Product Description

This solid articulated motor combines a dc torque motor, driver, encoder and high precision harmonic reducer. M Series joint actuators make automated production easier and more efficient. It can be widely used in CNC machine, automated production lines, robot arms, humanoid robots, large rotating platforms. This product has stable performance and fewer after-sales problems, making it the first choice for robot customers.

Product parameters

| Parameter | M4210E11B50L | |

| Overall parameter | Motor rated voltage | 24~36VDC |

| Motor rated current | 1.5A | |

| Output torque after deceleration | 3.2NM | |

| Weight | 0.4KG | |

| Speed range after deceleration | 0~40RPM | |

| Reducer parameter | Reduction ratio | 50 |

| Rated torque | 3.2NM | |

| Peak start-stop torque | 7.8NM | |

| Backlash | <10 arc seconds | |

| Design life | 8500hour | |

| Motor parameter | Torque | 0.3NM |

| Rated speed | 2000RPM | |

| Maximum rotational speed | 2500RPM | |

| Power | 33W | |

| Resistance | 2.65 | |

| Inductance | 1.18mh | |

| Rotary inertia | 9.139x10-5 KG/M 2 | |

| Feedback signal | Multi-turn absolute encoder (15 bit single-turn and 16 bit multi-turn) | |

| Cooling mode | Natural cooling | |

| Position Control Mode | Maximum input pulse frequency | 500KHz |

| Pulse instruction mode | Pulse + direction, A phase +B phase(needs the controller supports AB pulses) | |

| Electronic gear ratio | Set up 1~65535 to 1~65535 | |

| Location sampling frequency | 2KHZ | |

| Protection function | Lock-motor alarm, over-current alarm | |

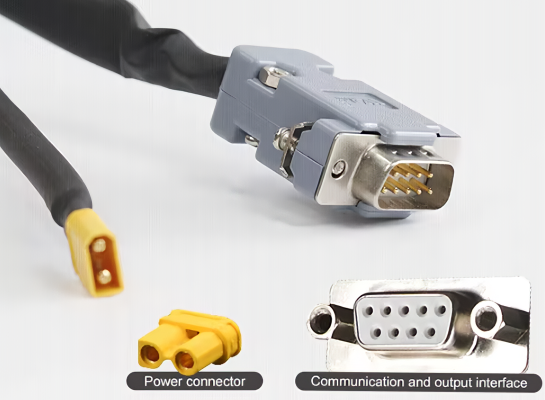

| Communication interface | Canopen (CAN Communication) /Modbus(485 communication) | |

| Environment | Ambient temperature | 0~40° |

| Max. permissible temperature of motor | 85° | |

| Humidity | 5~95% | |

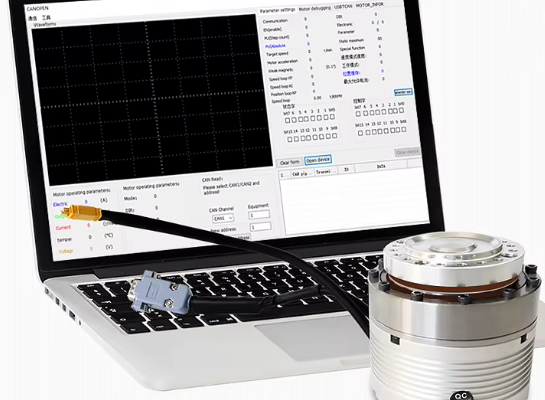

Product Display

Support SDO TPDO RPDO

In the joint module, the host software using CANopen protocol can effectively manage and monitor the motor state of each joint and modify the related parameters.

Monitor motor running status, speed and torque monitoring, modify motor speed parameters, torque limit modification, position monitoring parameters modification

- When the motor is powered, there is a charging circuit inside to charge the battery

- After the motor is not powered, the motor shaft is driven to rotate to wake up the encoder and continue to memorize the position the battery current consumption is only 0.07mA

- Battery power down alarm

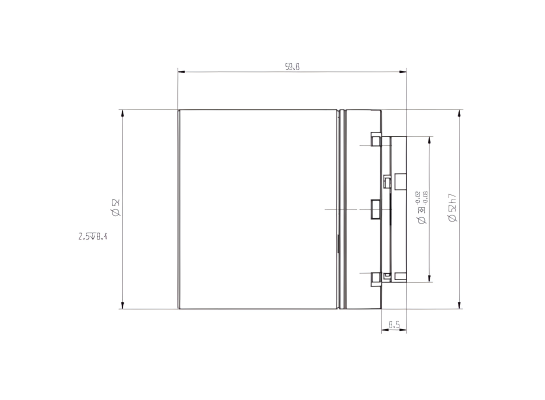

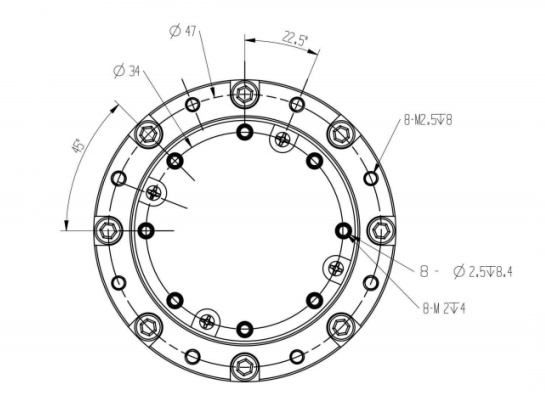

Size & Interface

Application Cases

This series of joint module actuators can be applied to industrial robots, collaborative robot arms, bipedal and quadruped bionic robots, medical robots (surgery and rehabilitation robots, etc.),AGV vehicles, fruit and vegetable picking robot arms, camera head and so on.