Product Description

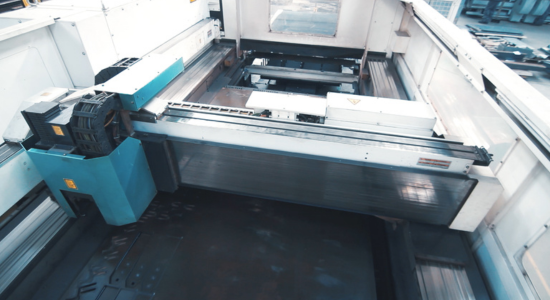

The 5Axis Custom OEM CNC machine offers precision engineering and advanced capabilities for complex, high-accuracy parts manufacturing. With five axes of motion, it ensures seamless multi-dimensional cutting, enabling intricate geometries and smooth finishes. This CNC system is tailored for custom OEM needs, providing versatile solutions for industries such as aerospace, automotive, and medical. It supports various materials, ensuring flexibility in production. The user-friendly interface and robust build make it ideal for both large-scale production and one-off custom projects. Optimize your manufacturing process with the 5Axis Custom OEM CNC for exceptional quality and efficiency.

Product parameters

| List | Details |

|---|---|

| Brand Name | Cnc Machining Parts,CNC Aluminum Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Material | Aluminum, copper, brass, stainless steel, iron, alloy, zinc etc. |

| Process | CNC Machining |

| Surface treatment | Anodizing,Galvanized,laser engraving,polishing,Powder coating, |

| Service | OEM ODM CNC Drilling Milling Machining Service |

| Equipment | CNC Machining Centres |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Milling & Drilling

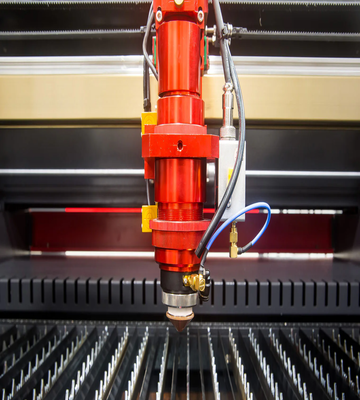

Laser Cutting

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The QC process for the 5Axis Custom OEM CNC ensures top-tier quality and precision throughout production. Each component undergoes rigorous inspection, including dimensional accuracy checks using advanced measuring tools. The machine's performance is tested under load conditions to verify stability and repeatability. Material quality is also scrutinized, ensuring durability and compliance with industry standards. Post-machining, parts are thoroughly inspected for surface finish and geometric integrity. Additionally, automated quality control systems track every stage of production to guarantee consistency and reduce errors, ensuring reliable and high-quality outputs for custom OEM projects.

Processing capability

The 5Axis Custom OEM CNC is designed to handle a wide range of complex machining tasks, offering exceptional processing capabilities for high-precision parts. It features simultaneous movement across five axes, enabling intricate geometries and precise contours that traditional 3-axis machines cannot achieve. This allows for the production of complex, multi-dimensional parts without the need for multiple setups, significantly reducing production time.

The machine supports a variety of materials, including metals (aluminum, steel, titanium), plastics, and composites, making it versatile for industries such as aerospace, automotive, and medical device manufacturing. It is capable of milling, drilling, and tapping, as well as performing intricate contouring, threading, and engraving operations.

Additional processes

Advanced toolpath programming ensures optimal cutting strategies, while the high-speed spindle and robust machine structure provide both fast processing and fine surface finishes. The 5Axis CNC also excels in creating parts with tight tolerances, often achieving accuracy levels in the micron range. Its ability to perform under high-load conditions without compromising precision makes it suitable for both prototype and large-scale production runs.

Additionally, the machine’s automation and integration with CAD/CAM software allow for seamless design-to-production workflows, reducing human error and increasing efficiency. This makes the 5Axis Custom OEM CNC an ideal solution for companies seeking precision, speed, and flexibility in their manufacturing processes.