Product Description

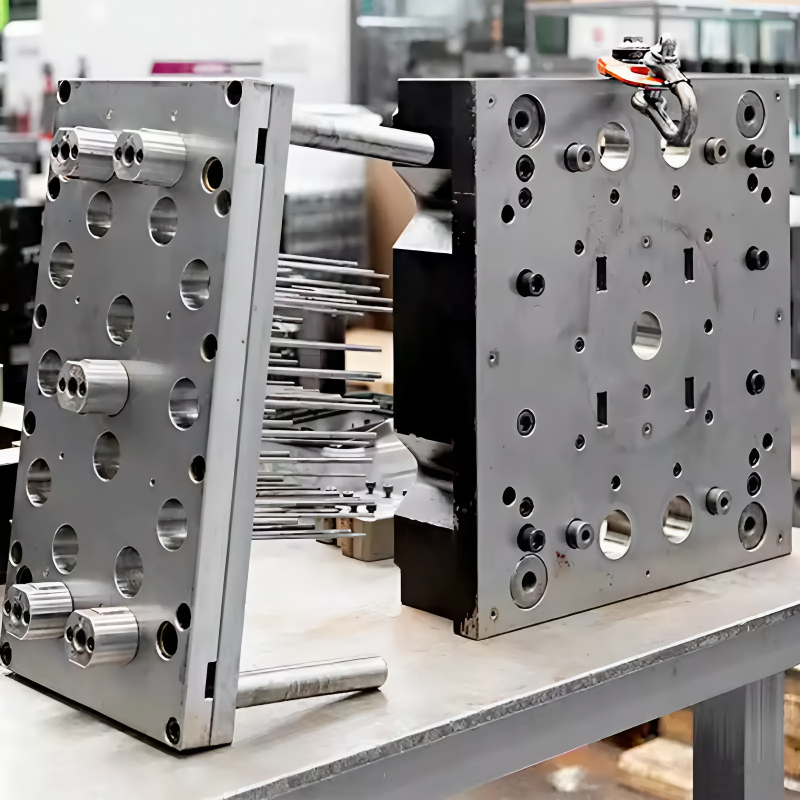

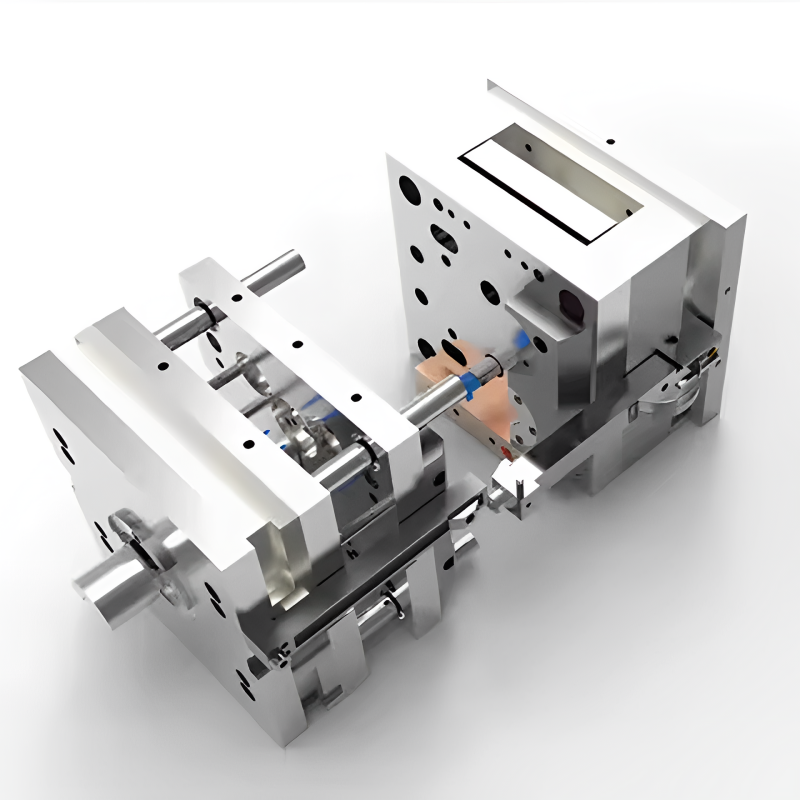

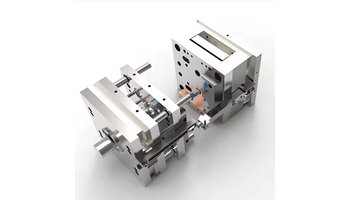

This custom plastic injection mold for scraper tools is designed to deliver precision and durability for various applications. Crafted with high-quality materials, it ensures consistent performance, enabling the production of scraper tools with a smooth finish, accurate dimensions, and robust construction. The mold supports customization to meet specific design requirements, making it ideal for industries such as construction, automotive, and home improvement. Its advanced engineering guarantees efficient production cycles, reducing waste while maintaining exceptional quality. Whether for large-scale manufacturing or specialized small-batch runs, this mold is a reliable solution for creating professional-grade scraper tools.

Product parameters

| Category | Details |

|---|---|

| Processing | Turning, Milling, Drilling, Tapping, Knurling, Wire EDM, Grinding, Engraving, etc. |

| Tolerance | +/-0.005mm or Custom |

| Mold Material | Stainless steel, aluminum, copper: S136H, 718H, 2343, 8407, NAK80, P20, H13, #50 steel, etc. |

| Material Workable | PEEK, ABS, Teflon, Acrylic, Delrin, PP, PMMA, PC, POM, Polyethylene, PVC, Nylon. Other materials as requested. |

| Surface Treatment | Nickel Plating, Anodizing, Chrome Plating, Brushing, Polishing, Blackening, Powder coating, Sandblasting, De-burring, Electrophoresis, Passivation, etc. |

| Drawing Format | JPEG, PDF, DWG, DXF, IGS, STEP, CAD |

| MOQ | No MOQ Required |

| Size | Customization |

| Standard | OEM/ODM |

| Packing | Carton box, wooden case, pallet, etc. |

| Shipping | By sea, by air, by DHL, UPS, FedEx, TNT, or EMS |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Plastic Fan Blades

Reason

