Product Description

We specialize in high-quality sheet metal fabrication for various industries. Our services include cutting, bending, welding, punching, and custom surface treatments such as powder coating, anodizing, and plating. We manufacture parts for enclosures, brackets, panels, and frames, ensuring precision and durability in every product. Customization options include size, thickness, and finish, tailored to meet specific requirements.

Product parameters

| Product name | Custom CNC Machining Parts |

| Surface treatment | Grinding/ Polishing/ Oil Spray/ Screen Printing/ Radium Carving/ Electroplating/ Oxidation Etc |

| Customized | Customized Color, Size, Hardness, Logo, Packaging |

| Service | Custom Machining CNC Services |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

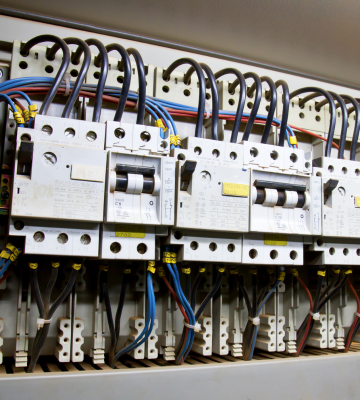

Enclosure or Panel Cover for Control Systems

- Reason for use: These metal parts can be used as components in durable control panels, such as those used in the automotive or electronics industry, to protect circuits from dust, moisture, or physical damage.

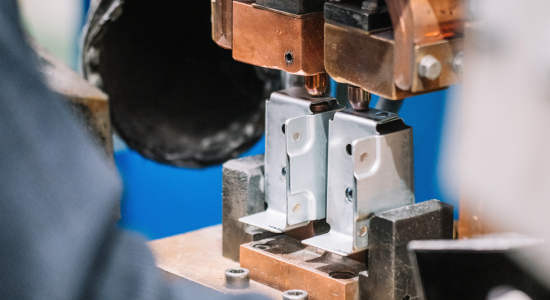

Structural Mounting Parts

- Reason for use: With their drilled holes and various cutouts, these parts can be used to secure complex structures, such as electrical equipment in vehicles or parts of industrial robots, which require high precision.

Chassis or Frame for Industrial Machines

- Reason for use: These parts can serve as the foundation or structural frame for machinery, such as CNC machines, conveyor systems, or robotic arms. Their robust construction provides stability and support for heavy or high-precision equipment.

Material

Aluminum Alloy

Stainless Steel

Quality Control

Our factory ensures strict quality control throughout the sheet metal manufacturing process. From material inspection to final product testing, we utilize advanced equipment and adhere to international standards to guarantee precision, durability, and consistency. Each product undergoes thorough checks for dimensions, surface finish, and structural integrity, ensuring it meets client specifications and industry requirements.

Processing capability

Our factory offers extensive processing capabilities in sheet metal fabrication, including advanced cutting, bending, punching, welding, and forming techniques. We work with a wide range of materials, including stainless steel, aluminum, and carbon steel, and are equipped with state-of-the-art machinery to handle both small and large production runs. Our skilled team ensures precision in every stage of the process, from prototype development to final production, allowing us to meet the unique needs of various industries.

Additional processes

In addition to standard sheet metal fabrication processes, our factory offers a variety of additional services such as powder coating, anodizing, electroplating, laser engraving, and custom surface treatments. These processes enhance the appearance, durability, and corrosion resistance of the finished products, making them suitable for a wide range of applications. Our team ensures that each additional process is executed with precision to meet specific customer requirements and industry standards.