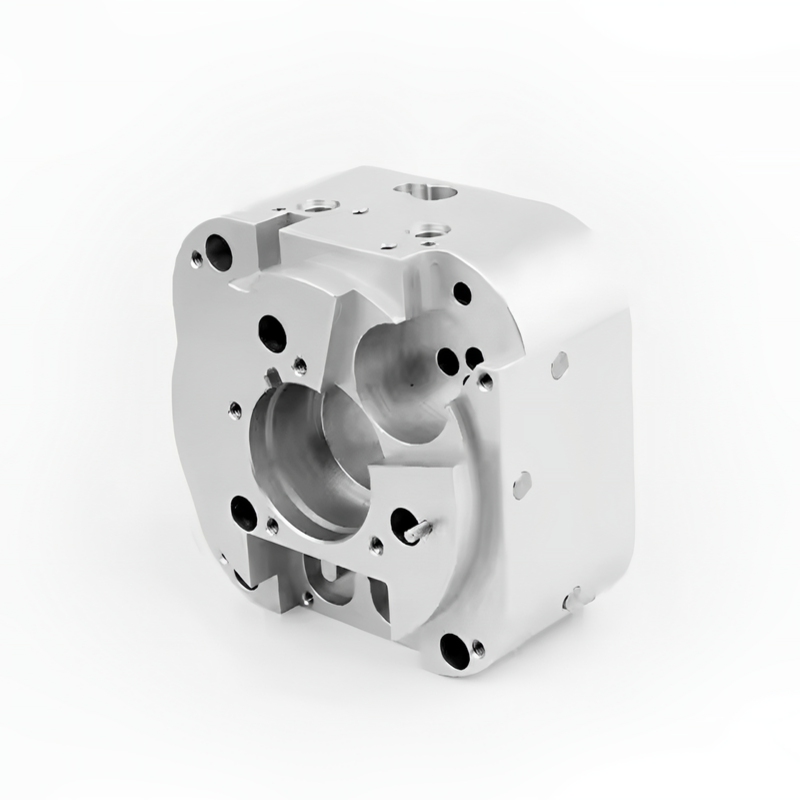

Product Description

The cutter head is engineered for precision cutting, providing exceptional durability and high performance in a wide range of machining applications. Designed to deliver smooth, accurate results, it ensures efficient material removal while maintaining long-lasting reliability, making it the ideal choice for complex and demanding projects. Suitable for various materials, it enhances cutting efficiency and quality.

Product parameters

| ITEM NO | ΦD(mm) | W(mm) | Φd(mm) | Z | Knives(pcs) |

|---|---|---|---|---|---|

| ST615 100060 | 100 | 60 | 30/35/40 | 6 | 15 |

| ST615 100080 | 100 | 80 | 30/35/40 | 6 | 18 |

| ST615 100100 | 100 | 100 | 30/35/40 | 6 | 24 |

| ST615 100130 | 100 | 130 | 30/35/40 | 6 | 30 |

| ST615 100140 | 100 | 140 | 30/35/40 | 6 | 33 |

| ST615 100150 | 100 | 150 | 30/35/40 | 6 | 36 |

| ST615 100180 | 100 | 180 | 30/35/40 | 6 | 42 |

| ST615 125060 | 125 | 60 | 40/50 | 6 | 15 |

| ST615 125080 | 125 | 80 | 40/50 | 6 | 18 |

| ST615 125100 | 125 | 100 | 40/50 | 6 | 24 |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Wood Cutting Machines

Used in the woodworking industry to cut and shape wood for furniture and other products.

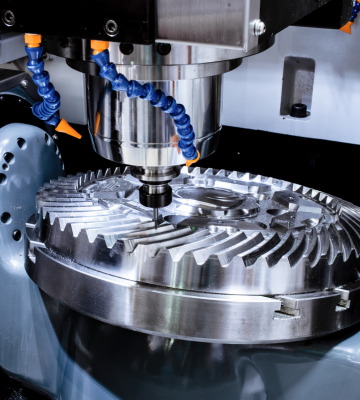

CNC Milling Machines

Used for precise cutting and shaping of materials like metal and plastic.

Lathes

For turning and cutting cylindrical or round-shaped parts.

Material

Aluminum Alloy

Brass

Stainless Steel

Copper

Quality Control

Quality control for the LIVTER 125*60*40mm cutter head includes checking material quality, verifying dimensions, inspecting for surface defects, and testing hardness. The cutter head is balanced to prevent vibrations, and performance is tested for efficiency and durability under various conditions. Proper packaging ensures protection during shipping.

Processing capability

The processing capability of the LIVTER125*60*40mm cutter head allows for precise and efficient cutting of various materials, including metals, plastics, and composites. It can handle a wide range of machining applications, providing smooth, accurate results with high durability. The cutter head is designed to maintain performance under high-speed conditions, making it suitable for both light and heavy-duty tasks. Its high hardness ensures it can withstand wear and maintain sharpness, offering consistent results over time. The cutter head can be used in CNC milling machines, lathes, and other industrial machinery, ensuring versatility in different manufacturing environments.

Additional processes

The LIVTER LIVTER125*60*40mm cutter head may undergo several additional processes to enhance its performance and longevity. Surface coating is applied to improve wear resistance and protect the cutter head from corrosion. Heat treatment is used to increase hardness, making it more durable and able to withstand high-stress machining tasks. Polishing is performed to improve surface smoothness, reducing friction and ensuring cleaner cuts. Additionally, balancing is done to eliminate vibrations during operation, ensuring stability and precision. These processes collectively enhance the cutter head’s ability to deliver consistent, high-quality results across various machining applications.