Product Description

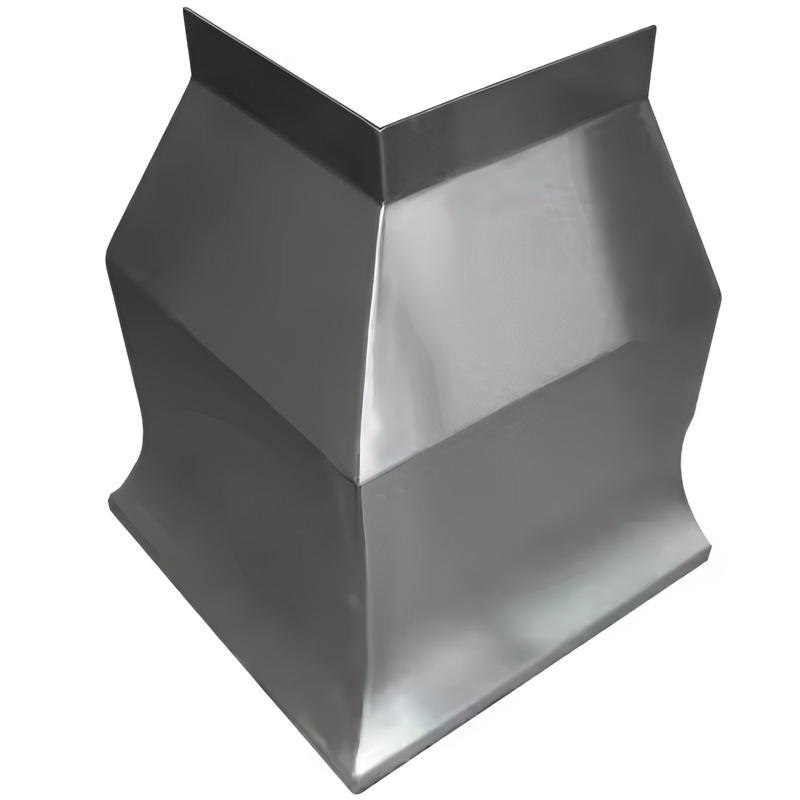

Sheet metal products are highly durable and versatile, making them ideal for a wide range of structural and industrial applications. Their ability to be easily shaped and customized allows them to support diverse industries, including machinery manufacturing, electronics, automotive, and construction, offering efficiency and reliability in every use.

Product parameters

| Material | Aluminum, stainless steel, copper, brass, galvinized etc. |

| Size | Customized |

| Tolerance | Average level: ±0.05mm, depending on product's size, thickness and material |

| Surface treatment | Powder coating, electroplating, oxide,anodizatio |

| Technics | laser cut, bend, weld, stamp |

| OEM | Accept |

| Drawing Format | 3D/CAD/Dwg/IGS |

| Color | Customized |

| Application | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Metal Lockers and Furniture

commercial and industrial environments, sheet metal is ideal for creating secure, durable lockers and heavy-duty furniture. It can withstand wear and tear from daily use while providing a high level of security, making it a popular choice for schools, gyms, and workplaces.

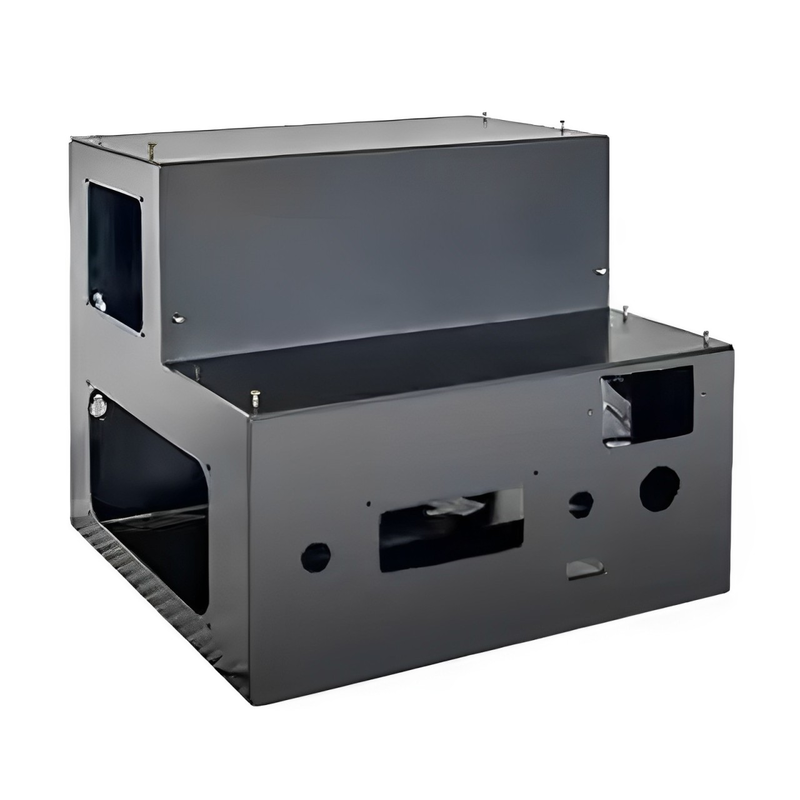

Computers and Servers

Sheet metal is used in the construction of computer cases, server racks, and cooling systems. Its excellent heat dissipation properties help regulate temperature, protecting sensitive electronic components. Additionally, sheet metal offers strong structural support to safeguard delicate internal parts during handling or operatio

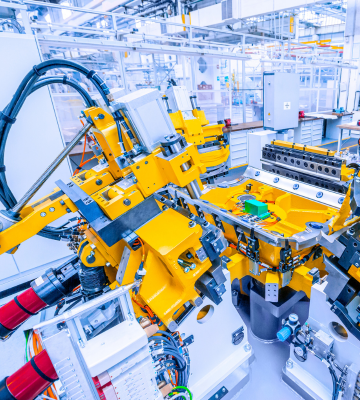

Industrial Machinery

Sheet metal is a critical material in the construction of industrial machinery, including components such as housings, panels, and structural supports. Its strength and ability to be precisely cut, bent, and welded allow manufacturers to produce robust machinery capable of handling heavy loads and extreme conditions

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality Control for sheet metal products ensures accuracy, strength, and adherence to standards to meet customer requirements. Key processes include thickness and dimension checks, surface inspections for coatings and corrosion, strength and durability tests, and precision assessments of bending and welding. These steps guarantee high-quality products suitable for diverse industrial applications

Processing capability

The processing capability of sheet metal products encompasses precise cutting, bending, stamping, and welding, enabling the creation of complex and customized components. These capabilities allow for the efficient production of high-quality, durable parts that meet specific industry requirements. This versatility makes sheet metal suitable for applications in sectors such as automotive, electronics, and construction, where strength, accuracy, and adaptability are essential

Additional processes

Additional processes for sheet metal products include finishing techniques such as coating, painting, and anodizing, which enhance durability, corrosion resistance, and appearance. Other processes, like embossing and perforating, add functionality and aesthetic appeal, making sheet metal components versatile for specialized uses across industries