and the wavelength deviation is generally required to be controlled within a very small range, such as ±5nm.

The quality of the optical lens is also crucial. The curvature accuracy of the lens, the surface flatness and the transmittance of different wavelengths of laser light are all carefully tested. Any small flaw, such as a scratch or uneven curvature on the lens surface, can cause the laser to scatter or focus inaccurately, thus affecting the detection accuracy of the liDAR. The transmittance is generally required to reach more than 90% in a specific band.

- Electronic components

The chip on the circuit board is the "brain" of the lidar, and when conducting quality control, it is necessary to ensure that the performance of the chip meets the design requirements. For example, to test whether its data processing speed can meet the needs of liDAR to acquire and process large amounts of point cloud data in real time. At the same time, it is also necessary to check the stability of the chip in different temperature environments, because the lidar may generate heat during the working process, and the chip performance must be stable within a certain temperature range (such as -40 ℃ -85 ℃).

The parameter accuracy of capacitors, resistors and other discrete components can not be ignored. The deviation range between the nominal value and the actual value of these components should be controlled within a certain limit, such as the resistance value deviation of the resistance does not exceed ±1%, to ensure the normal operation of the circuit and the accuracy of signal transmission.

Application Cases

Shenzhen Fashi Lidar Co., LTD. (referred to as: Fashi Lidar) is a long-term engaged in rapid laser measurement and control technology research of pure technology enterprises, thousands of Lidar in the outdoor harsh environment, 365 days a year, 24 hours of long-term operation, failure rate of less than 1%, more than four years has been to provide customers with cost-effective products. The fast laser ranging sensor is used for the detection of fast moving objects and the detection of the surrounding environment of fast moving objects, and its speed, accuracy and detection distance can meet the needs of most customers. The main features of the product are fast measurement speed, small size, light weight, low power consumption and low cost. In addition, it can be measured by external timing control, which is convenient for ultra-dense installation, and is an application solution for fast-moving road vehicle detection, regional flow detection, train industry, high-speed rail, and port vessel obstacle avoidance. Such as: screen interaction, AGV, outdoor cleaning robot, forklift, industrial mobile robot, security door.

Service

- Product training services: The company can provide customers with training on the use of Lidar products, operational processes, data interpretation and other aspects. This helps customers make better use of LiDAR equipment and reduce problems caused by improper operation. For example, engineers in automotive manufacturing companies are trained in the commissioning and data collection methods of in-vehicle lidar so that they can understand how radar works in autonomous driving scenarios.

- Product customization services: According to the special needs of different customers, the performance parameters of Lidar (such as detection distance, angular resolution, scanning frequency, etc.), dimensions, installation methods, etc., are customized. For example, for space-constrained UAV application scenarios, customized miniaturized and lightweight liDAR.