Product Description

PH series servos highly integrate the three major components of reducer, motor and drive to form an ultra-small integrated servo module. The joints adopt bus design and hollow wiring, which greatly simplifies the system structure. It adopts high-precision double magnetic design and optional brake to meet various harsh working conditions.

Product parameters

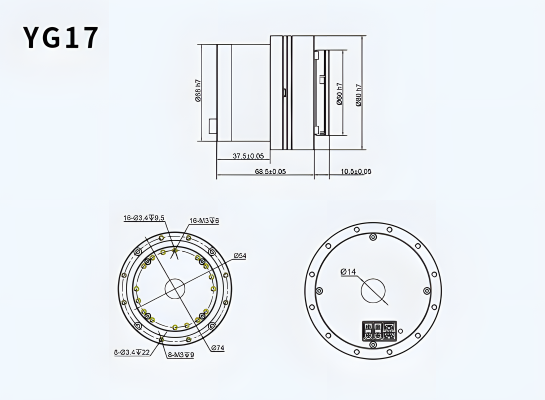

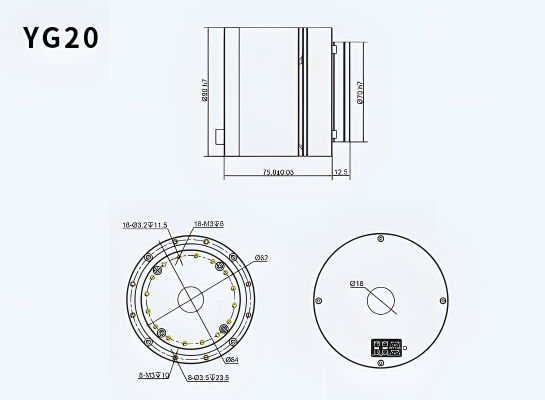

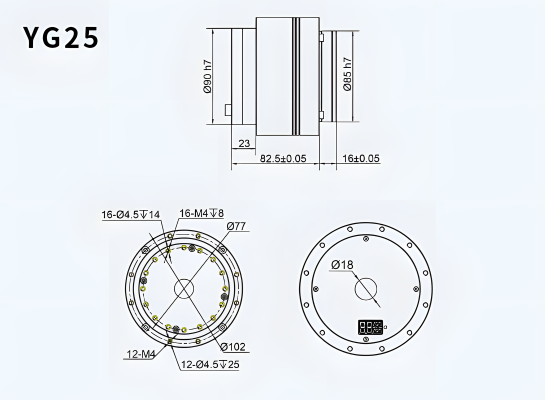

| Model | YG08 | YG11 | YG14 | YG17 | YG20 | YG25 | ||||||

| Motor type | Inner rotor torque motor | |||||||||||

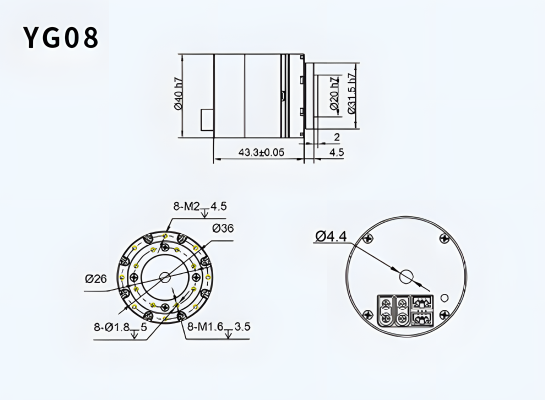

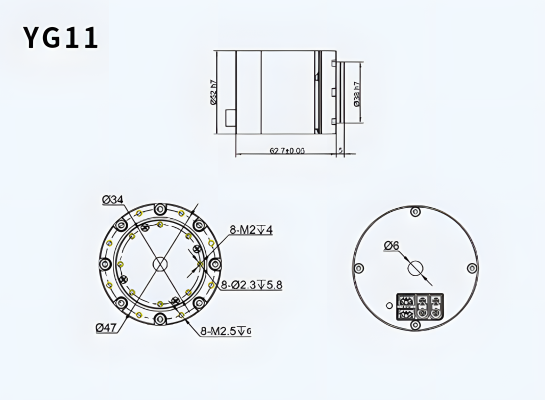

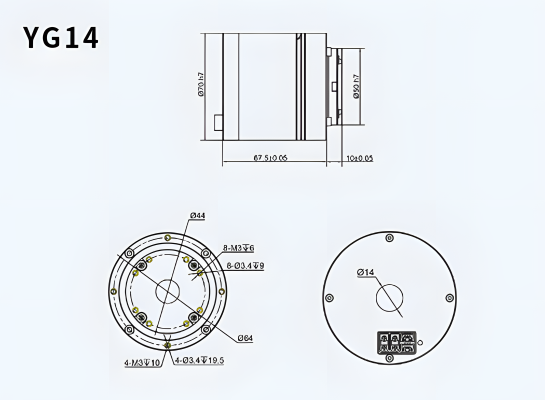

| Diameter | 40mm | 52mm | 70mm | 80mm | 90mm | 110mm | ||||||

| Hollow inner diameter | 4.6mm | 6mm | 10.8mm | 10.8mm | 13mm | 13mm | ||||||

| Weight | 188g | 495g | 1108g | 1350g | 1991g | 3098g | ||||||

| Backlash | 15arcsec | |||||||||||

| Noise | <70db | |||||||||||

| Temperature range | -20~80℃ | |||||||||||

| Operating voltage | 24~36v | 24~48v | ||||||||||

| Rated power | 36w | 120w | 120w | 200w | 250w | 500w | ||||||

| Speed ratio | 51 | 101 | 51 | 101 | 51 | 101 | 51 | 101 | 81 | 121 | 81 | 121 |

