Product Description

This series of electromagnetic power-off brake is a type of electromagnetically drawn, power-off friction brake. A new YEJ series electromagnetic braking three-phase asynchronous motor is mainly generated by matching with Y series motors. Widely used in metallurgy, construction, chemical industry, food, machine tools, packaging and other machinery, to achieve rapid stop and accurate positioning, can be used in the power off safety (hazard) braking and other occasions.

Product specifications

| Item \ Model | SDZ1-02 | SDZ1-04 | SDZ1-08 | SDZ1-15 | SDZ1-30 | SDZ1-40 | SDZ1-80 | SDZ1-150 |

|---|---|---|---|---|---|---|---|---|

| Matching motor frame number | 63 | 71 | 80 | 90 | 100 | 112 | 132 | 160 |

| Rated braking torque Me(N.m) | 2 | 4 | 7.5 | 15 | 30 | 40 | 75 | 150 |

| Rated voltage DC(V) | 99 | 170 | ||||||

| Rated power P20°C(W) | 25 | 30 | 40 | 50 | 65 | 70 | 95 | 110 |

| Braking time (ms) | 150 | 180 | 200 | 250 | 350 | |||

| Maximum working air gap (mm) | 0.6 | 0.8 | 1 | 1.2 | ||||

| Maximum allowable relative speed (rpm) | 3000 | |||||||

Product parameters

| Model \ Size | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | L | L1 | L2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SDZ1-02 | 60 | 39 | 72 | 86 | 89 | 12 | 25 | 36 | 49 | 38 | 18 | 2 |

| SDZ1-04 | 77 | 53 | 90 | 103 | 108 | 15 | 28 | 42 | 56 | 44 | 20 | 2 |

| SDZ1-08 | 92 | 65 | 105 | 119 | 123 | 20 | 35 | 50 | 62 | 53 | 20 | 3 |

| SDZ1-15 | 97 | 65 | 114 | 128.5 | 138 | 24.5 | 40 | 60 | 75 | 54.5 | 25 | 3.5 |

| SDZ1-30 | 117 | 80 | 133 | 148.5 | 156 | 30 | 50 | 70 | 85 | 56 | 30 | 3.5 |

| SDZ1-40 | 130 | 90 | 150 | 168.5 | 176 | 30 | 50 | 75 | 90 | 57.5 | 30 | 3.5 |

| SDZ1-80 | 150 | 104 | 170 | 188.5 | 196 | 40 | 60 | 88 | 105 | 68 | 30 | 3.5 |

| SD1-150 | 180 | 120 | 202 | 222 | 228 | 45 | 60 | 101 | 120 | 81 | 35 | 4 |

| Model \ Size | L3 | L4 | L5 | L6 | H1 | H2 | M | N | d | Φ | h | b | δ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SDZ1-02 | 7 | 24 | 52 | 6 | 52.5 | 40 | 3-M4 | 3-M4 | 10 | 12 | 13.8 | 4 | 0.2 |

| SDZ1-04 | 9 | 24 | 60 | 6 | 60 | 45.5 | 3-M5 | 3-M5 | 10 | 14.8 | 16.2 | 5 | 0.2 |

| SDZ1-08 | 9 | 26.5 | 71 | 6 | 75 | 55 | 3-M5 | 3-M5 | 10 | 19.8 | 22.6 | 6 | 0.3 |

| SDZ1-15 | 10 | 28.5 | 78 | 7 | 78 | 67 | 3-M6 | 3-M6 | 10 | 24.8 | 28.1 | 8 | 0.4 |

| SDZ1-30 | 12 | 28.5 | 77 | 8 | 90 | 67 | 3-M6 | 3-M6 | 10 | 29.5 | 32.8 | 8 | 0.4 |

| SDZ1-40 | 12 | 33 | 78.5 | 8 | 100 | 67 | 3-M8 | 3-M8 | 10 | 29.5 | 32.8 | 8 | 0.5 |

| SDZ1-80 | 14 | 39 | 94 | 10 | 113 | 67 | 3-M8 | 3-M8 | 12 | 39.5 | 42.8 | 12 | 0.5 |

| SD1-150 | 15 | 46 | 110 | 14 | 132 | 148 | 4-M10 | 4-M10 | 20.5 | 44.5 | 47.8 | 12 | 0.6 |

Working principle

This is usually done using the principle of friction. When the brake signal is sent, the brake part (such as the brake block or brake shoe) is in close contact with the rotating part (such as the motor shaft, the drive shaft, etc.) under a certain force. Through friction, the movement of rotating parts is hindered, thus stopping the operation of the equipment. The friction materials are generally wear-resistant and high-temperature resistant materials to ensure the reliability and durability of braking.

