Product Description

Harmonic reducer is a new type of reduction device, mainly composed of three basic components: wave generator, flexible gear (flexwheel), and rigid gear (rigid wheel). Harmonic reducer is widely used in industrial robots, CNC machine tools, aerospace, medical equipment, automated production lines and other fields. In the field of robotics, it can achieve high-precision position control to ensure that the robot's end effector can accurately reach the predetermined position and perform delicate operations, such as assembling tiny parts and welding electronic products. Although it is small in size, it can provide a large torque in a limited space to meet the power requirements of the robot in situations such as carrying heavy objects and performing complex processing tasks.

Product parameters

| Reduction ratio | 30 | 50 | 80 |

| Input rated torque at 2000r/min | 0.25Nm | 0.4Nm | 0.52Nm |

| Allowable peak torque at start and stop | 0.5Nm | 0.9Nm | 1.35Nm |

| The max. allowable torque of the average load | 0.38Nm | 0.53Nm | 0.84Nm |

| Instantaneous maximum allowable torque | 0.9Nm | 1.8Nm | 2.5Nm |

| Backlash | ≤20Arcsec | ≤20Arcsec | ≤10Arcsec |

| Maximum input speed allowed | 10000rpm | ||

| Allowable average inputspeed | 6500rpm | ||

Technological Features

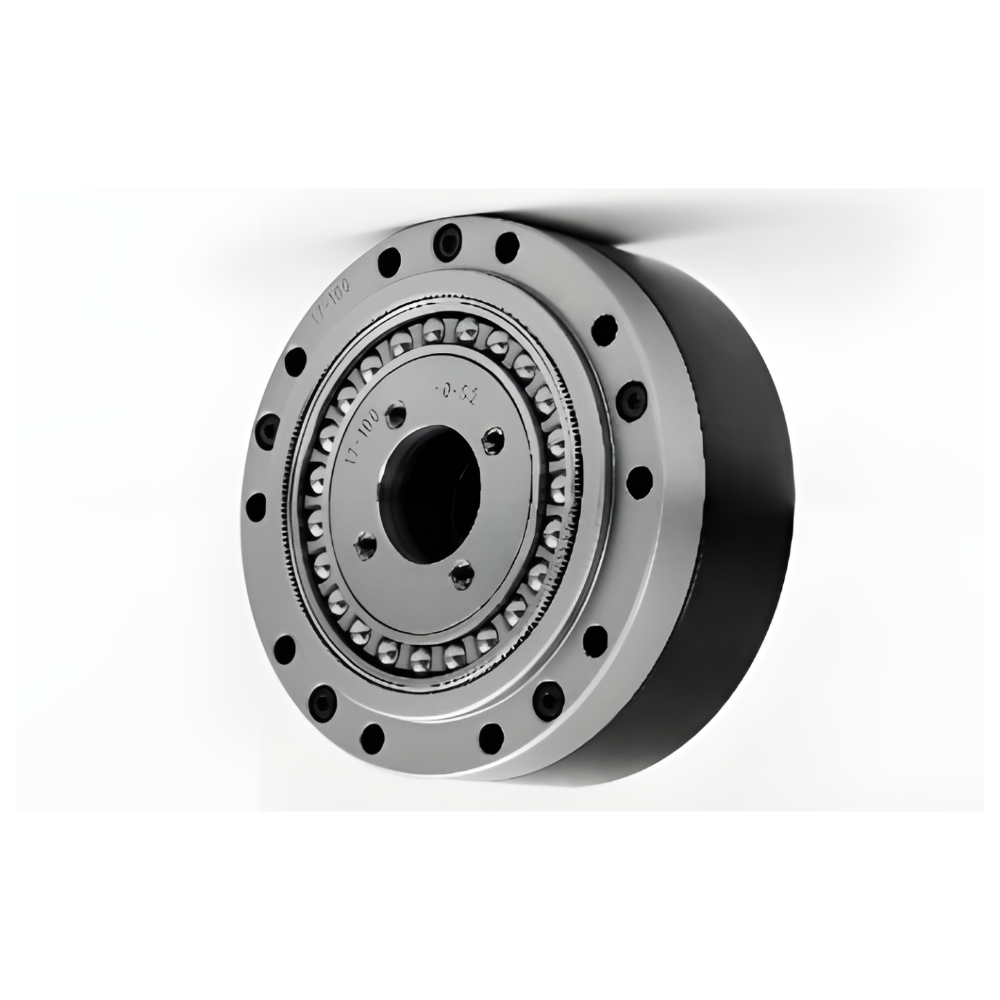

Ultra-micro cross roller bearings

The production of micro cross roller bearings is different from conventional models. The embedded separated groove structure designed by us perfectly avoids the lack of ultra-small raceway grinders in the market. Through structural design, the problem of ultra-small processing of raceway grinders is solved from the technical level.

Ultra-micro flexible bearings

The manufacturing process of micro flexible bearings cannot follow the conventional bearing processing process of separate processes to reduce the problem of multiple clamping size chain errors and deformation due to their small outer diameter and thinness. Instead, a composite processing method is required in which the finished product is produced at one time. We have joined forces with the technical team of a well-known domestic bearing research institute to add the functions of raceway grinding and laser heat treatment on the basis of a small precision composite machining center, realizing a one-time completion process from turning-heat treatment-grinding ultra-precision raceway, which has efficiently solved the manufacturing problem of ultra-micro flexible bearings.

