Product Description

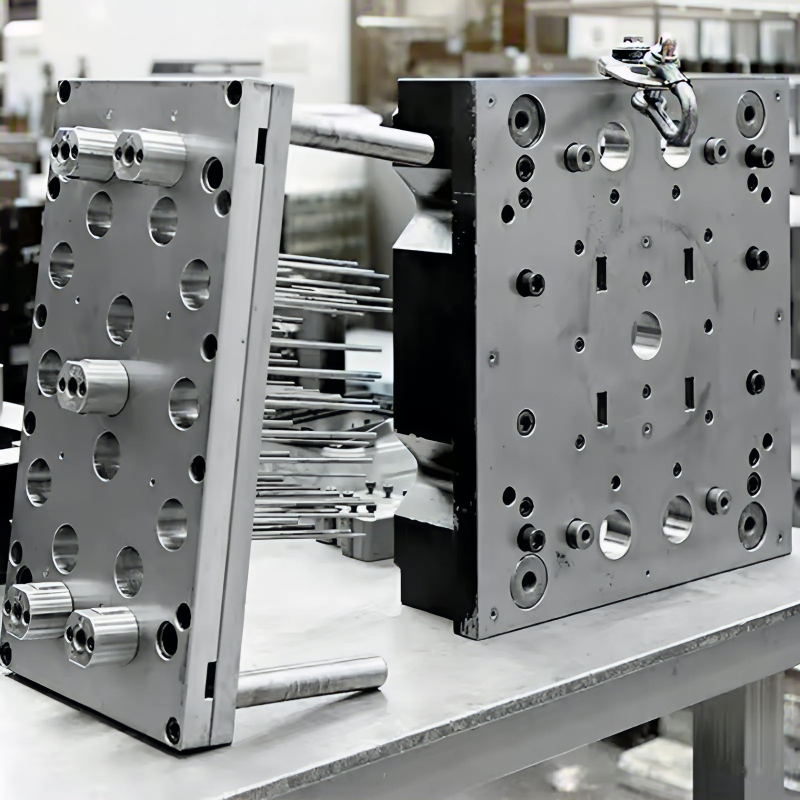

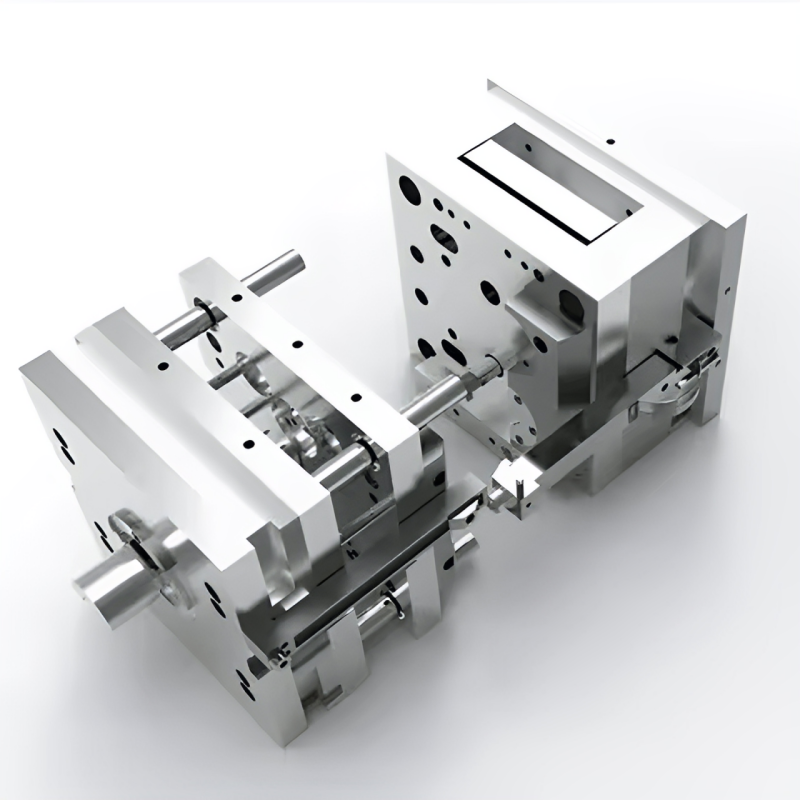

Our custom mold plastic injection molding tool service provides tailored solutions to produce high-quality plastic components with precise designs. Using advanced technology, we create molds to meet your specific needs, ensuring durability and optimal performance. We work with various materials and focus on precision, efficiency, and consistent quality for both large-scale and small-batch production.

Product parameters

| Category | Details |

|---|---|

| Processing | Turning, Milling, Drilling, Tapping, Knurling, Wire EDM, Grinding, Engraving, etc. |

| Tolerance | +/-0.005mm or Custom |

| Mold Material | Stainless steel, aluminum, copper: S136H, 718H, 2343, 8407, NAK80, P20, H13, #50 steel, etc. |

| Material Workable | PEEK, ABS, Teflon, Acrylic, Delrin, PP, PMMA, PC, POM, Polyethylene, PVC, Nylon. Other materials as requested. |

| Surface Treatment | Nickel Plating, Anodizing, Chrome Plating, Brushing, Polishing, Blackening, Powder coating, Sandblasting, De-burring, Electrophoresis, Passivation, etc. |

| Drawing Format | JPEG, PDF, DWG, DXF, IGS, STEP, CAD |

| MOQ | No MOQ Required |

| Size | Customization |

| Standard | OEM/ODM |

| Packing | Carton box, wooden case, pallet, etc. |

| Shipping | By sea, by air, by DHL, UPS, FedEx, TNT, or EMS |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

TV or Monitor FramesReason

Reason

Refrigerator Trays

Reason

Cable Trunking

Reason

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for our custom mold plastic injection molding tool service ensures that each mold meets precise specifications and high standards. We conduct thorough inspections of raw materials and verify dimensional accuracy throughout the production process. Each mold undergoes rigorous testing for durability, functionality, and surface quality, with automated and manual checks to detect any defects. Final products are measured using precision tools, ensuring they align with customer requirements and industry standards. This process guarantees reliable, high-performance molds every time.

Processing capability

The processing capability of our custom mold plastic injection molding tool service includes advanced mold design, precision machining, and high-quality production techniques. We utilize state-of-the-art injection molding machines and multi-cavity molds to produce complex parts with tight tolerances. Our service supports a wide range of materials, including thermoplastics and specialized polymers, to meet diverse customer needs. We also offer capabilities for automation, overmolding, insert molding, and custom surface finishes, ensuring efficiency, consistency, and high-quality results in both large and small production runs.

Additional processes

Additional processes for our custom mold plastic injection molding tool service include surface finishing options like polishing, coating, and texturing to enhance durability and appearance. We also offer secondary operations such as assembly, engraving, and quality inspections to ensure each mold meets customer specifications. Post-production services, including packaging and custom labeling, are available to provide a complete solution for your molding needs. These processes ensure that every tool is not only functional but also meets specific aesthetic and performance requirements.