Product Description

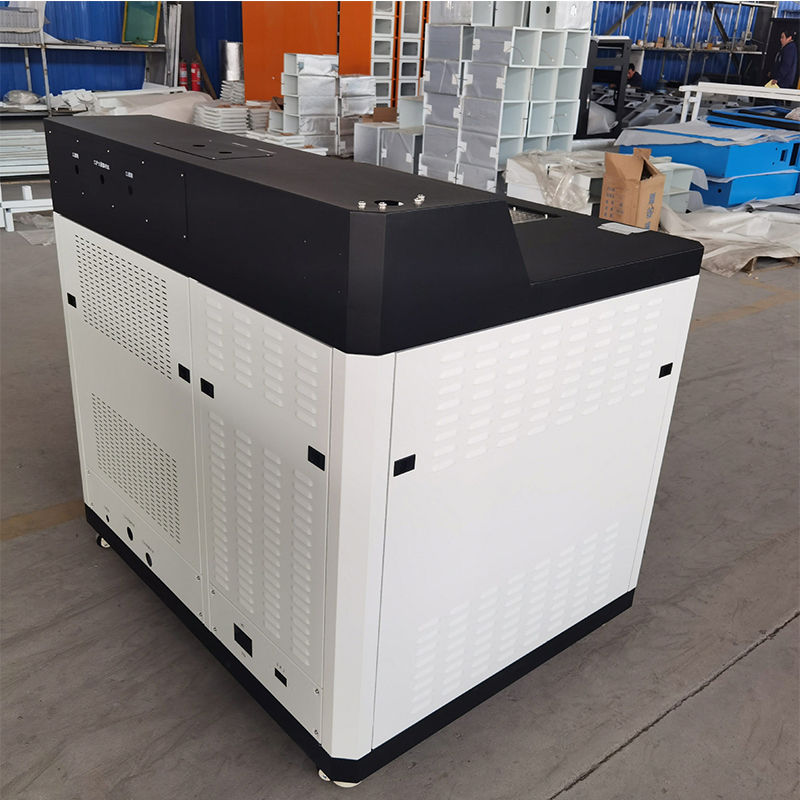

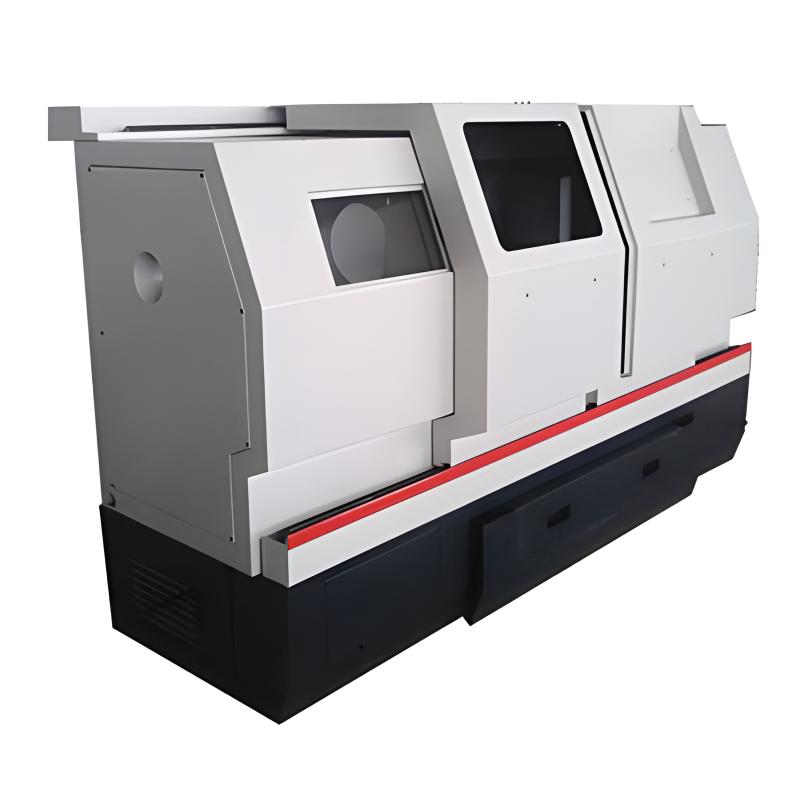

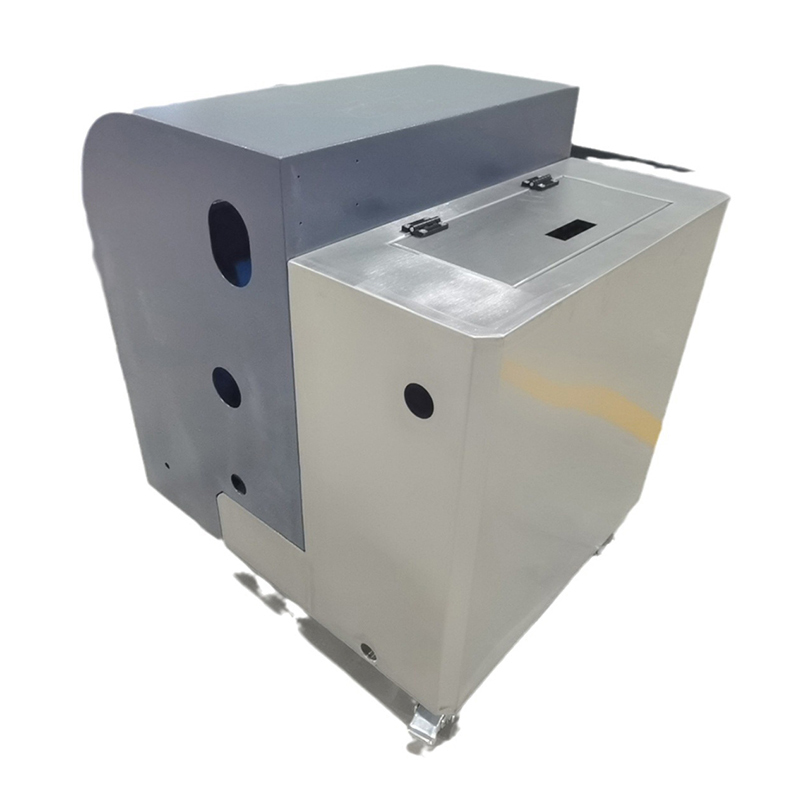

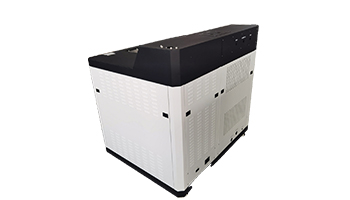

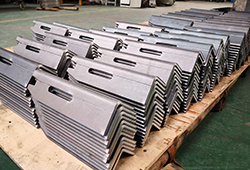

The sheet metal cabinet consists of the base, top cover, front and rear doors, front and rear frames, side doors, Angle gauges, and beams. The main frame is formed by bending and welding repeatedly to ensure high strength of the cabinet, ensure stable operation of devices, and provide reliable support and protection for internal devices.

Product parameters

| name | argument | name | argument | name | argument |

|---|---|---|---|---|---|

| name | Cabinet sheet metal | material | Stainless steel, aluminum plate, iron plate | Surface treatment technology | Sandblasting, polishing, other |

| Sheet thickness | custom(mm) | Processing size/Length * width * height | custom(mm) | Dimensional accuracy | ±1mm |

| Molded part | Equipment hood housing | Blanking method | NC numerical control blanking | Machinable thickness | 0.1-15.0mm |

| Surface treatment | Baking paint | Surface roughness | custom | Sheet metal technology | Laser cutting, blanking, welding |

| Proofing cycle | Seven days | Processing cycle | 8 to 15 days | Whether assembly services are available | Provide assembly services |

| Application field | Electricity, industrial equipment, utilities | specification | Machine tool sheet metal consulting customer service | Maximum/small machining size | custom |

Custom Process

Consultation + Sample

Final design

Order and pay

Confirmed sample

production

Logistics delivery

Process Type

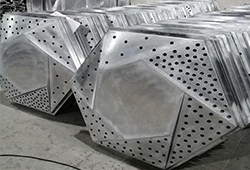

Laser cutting: The use of high energy density laser beam irradiation sheet metal material, so that the material quickly melt or vaporize, so as to achieve cutting. This method has high cutting precision, can cut very complex shapes, and the cutting surface is relatively smooth.