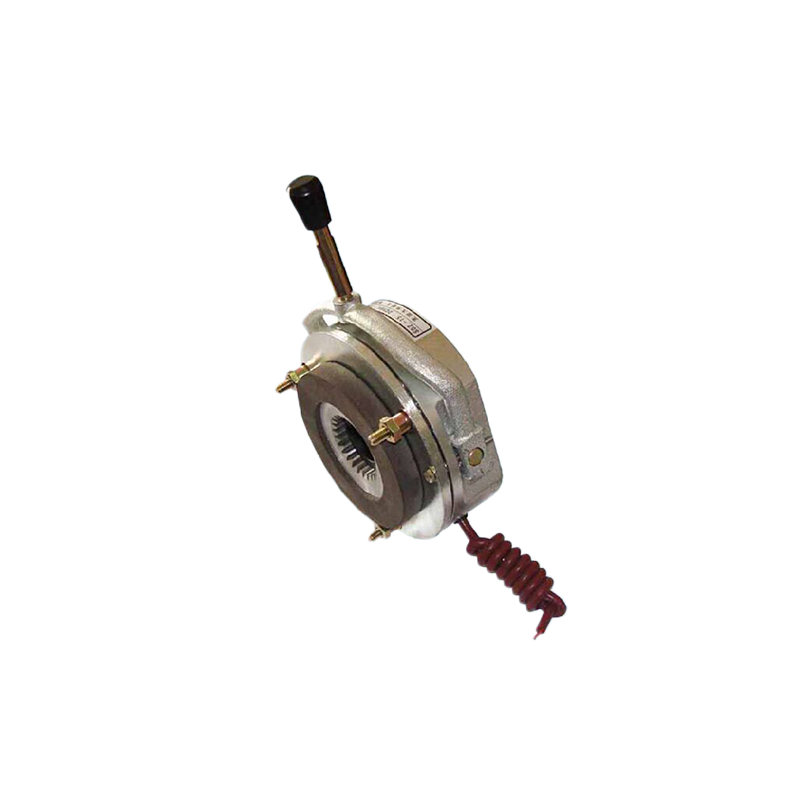

Product Display

High reliability

The ability to brake equipment in a timely and effective manner when needed, reducing the risk of safety accidents and equipment damage caused by brake failure. For example, in lifting equipment, if the brake fails, heavy objects may fall out of control, and the SDZ1-08 brake can avoid this situation with its reliable structural design and performance.

Precise control

More accurate braking control can be achieved according to the requirements of the equipment. For example, on some automatic production line equipment that requires precise positioning, it can brake in accordance with the preset position and time to ensure the accuracy of the motion of the equipment.

Strong adaptability

Can adapt to different working environment and working conditions. It can work normally under certain temperature, humidity and dust environment. For example, in the factory floor environment, even if there is more dust and a certain temperature change around, it will not easily affect its braking performance.

Quality Control

Electromagnetic brake quality control covers multiple links:

When purchasing raw materials, the key materials such as enameled wire, friction sheet and iron core are strictly screened and tested to ensure that their electrical, friction and magnetic properties meet the standards. In the production and processing, high-precision equipment is used to control the machining accuracy of parts, and the assembly quality is guaranteed through standardized assembly process and strict testing, including static suction, brake clearance adjustment, and simulated brake test. The finished products need comprehensive quality inspection and durability testing, and comply with international and domestic standards to obtain relevant certifications, from the source to the finished product comprehensive control, to ensure high quality, high reliability and high performance of products, to meet the braking needs of various fields.

