Product Description

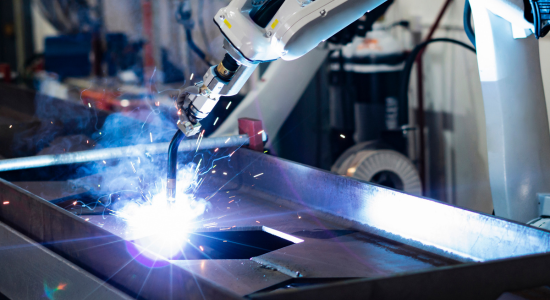

Our aluminum welding fabrication service uses advanced techniques like TIG and MIG welding to join or shape aluminum for various applications. Known for its lightweight, durability, and corrosion resistance, aluminum is ideal for automotive, structural, and consumer products. We deliver high-quality, precise welds for both small and large-scale projects.

Product parameters

| Material : | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc 3). Steel: 4140, Q235, Q345B,20#,45# etc. 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish,Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing,electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

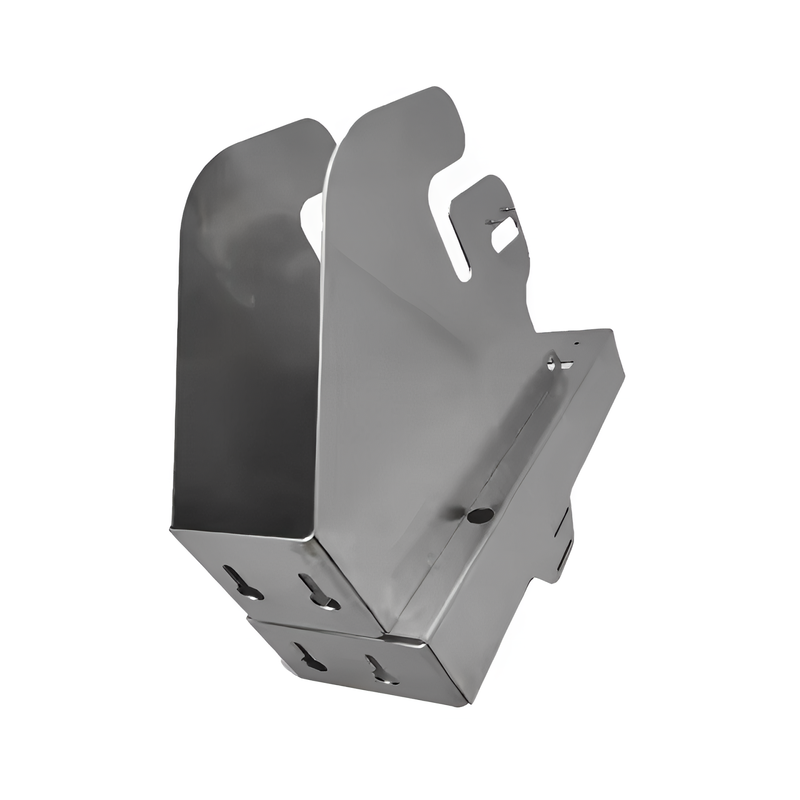

Automotive Mounts or Housings

Reasons

- High Precision: These metal components require accuracy, making them ideal for automotive parts.

- Vibration Resistance: Able to withstand vibrations from engines or suspension systems

Appliance Components

Reasons

- Suitable for Accessory Production: Used for securing internal parts like wiring brackets in washing machines, dryers, or refrigerators.

- Sleek and Simple Appearance: When polished or coated, these components are perfect for visible consumer products.

- Cost-Effective Production: Can be manufactured efficiently through metal stamping for large quantities.

Storage Rack Components

Reasons

- Weight-Bearing Design: The curved or reinforced bent shapes of the components make them ideal for supporting weight in storage systems.

- Multi-Point Connections: Multiple holes or slots allow for adjustable racks or additional accessories.

- Mass Production Friendly: These components can be replicated with consistency, reducing production costs.

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in aluminum welding fabrication ensures structural integrity and compliance with standards by inspecting materials, preparing surfaces, and adhering to precise welding parameters. Post-welding checks, including visual and advanced testing, verify weld quality and dimensional accuracy. Proper environmental controls and equipment monitoring maintain consistency, with thorough documentation for traceability.

Processing capability

The processing capability of aluminum welding fabrication includes TIG and MIG welding for precise, strong joints, along with cutting, shaping, and surface preparation. Skilled operators and advanced machinery ensure tight tolerances and intricate designs. Post-welding treatments like grinding and polishing enhance durability and appearance, making it ideal for industries such as automotive, aerospace, and construction.

Additional processes

Additional processes in aluminum welding fabrication include surface cleaning, heat treatment to relieve stress, and finishing techniques like polishing, anodizing, or coating for enhanced appearance and corrosion resistance. Precision machining and assembly may also be performed to meet specific design and tolerance requirements.