Mechanical bending: Use a bending machine to bend sheet metal. By adjusting the mold and pressure of the bending machine, the sheet metal material can be folded into various angles. In the bending process, according to the thickness of the sheet metal material, material and bending Angle to choose the appropriate mold and bending process parameters.

Welding process: low cost, high production efficiency, suitable for medium and thick plate welding. In the welding of sheet metal structure of large machine tools, such as the welding of machine tool base, carbon dioxide gas shielded welding is widely used.

Material

Aluminium alloy

alloy

High quality carbon steel

Cold-rolled sheet

Quality Control

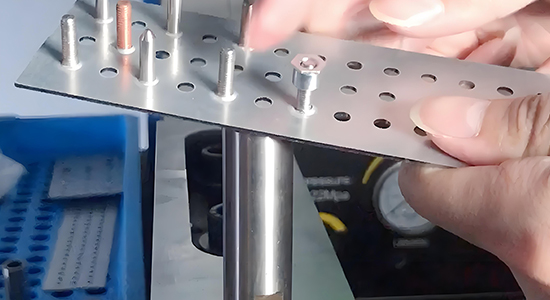

Our products are customized products before shipment, we will pass special QC quality inspection to ensure product quality: Our products are customized products before shipment, we will pass special QC quality inspection to ensure product quality.

Processing capability

The company has fiber laser cutting machine, CNC NCT punching machine, CNC folding machine, CNC hydraulic riveting machine, pressure forming machine, wire drawing machine, laser welding machine, spot welding machine, cold welding machine, argon arc welding machine, carbon dioxide welding machine, aluminum welding machine, painting and spraying equipment and other sets of sheet metal and testing equipment, and is equipped with a professional 3D sheet metal process design team.

Additional processes

Riveting: Joining two or more sheet metal parts together by rivets. After the rivet passes through the pre-drilled hole, one or both of its ends are deformed with a special tool to form a firm connection. This connection has a certain degree of reliability and shock resistance, and is often used in some cases where the connection strength is not particularly high, but a simple and quick connection is required, such as the assembly of some simple metal shelves.