Product Description

Precision manufacturing process that utilizes computer-controlled machines to remove material from a workpiece. This technique is highly versatile and can produce complex shapes, intricate details, and tight tolerances. CNC milling machines use rotating cutting tools to shape the material, which can be metals, plastics, or composites. The process ensures repeatability and high precision, making it ideal for prototypes, custom parts, and high-volume production. CNC milling can perform a variety of tasks, including drilling, boring, and contouring. It is widely used across industries such as aerospace, automotive, and electronics.

Product parameters

| List | Details |

|---|---|

| Product name | Precision Parts CNC Machining |

| Standard | Non-standard Parts |

| Material Capabilities | stainless steel, Aluminum, Brass, Copper, Bronze, Hardened Metals, Precious Metals, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Tolerance | 0.01mm |

| Advantage | Professional Service High Quality |

| Service | OEM ODM Customized |

| Quality | 100% Inspection |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

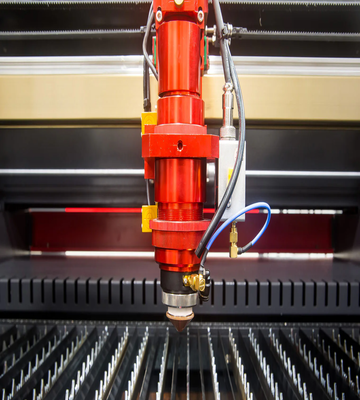

Process Type

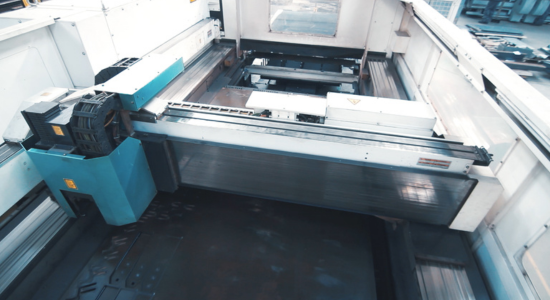

Milling & Drilling

Laser Cutting

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

CNC milling machining ensures the precision and accuracy of each part produced. It involves strict measurement and inspection at various stages of production, using advanced tools like micrometers, calipers, and coordinate measuring machines (CMM). Tolerances and dimensions are verified against design specifications to ensure conformance. Regular calibration of CNC machines is performed to maintain consistent performance. Surface finish, material integrity, and overall part functionality are also thoroughly checked. Any deviations are immediately addressed to maintain high-quality standards and meet customer requirements.

Processing capability

The processing of CNC milling machining involves several key steps to produce precise and complex parts. First, the design or CAD model of the part is created and converted into a CNC-readable program using CAM (Computer-Aided Manufacturing) software. This program specifies the tool paths, cutting speeds, and feed rates required for machining.

Next, the material, typically metal, plastic, or composite, is securely fixed onto the CNC machine bed using clamps or fixtures. The CNC milling machine uses rotating cutting tools to remove material from the workpiece based on the programmed instructions. The process may involve multiple tool changes to perform different operations such as drilling, boring, and contouring.

Additional processes

As the machine executes the program, it continuously monitors tool wear and adjusts settings as necessary to maintain precision. After the machining process, parts undergo inspection to verify dimensional accuracy and surface finish. If needed, secondary operations like deburring or polishing are performed to meet the required specifications. Throughout the process, strict quality control ensures the final part meets all design requirements and tolerances.