Car Mudguard

Reason

Washing Machine Panels

Reason

Material

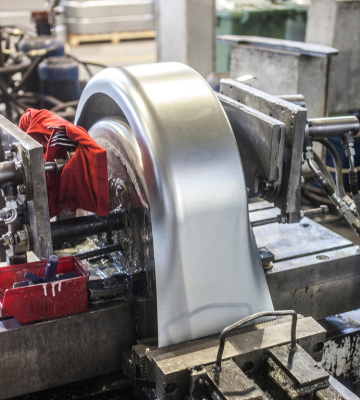

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for custom plastic injection molded scraper tools involves inspecting raw materials, ensuring dimensional accuracy, and checking for surface defects. Tools undergo stress testing to confirm durability, and final products are measured for precision using tools like CMMs. Continuous inspections ensure reliability and meet customer specifications.

Processing capability

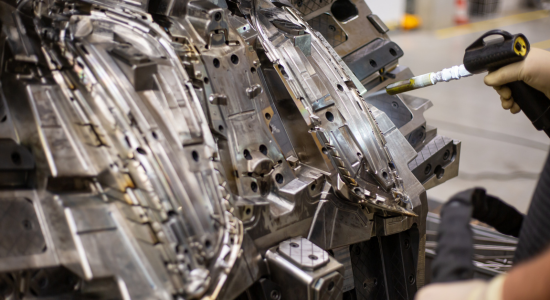

The processing capability for custom plastic injection molded scraper tools includes the use of advanced injection molding machines to produce precise and durable components. These tools are created using high-quality molds that ensure consistent production with tight tolerances. The process involves the selection of suitable materials, such as thermoplastics or specialized polymers, to enhance the tool's strength and flexibility. With capabilities like multi-cavity molds and automation, the factory can efficiently produce large volumes while maintaining high precision. Advanced techniques such as overmolding and insert molding may also be used for added functionality, and post-processing options like surface finishing and coating are available to meet specific customer requirements.

Additional processes

Additional processes for custom plastic injection molded scraper tools include surface finishing, such as polishing, coating, and texturing, to enhance durability and appearance. Secondary operations like assembly, engraving, and packaging are also provided to ensure the tools are ready for use. These processes help meet specific functional and aesthetic requirements while ensuring the final product is of high quality and fully operational.