Product Description

LCZ-202L column sensor has compact structure, high comprehensive accuracy, good long-term stability, high dynamic response frequency, and nickel-plated surface of high-quality alloy steel. It is widely used in large force testing machines, standard force gauges, pressure testing instruments, automation equipment and testing fields.

Product parameters

| Parameters | Technical Parameters | Parameters | Technical parameters |

|---|---|---|---|

| Range | 0~1000T | Material | Alloy steel |

| Output sensitivity | 2.0/3.0±10%mV/V | Impedance | 700Ω |

| Zero output | ±2%F.S. | Insulation resistance | ≥5000MΩ/100VDC |

| Non-linearity | 0.3%F.S. | Use voltage | 5~15V |

| Hysteresis | 0.1%F.S. | Operating temperature range | -20~80℃ |

| Repeatability | 0.1%F.S. | Safe overload | 150%F·S |

| Creep (30 minutes) | 0.05%F.S. | Extreme overload | 200% |

| Temperature sensitivity drift | 0.05%F.S./10℃ | Cable specifications | Φ5x3m |

| Zero temperature drift | 0.05%F.S./10℃ | Cable ultimate tension | 10kg |

| Response frequency | 10kHz |

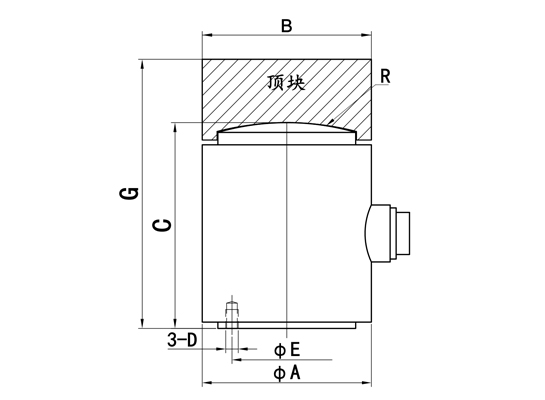

| Range | ΦA | ΦB | ΦC | D | E | R | G |

| 30~50T | Φ78 | Φ78 | Φ100 | M6 | 55 | 100 | 125 |

| 60~100T | Φ98 | Φ98 | Φ110 | M6 | 75 | 120 | 140 |

| 200T | Φ128 | Φ128 | Φ140 | M6 | 100 | 200 | 180 |

| 300T | Φ154 | Φ154 | Φ170 | M8 | 120 | 300 | 215 |

| 500T | Φ196 | Φ196 | Φ220 | M10 | 150 | 400 | 275 |

| 700~1000T | Φ246 | Φ246 | Φ282 | M16 | 190 | 500 | 352 |

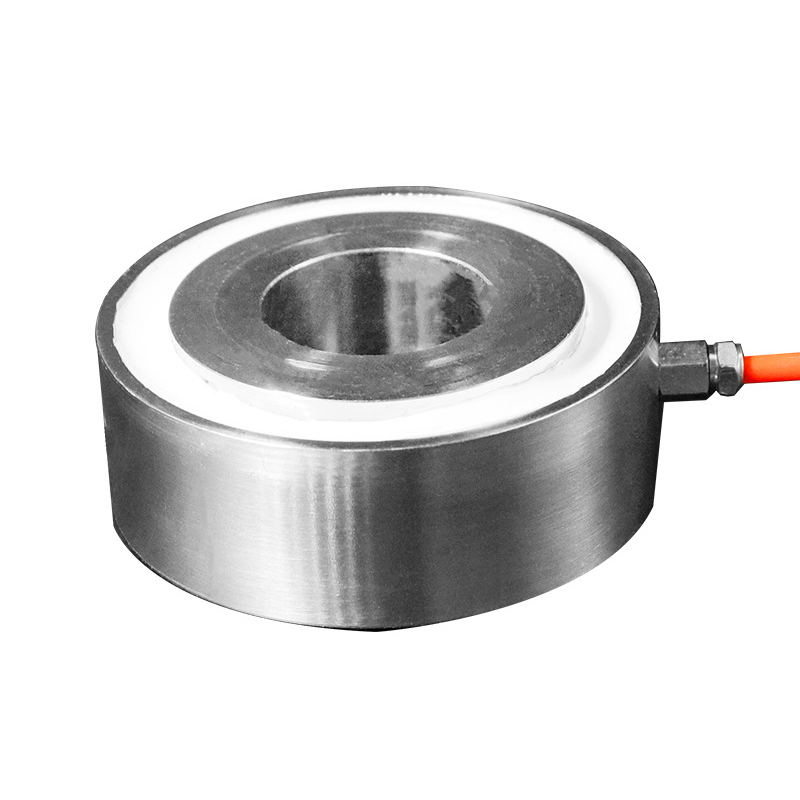

Product Display

- High precision and stable performance

High sensitivity and stable performance. Widely used in large force testing machines, standard dynamometer pressure testing instruments