Application Cases

Lifting machinery: widely used in lifting, running and amplitude changing mechanisms of cranes. When the crane lifts heavy objects and needs to stay in the air or stop running, the SDZ1-08 brake can ensure the safe rest of the heavy objects and prevent the accidental fall of heavy objects.

Conveying equipment: such as belt conveyor, chain conveyor, etc. When the equipment needs to stop conveying materials or perform emergency braking, it can quickly and effectively stop the conveying equipment to avoid material accumulation or overflow.

Machine tool equipment: It plays a role in the braking of the spindle and feed shaft of the machine tool. For example, after the CNC lathe completes a part, it is necessary to accurately stop the rotation of the spindle, and the SDZ1-08 brake can provide high-precision braking to ensure the processing accuracy.

Company Introduction

Wuhu Dazhong Electromechanical Manufacturing Co., Ltd. is located in Wuhu high-tech Industrial Development Zone auto parts road, the traffic is very convenient, covers a total area of 18578.42 square meters, construction area of 11118.72 square meters, the company was founded in 1998, to produce, research and development of new electromagnetic brakes, clutches and related products. In line with the quality policy of "quality first, customer first, forge ahead and strive for innovation", the company constantly strengthens its scientific research and design capabilities, and strives to absorb advanced technology and experience at home and abroad. In order to strengthen quality management, a complete quality control system has been established from process design, raw material purchase to manufacturing, and the quality management system has passed ISO9001:2000 certification; The company has developed rapidly, and was recognized as a provincial private science and technology enterprise and provincial high-tech enterprise by Anhui Province in 2007.

The single-piece electromagnetic clutch and brake, power loss brake, micro brake and other products produced by our company are widely used in printing, paper, packaging, medical, textile, construction, motor, food, lifting machinery and other automatic control fields, products are sold at home and abroad.

Continuous development of new products, so that we can better meet the needs of users, excellent quality and service so that we can have a broader market space. "Letter for the enterprise, honesty is the root of life", we are willing to cooperate with friends from all walks of life to create a better tomorrow.

Service

Pre-sale professional consultation

We have an experienced and skilled professional consulting team, who deeply understand every technical detail and application scenario of the product. Whether you are in contact with the product for the first time, or are hesitant to select a specific industrial equipment, our consulting experts will patiently listen to your needs and give you detailed information about the performance characteristics, technical parameters, scope of application and other key information. Through in-depth communication, we can help you accurately evaluate whether the product meets your actual application needs, provide you with professional and personalized selection recommendations, and ensure that you make the most informed purchasing decisions.

Close follow-up in the sale

Once you have confirmed your purchase order, our service team will quickly start the in-sale follow-up process. We will maintain close communication with you and keep you informed of important information such as order processing progress, production schedule and estimated delivery time. In the production process, we strictly control the quality and delivery of each link, to ensure that products are delivered to your hands on time and in good quality. At the same time, we will also assist you to deal with the various documents and procedures related to the order, such as contract signing, invoice issuance, logistics and transportation arrangements, so that your procurement process is convenient and smooth, without any worries.

After-sales timely response

We know the importance of product after-sales support, so we have established an efficient and fast after-sales response mechanism. In the process of your use of the product, no matter you encounter any technical problems or failures, just call our after-sales service hotline, our professional after-sales engineers will get in touch with you in the first time. Through telephone communication, remote video guidance services, etc., quickly diagnose problems for you and provide effective solutions. For situations requiring on-site repair, our after-sales team will bring professional tools and spare parts to the site as quickly as possible to minimize equipment downtime and reduce the impact on your production operations.

Value-added service expansion

In order to provide customers with more comprehensive value support, we also continue to expand the field of value-added services. For example, we provide customers with customized braking system solutions, according to the customer's specific industrial equipment and process requirements, optimized design and integration of products, to achieve a perfect match and collaboration with customer equipment. In addition, we also provide product upgrade services, when there are new technical improvements or function upgrades, timely notify customers and assist customers to upgrade products, so that customers always stay in the forefront of industry technology, enhance market competitiveness.