Product Description

Precision casting is an advanced casting process used to manufacture high-precision, high-quality metal parts.

Definition and purpose:

Precision casting is mainly through a series of fine process, so that the cast parts in dimensional accuracy, surface quality and mechanical properties can reach a high standard, to minimize the amount of subsequent mechanical processing, and even some precision castings can be used directly, without reprocessing.

Product parameters

| name | argument | name | argument |

|---|---|---|---|

| Product name | Precision casting part | Product technology | Gravity casting |

| Product material | Cast iron gray iron cast steel spheroidal ink | Product characteristics | High stiffness and hardness are not easy to wear |

| Product specification | Various specifications are customized | Scope of application | Machinery manufacturing chemical industry hardware petroleum automobile metallurgy etc |

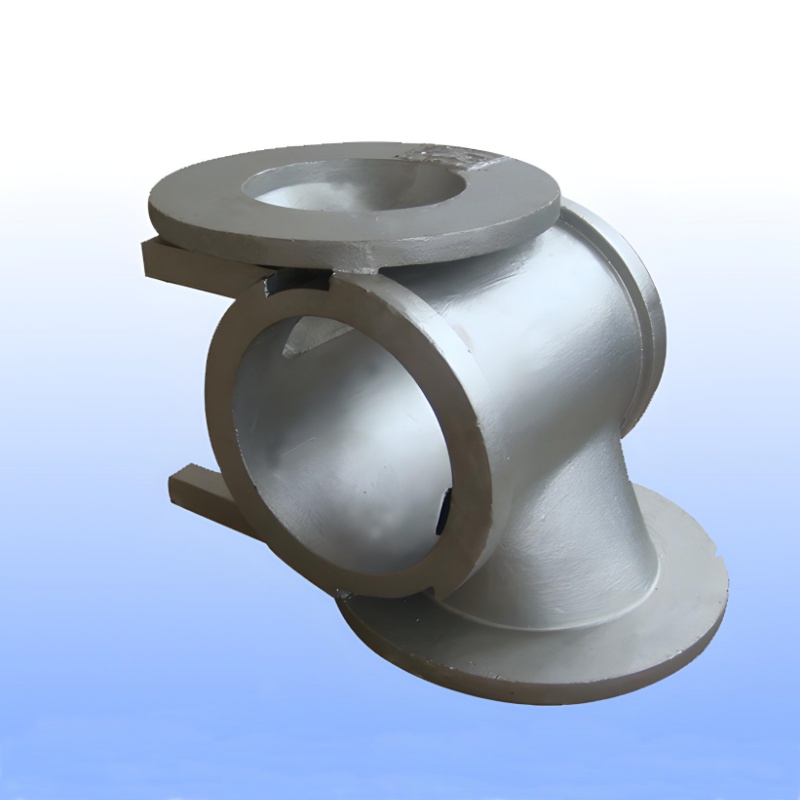

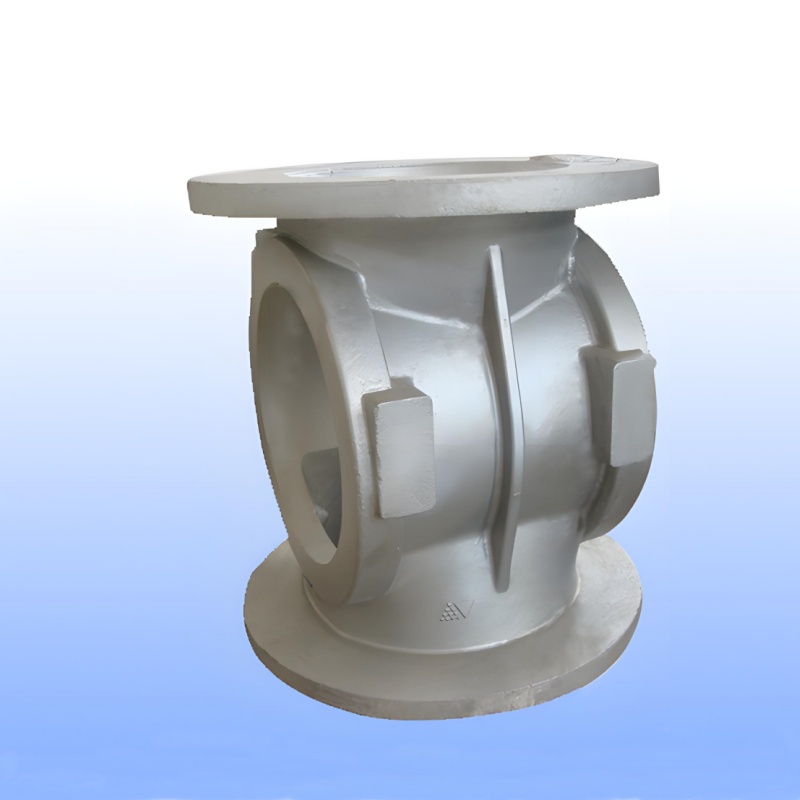

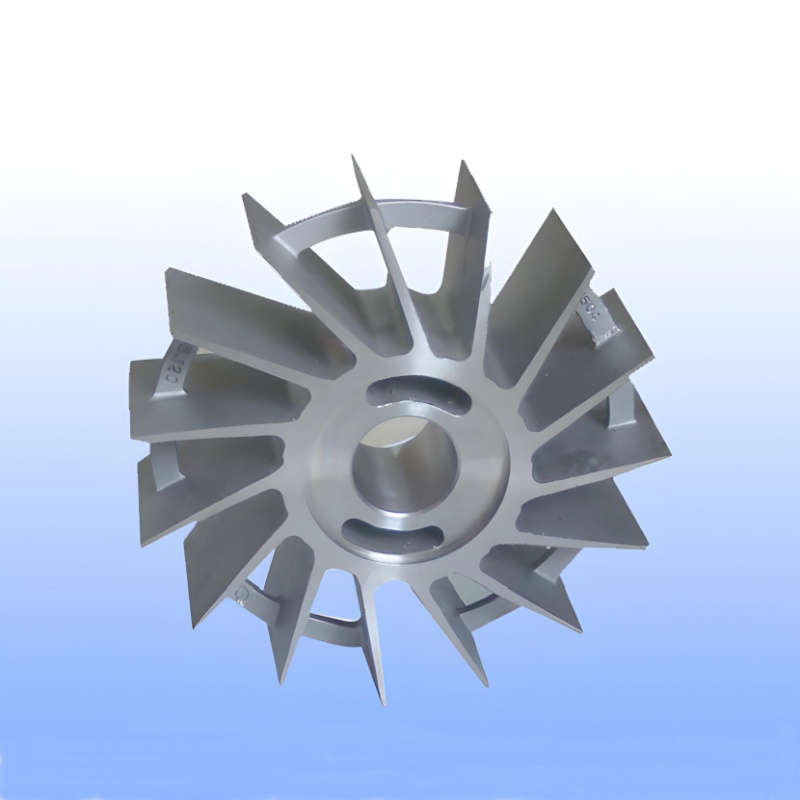

Product Display

High dimensional accuracy

The dimensional tolerance level of precision casting parts can generally reach the CT4-CT7 level (CT is the standard of casting tolerance level), and some processes can even be higher. Compared with the traditional casting process, precision casting can better control the size of the part and reduce the size deviation. For example, in the casting of metal housings for electronic devices, precision casting can ensure that the dimensions of the housings are accurate, so that the electronic components can be accurately installed.

Good surface quality

The surface roughness of the casting can reach Ra0.8-Ra3.2μm (Ra is the evaluation parameter of surface roughness). This makes the casting look beautiful, which is very advantageous in the manufacture of some products with high appearance requirements, such as jewelry and crafts. And good surface quality can also reduce parts in the use of friction, wear and other problems.

Quality Control

In precision casting, quality control is very important. From the strict screening of raw materials to ensure the high quality of metal and refractory materials; To fine control of the process, accurate mold production, perfect preparation of shell, precise control of pouring; To the comprehensive quality inspection, the appearance inspection is detailed, the size measurement is accurate, the mechanical properties are strictly tested, and the metallographic analysis is insight. At the same time, continuous improvement will never stop, optimize the process through quality data analysis, strengthen personnel training to enhance quality awareness. With strict quality control, casting precision casting excellent quality.

Application Cases

Precision casting, a wide range of applications, covering machinery manufacturing, chemical, hardware, petroleum, automotive, metallurgy and many other fields, with superb technology to achieve excellent quality, to provide solid support for the development of various industries.