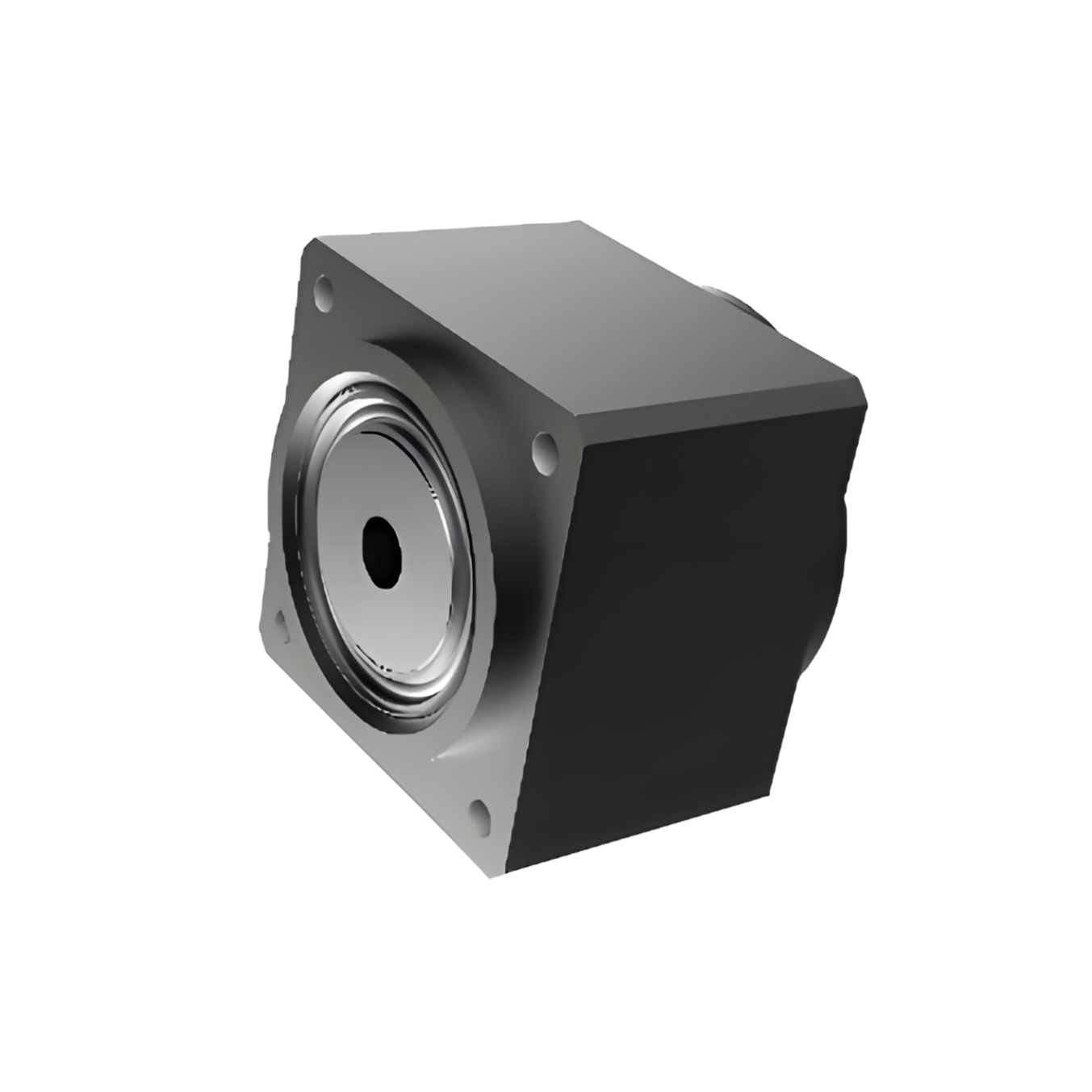

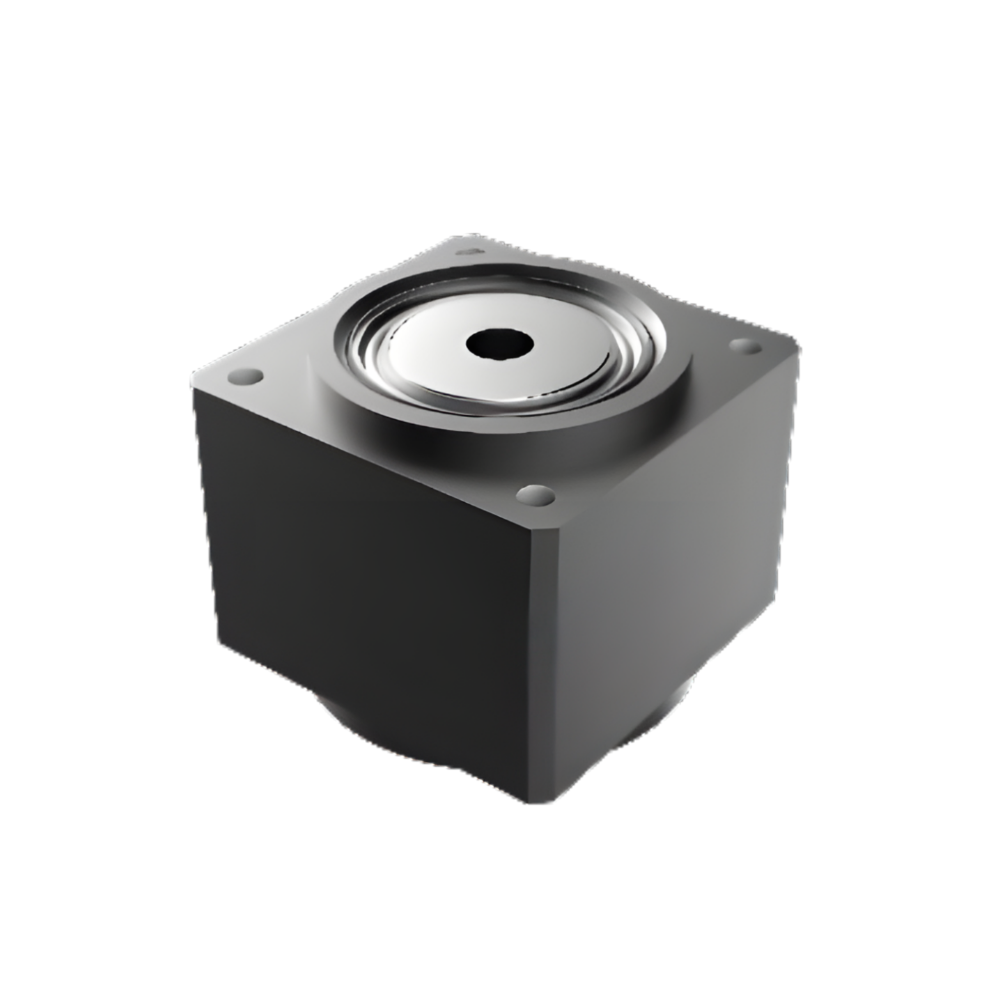

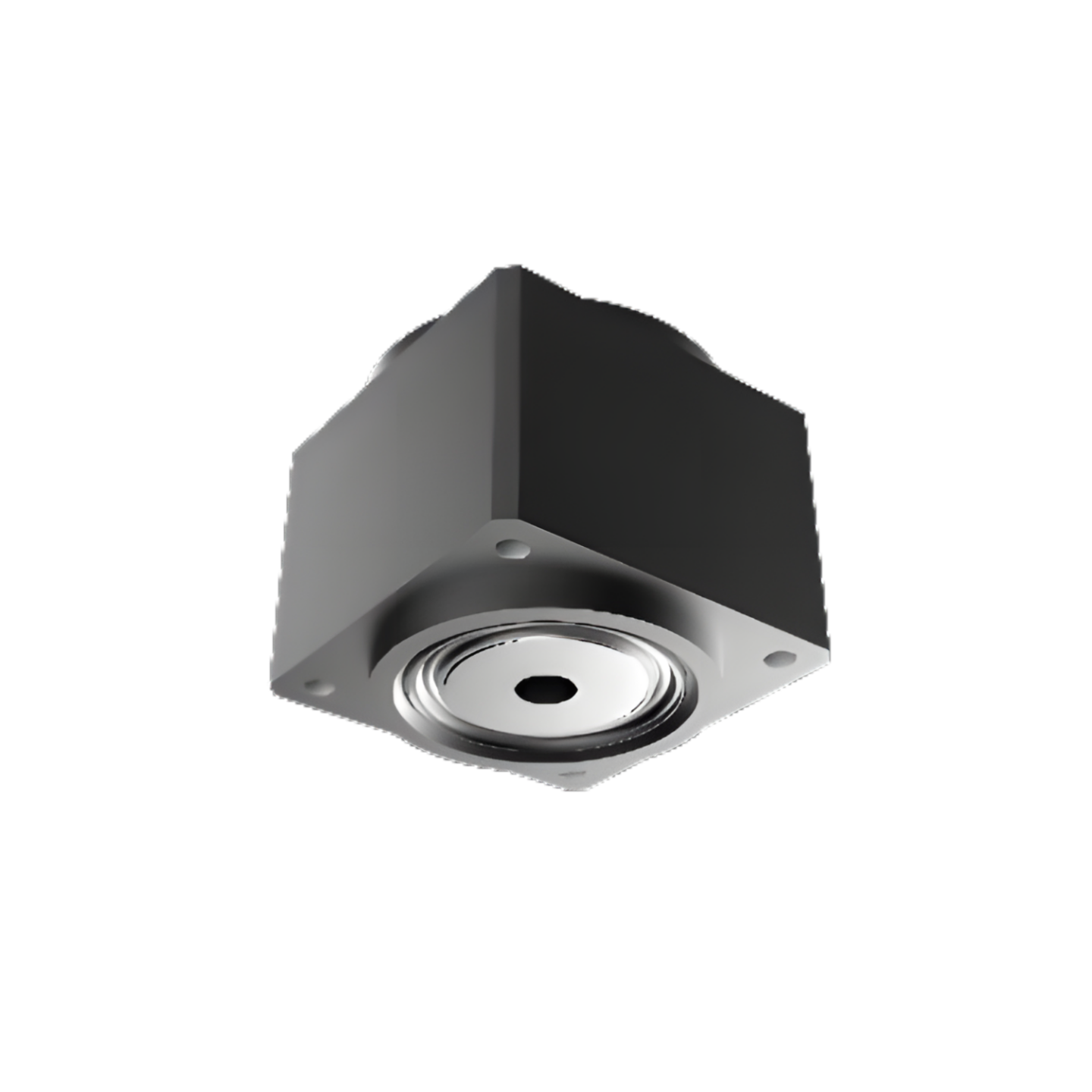

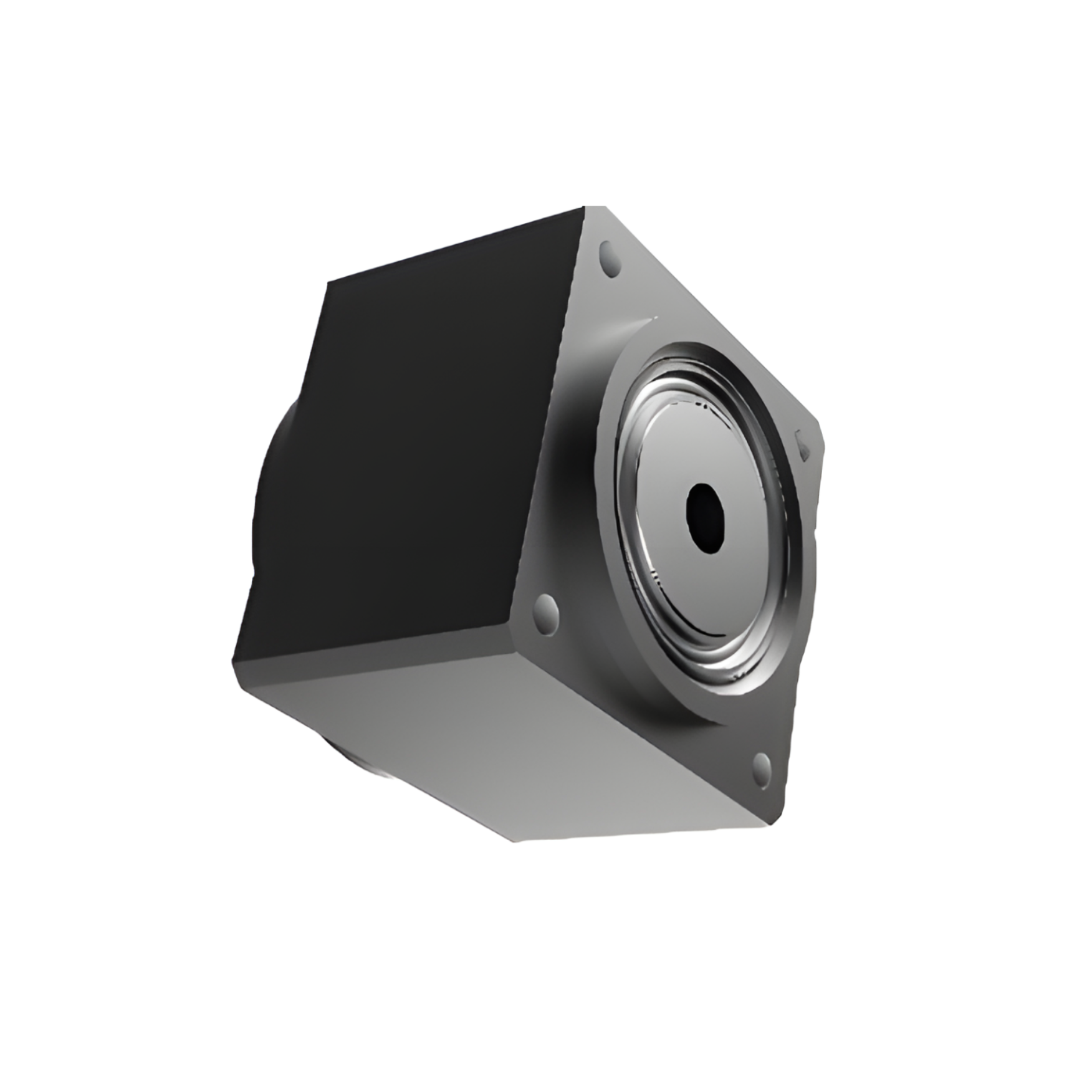

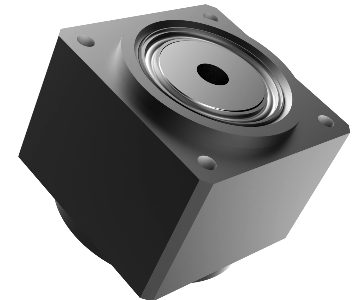

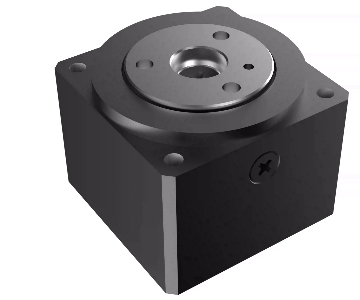

Product Display

As an extremely sophisticated transmission mechanism, harmonic drive achieves motion transmission and conversion through wave deformation. When the wave generator is introduced and acts on the flexible wheel, the flexible wheel will produce corresponding continuous wave deformation according to the specific shape and motion law of the wave generator, and realize complex and diverse motion conversion requirements such as converting high-speed rotational motion into low-speed high-torque motion, or converting linear motion into specific curve motion.

With the rapid development of science and technology, harmonic drive technology is also constantly evolving. The research and development and application of new materials have brought more excellent mechanical properties and durability to components such as flexible wheels, enabling them to operate stably under more stringent working conditions. At the same time, the introduction of advanced manufacturing processes such as precision CNC machining and special molding technology has made a qualitative leap in the manufacturing accuracy and production efficiency of harmonic drive devices, further reducing production costs and improving the market competitiveness of products.

