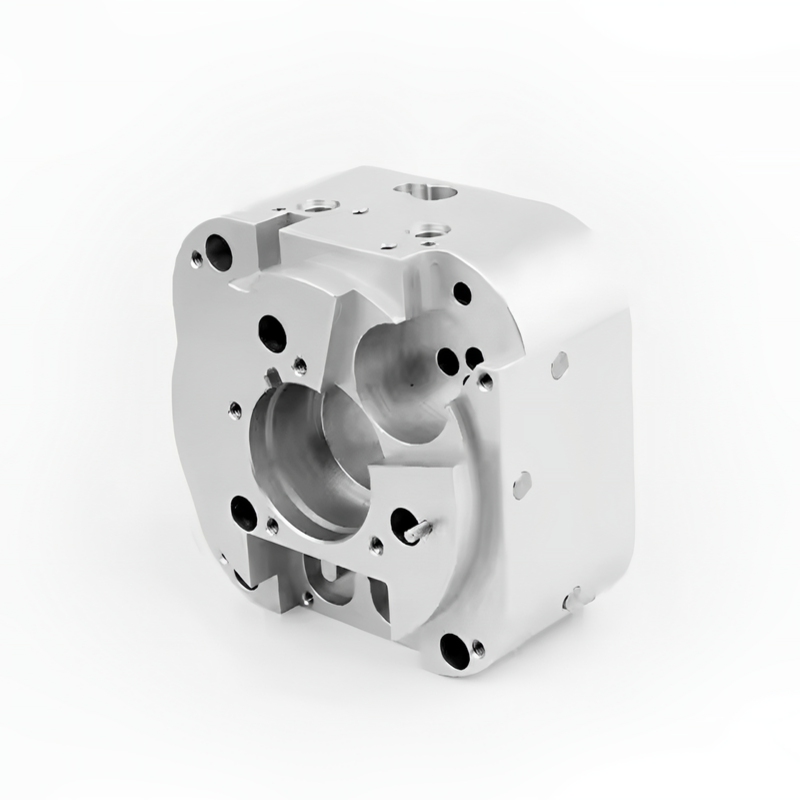

Product Description

The Precision 5-Axis Impeller is a high-performance component designed for advanced machining. It enables the creation of complex geometries with exceptional accuracy, ensuring optimal cutting angles and efficient machining. Made from durable, high-quality materials, it withstands high-stress applications, making it ideal for industries like aerospace, automotive, and energy, where performance and reliability are crucial

Product parameters

| Item name | CNC machining |

| Tolerance | minimum tolerance 0.0002mm |

| Material | Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. Copper: C11000,C12000,C12000, C36000 etc. Plastic: ABS, PC, PE, POM, Delrin, Nylon, PP, Peek etc. Other: Titanium,etc.We handle many other type of materials. Please contact us if your required material is not listed above. |

| Surface Treatment | Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black,Electrophoresis black Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing. Brass: Nickel plating,chrome plating,Electrophoresis black,Oxide black,Powder coated. Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Testing Machine | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, projecter machine, roughness tester, hardness tester and so on |

| MOQ | 1 piece |

| Delivery time | 10-15 days after placed order |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

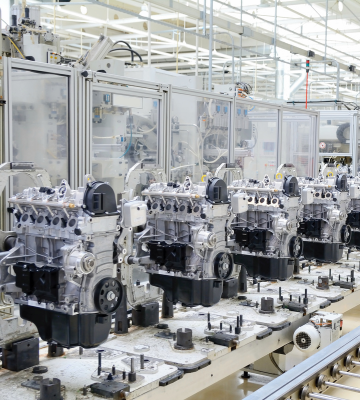

Automotive Manufacturing Machines

Used for producing complex parts like engine components or parts that require high precision in assembly. The Precision 5-Axis Impeller allows for multi-angle cutting, improving accuracy and reducing errors in the production of detailed parts.

Aerospace Manufacturing Machines

Used for manufacturing aircraft components, such as turbine blades, which must endure high temperatures and pressures. The Precision 5-Axis Impeller ensures precise cutting and durability, even under extreme conditions.

Wind Turbine Manufacturing Machines

Used to produce blades for wind turbines that require precise design and cutting to reduce friction and improve rotational efficiency. The Precision 5-Axis Impeller ensures durable and long-lasting blades that can withstand high wind forces

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

The quality control of the Precision 5-Axis Impeller includes verifying material quality, ensuring dimensional accuracy, and inspecting the surface for defects. The impeller is balanced to eliminate vibrations, undergoes hardness testing for durability, and is performance-tested under various conditions. It is carefully packaged to prevent damage during shipping

Processing capability

The Precision 5-Axis Impeller is capable of producing highly intricate and complex geometries with exceptional precision. Its 5-axis machining allows for optimal cutting angles and tool paths, ensuring high efficiency in material removal. The impeller can handle various materials, including metals and composites, and is designed to maintain excellent performance even under high-speed, high-stress conditions. This capability makes it suitable for demanding applications where precision and durability are critical, such as in aerospace, automotive, and energy industries.

Additional processes

The Precision 5-Axis Impeller undergoes several additional processes to enhance its performance and longevity. These include surface coating to improve wear resistance and protect against corrosion, heat treatment to increase hardness and durability, and polishing to reduce friction and improve surface smoothness. Balancing is also performed to eliminate vibrations during operation, ensuring stability and precision. These processes work together to ensure that the impeller performs reliably under demanding conditions