- Using columnar beam structure

Compact structure, high comprehensive precision, good long-term stability, high dynamic response frequency, high-quality stainless steel material

- Good structural sealing

It has a large measuring range, good structural sealing, stable and reliable performance, easy installation and use, and is nickel-plated on the surface of high-quality alloy steel.

- High dynamic response frequency

It can respond quickly and timely to changes in the measured object. In the measurement scenarios of rapidly changing physical quantities, such as vibration monitoring of high-speed mechanical parts and measurement of fast-flowing fluid parameters, it can quickly capture changes and provide timely feedback of corresponding data to ensure the real-time and effectiveness of the measurement, providing strong support for the precise control and analysis of dynamic processes.

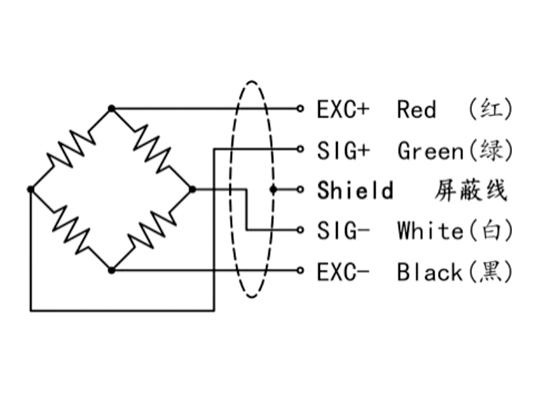

Size & Interface

Quality Control

Sensor quality control is extremely important. During the production process, strict control is required from the purchase of raw materials to ensure their high quality. Each process must be accurately monitored and tested, and no details that may affect the quality must be missed. After the finished product is completed, it must pass a variety of rigorous tests, including performance tests, environmental adaptability tests, etc., to ensure that the sensor can work stably and accurately under different conditions and meet the needs of various application fields such as industry, medical care, and automobiles.

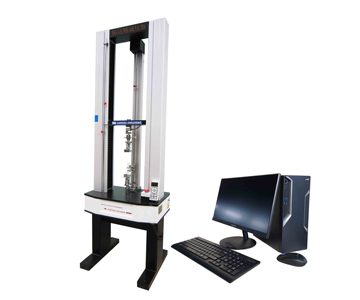

Application Cases

LCZ-202L column sensor has a wide range of applications in many fields. It is widely used in professional equipment such as large force testing machines, standard force gauges, pressure testing instruments, etc., providing strong support for the precise measurement of these equipment. At the same time, it also plays an indispensable role in the field of automation equipment and various testing fields. It is one of the key components to ensure the normal operation and precise measurement of these fields.

Service

1. Longlv provides customers with remote installation and debugging services, as well as other technical consultations. When necessary, technicians can provide on-site technical training. If customers have any technical questions, technicians will respond within 24 hours.

2. Longlv products are strictly designed and produced in accordance with the ISO9001 international quality system. Sensor products have a 1-year warranty. Instrument products have a 3-year warranty, 7-day return and exchange, and lifetime maintenance. (Man-made damage is not covered by the warranty, and customized products are not returned or exchanged without quality problems.)

3. For returns and exchanges due to quality problems, Longlv will bear the return and exchange freight. For returns and exchanges not due to quality problems, the customer will bear the cost. Note: Quality problems refer to customized parameters such as functions, dimensions, indicators, and installation methods that are not customized according to the customer's requirements, inconsistent functions, dimensional errors, and inaccurate precision (except within the error range). Customized products must be processed and produced after both parties confirm the drawings. If the product does not meet the customer's requirements, a written objection must be raised within two weeks. If the customer does not raise an objection within the prescribed period, it will be deemed to have passed the acceptance. If an objection is raised within the time limit, both parties confirm that it is indeed a product quality problem or it is not produced according to the requirements confirmed by both parties, it can be exchanged or refunded. If there is no quality problem, and the delivery model is complete and correct with the contract model, no return and exchange service will be provided.

4. The test results of products returned to the factory for repair will be issued within 3 working days, and the repair will be completed within 7 working days.