Product Description

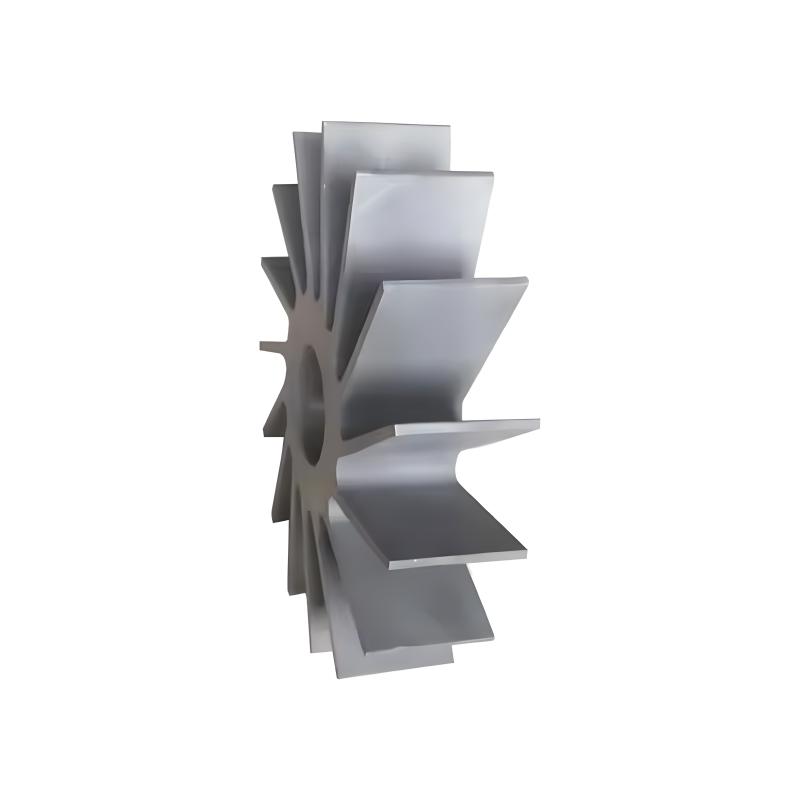

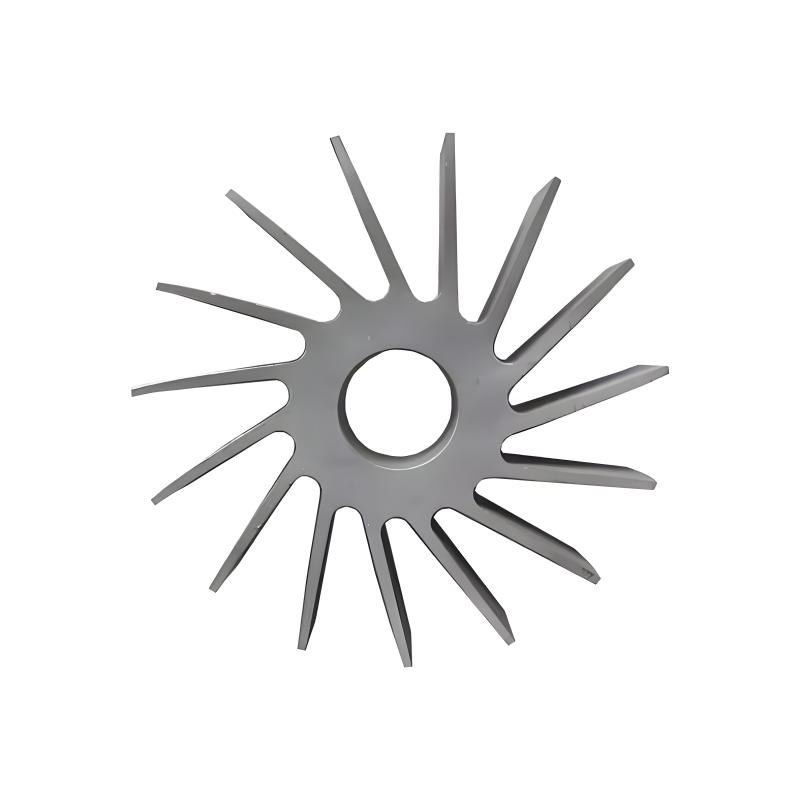

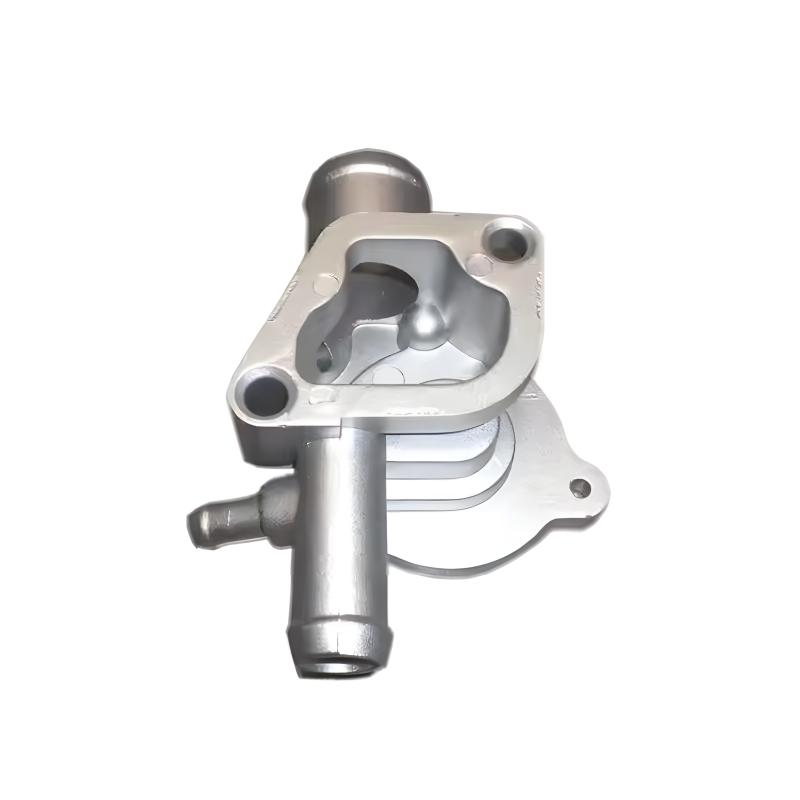

It can manufacture castings with extremely complex shapes, such as parts with internal cavities, thin walls, fine blades, complex curved surfaces and other structures. Because the production of wax mold is relatively flexible, various shapes of wax mold can be made by mold or hand, and then the shell is formed by coating and sand, so as to achieve the casting of complex shapes. For example, the complex internal cooling channels and fine shape of aero-engine blades can be achieved by precision lost-wax casting.

Product parameters

| name | argument | name | argument |

|---|---|---|---|

| allowance | 0.05 ~ 0.2 mm | Product technology | Gravity casting |

| flow | Die casting + machining | service | OEM\ODM |

| Product specification | Various specifications are customized | Application field | Machinery manufacturing chemical industry hardware petroleum automobile metallurgy etc |

Technological Innovation

Wax molding:

First, a precision machined mold is used to make the wax mold. Wax molding materials are usually special wax or plastic, which can accurately reproduce the shape of the desired casting. The dimensional accuracy of the wax mold is very high, because it directly determines the dimensional accuracy of the final casting. For example, in aerospace parts casting, dimensional tolerances of wax molds can be controlled to a very small range to ensure that the final part meets strict design requirements.

Wax mold production can be achieved in a variety of ways, such as injection molding, melting wax material is injected into a metal mold at a certain pressure, and the shape of the wax mold is accurate after cooling; Or the use of hand-carved wax mold, for some small batch production or with special shape requirements of the wax mold, manual production can better meet the design details.

Product Display

Smooth surface

Ingenuity built to last a long time

Smooth and trachomato-free multi-layer process, better corrosion resistance

More use of seiko fine pecking surface smooth exquisite appearance more exquisite

Durable and reliable material

Our stainless and carbon steel alloy steel materials are known for their durability and reliability, making them suitable for a variety of industrial applications.

Quality Control

In order to ensure that every silica sol investment casting product can meet the high quality standards, we have established a strict quality assurance system. From the selection of raw materials to the monitoring of the production process, to the inspection of the finished product, every link is strictly checked.

Application Cases

Precision casting, a wide range of applications: covering machinery manufacturing, chemical industry, hardware, water conservancy, petroleum, automotive, metallurgy and many other fields, with superb technology to achieve excellent quality, to provide solid support for the development of various industries.