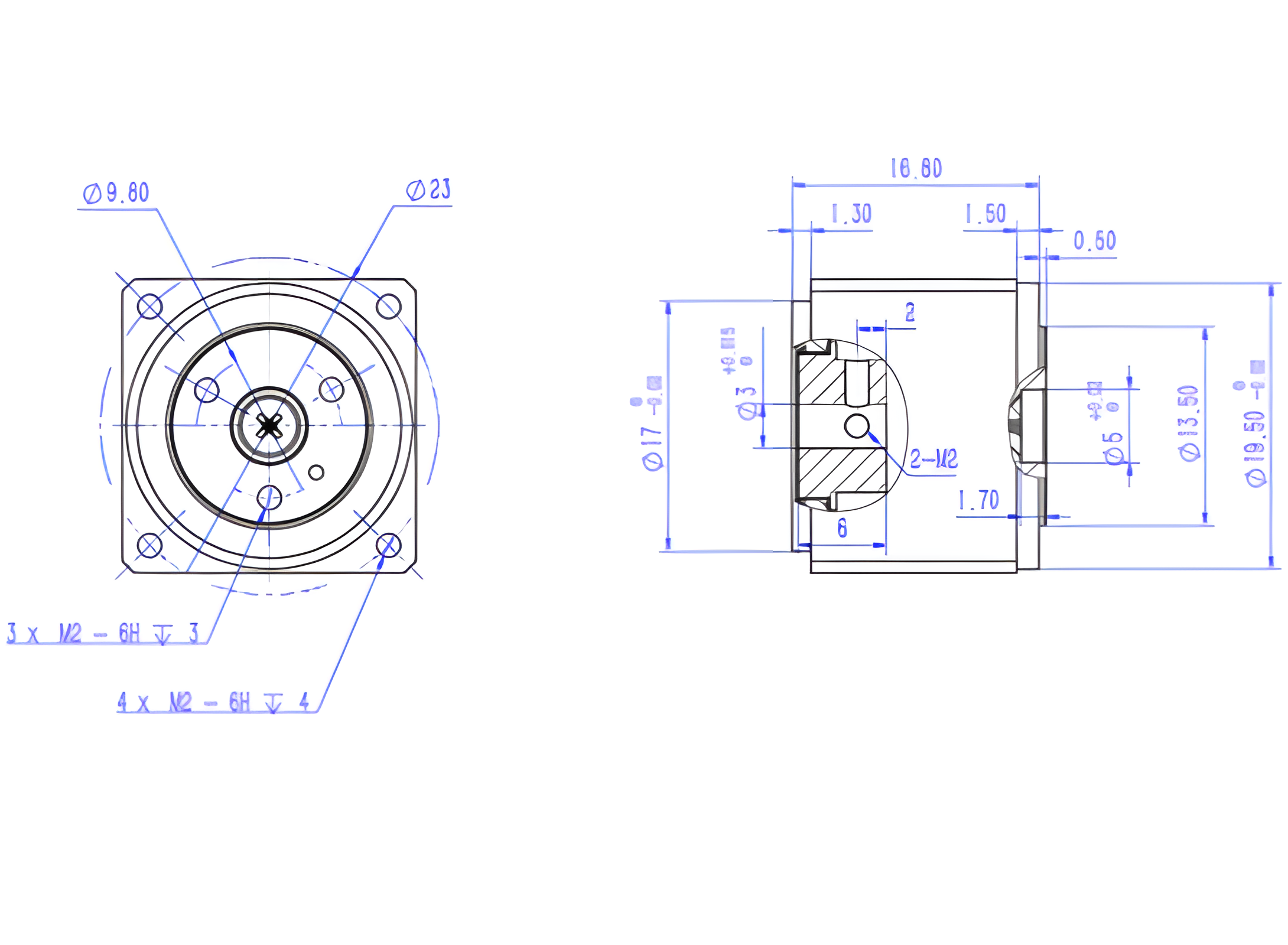

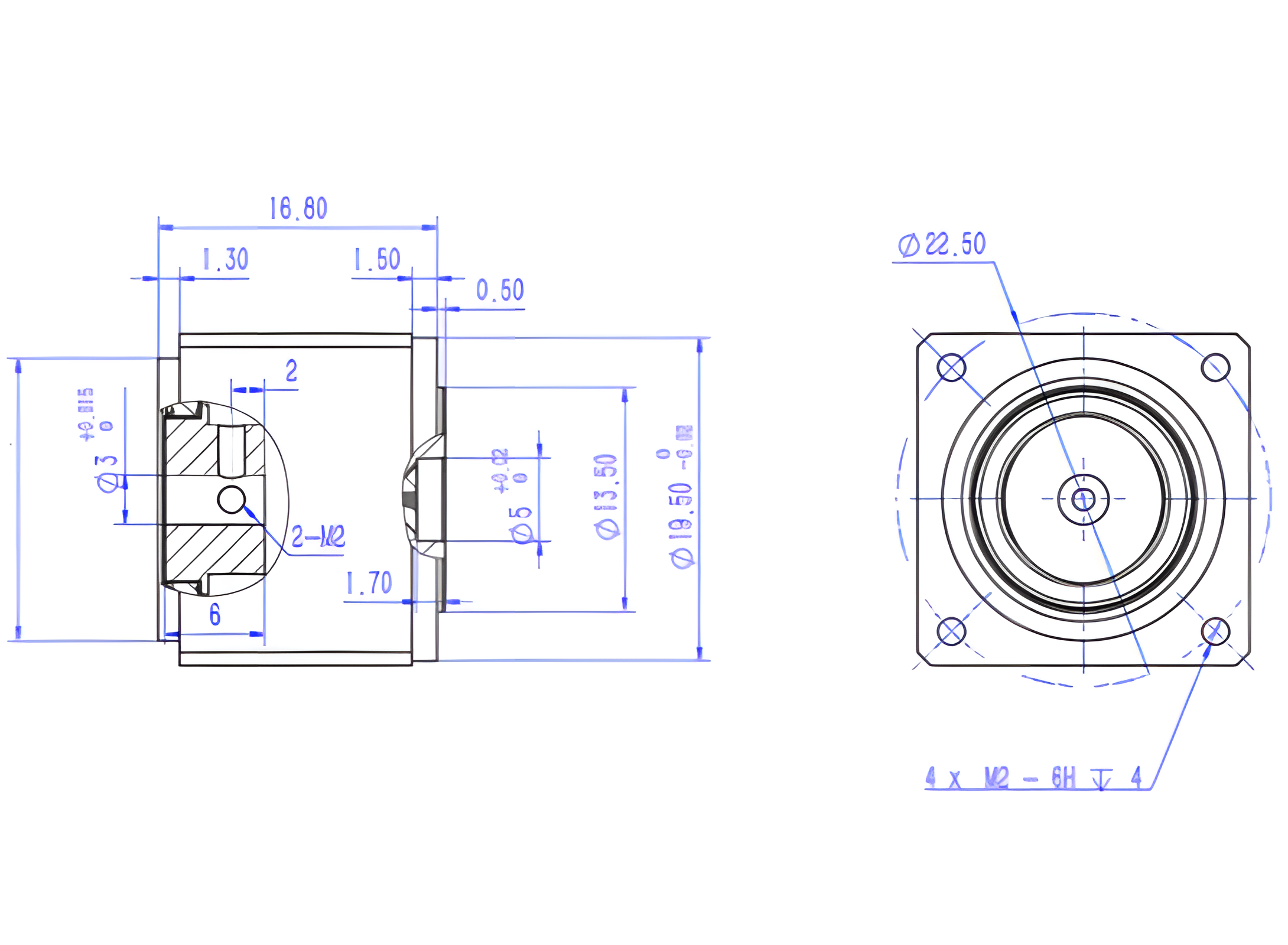

Size & Interface

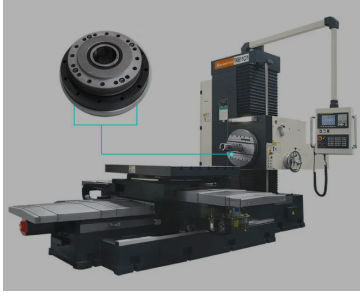

Application Cases

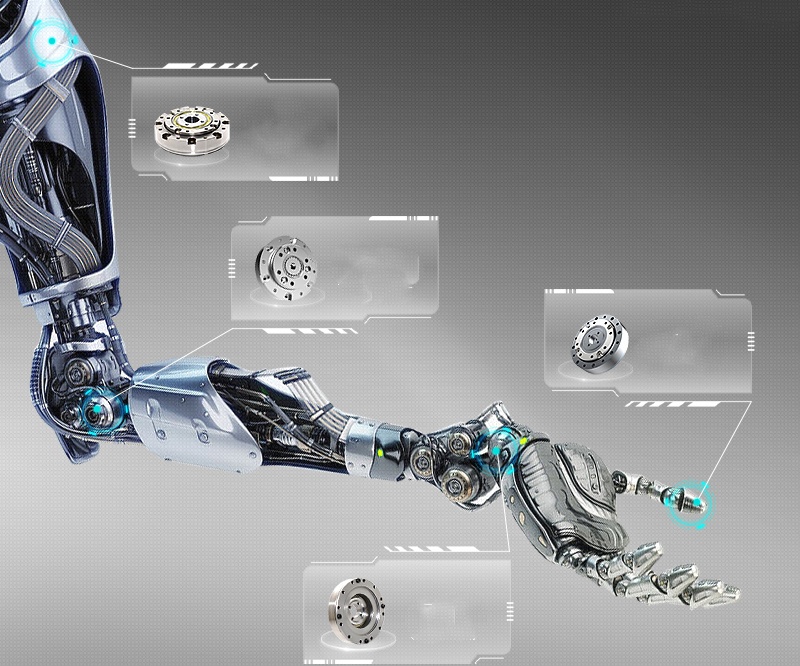

The harmonic reducer is small in size and light in weight, and can be installed in the small space of the robot hand to provide precise power transmission and motion control for the hand joints, allowing the robot hand to achieve flexible movements. In addition, the low vibration and low noise characteristics of the harmonic reducer also help reduce vibration and noise during hand joint movements, improving the operational stability and quietness of the robot. The limbs of humanoid robots need to complete various complex and delicate movements, such as grabbing objects, walking, climbing, etc. The harmonic reducer has high transmission accuracy, which can ensure that the robot's limb joints accurately reach the predetermined position and achieve high-precision motion control.