| Rated speed | 60rpm | 30rpm | 60rpm | 30rpm | 60rpm | 30rpm | 60rpm | 30rpm | 38rpm | 25rpm | 38rpm | 25rpm |

| Rated torque | 1.0nm | 1.6nm | 6.6nm | 8.6nm | 18nm | 22nm | 30nm | 38nm | 52nm | 78nm | 96nm | 144nm |

| Peak torque | 2.2nm | 3.5nm | 21nm | 24nm | 30nm | 38nm | 52nm | 66nm | 104nm | 156nm | 206nm | 220nm |

| Encoder accuracy | 19bit | |||||||||||

| Encoder type | Double magnetic braid | |||||||||||

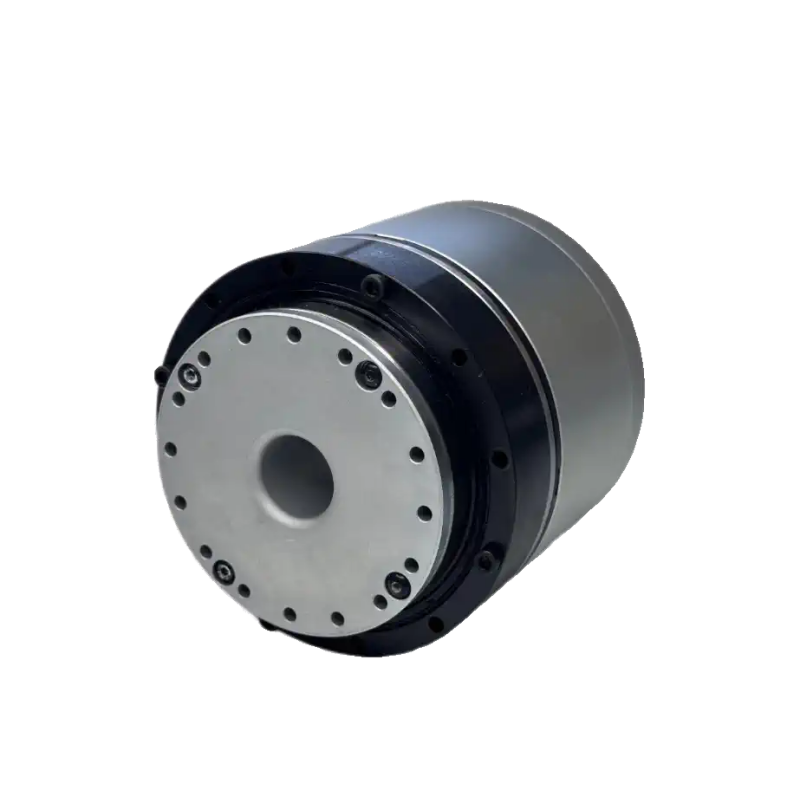

Product Display

- Full hardware FOC drive design 20khz high-speed closed-loop calculation

- Ultra-thin power-off brake

- High-precision harmonic reducer with low noise and high precision

- High-precision double magnetic encoder 19bit+19bit

- High-density torque motor with low cogging torque

- Full series of hollow design with the smallest hollow module outer diameter of 40mm

Size & Interface

Application Cases

The servo module adopts a hollow design, which is particularly suitable for the six-axis collaborative robot arm. The high-speed closed-loop cycle of the module can flexibly control the rigidity and precision of the robot arm, providing a high-performance body for the host computer. The robot joints with different loads can be freely combined, and the body and software technical support are provided, so that customers can quickly build their own robot system.