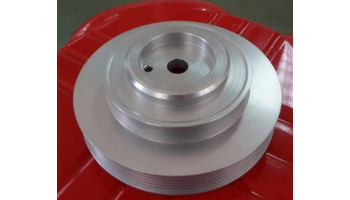

Product Description

We specialize in crafting high-precision machined products, utilizing cutting-edge manufacturing techniques and state-of-the-art equipment to deliver exceptional accuracy and reliability. Our experienced team is committed to designing and producing custom-engineered components tailored to meet the unique requirements of each customer. Whether for automotive, aerospace, or industrial applications, we ensure consistent quality and outstanding performance in every product we create.

Product parameters

| Material | Aluminum (6061-T6, 6063, 7075-T6,5052) etc... Brass/Copper/Bronze etc... Stainless Steel (302, 303, 304, 316, 420) etc... Steel (mild steel, Q235, 20#, 45#) etc... Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

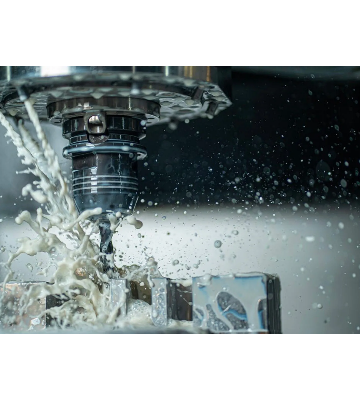

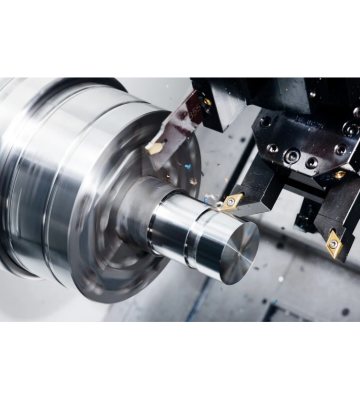

| Process | CNC Machining, CNC turning, CNC milling, CNC lathe machining, CNC boring, CNC grinding, CNC drilling etc... |

| Surface treatment | Clear/color anodized; Hard anodized; Powder-coating; Sand-blasting; Painting; Nickel plating; Chrome plating; Zinc plating; Silver/gold plating; Black oxide coating, Polishing etc... |

| Gerenal Tolerance (+/-mm) | CNC Machining: 0.005 Turning: 0.005 Grinding(Flatness/in2): 0.003 ID/OD Grinding: 0.002 Wire-Cutting: 0.002 |

| Certification | ISO9001:2008, ROHS |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 20 years of CNC machining products 3 years of automation machine manufacturing |

| Packaging | Standard: pearl cotton and bubble bag, carton box and seal For large and big quantity: pallet or as per customers' requirement |

| Lead time | In general:7-15days |

| Term of Payment | T/T, Paypal, Trade Assurance etc... |

| Minimum Order | Comply with customer's demand |

Custom Process

1. Product Design

2. CNC Turning / Milling

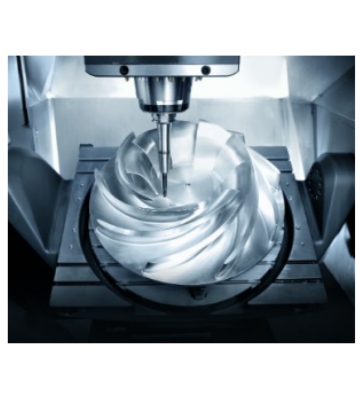

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Process Type

CNC Machining

Lathing

Gear detection

CNC Milling Processing

Turning

Five-axis Machining

Material

Aluminu Alloy

Stainless Steel

Aluminum-Alloy Block

Brass

Copper

Tube Material

Special Steel

Contact Us

Additional processes

Abrasive Jet Machining (AJM)

· Applications: Commonly used for cleaning hard-to-reach areas, deburring sharp edges, or cutting fragile or soft materials like plastics or ceramics.

Key Benefits: Capable of producing fine finishes, good for fragile materials, and can be used for very intricate parts.

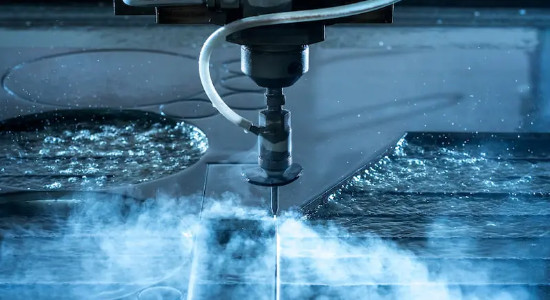

Water Jet Cutting

· Applications: Used in industries where heat-sensitive materials are involved, such as aerospace, automotive, and stone cutting.

Key Benefits: Can cut through a wide range of materials, no thermal distortion, and suitable for intricate shapes.

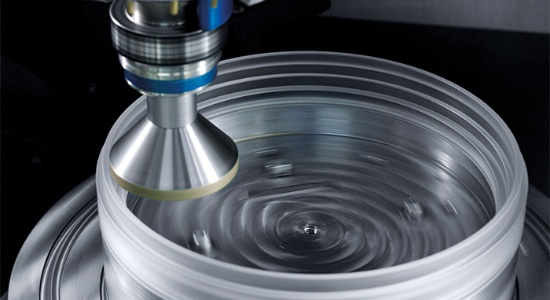

Ultrasonic Machining (USM)

· Applications: Commonly used for machining brittle materials like ceramics, glass, and hard metals.

· Key Benefits: Produces no heat, excellent for brittle materials, and allows for fine detail machining with minimal tool wear.