Product Description

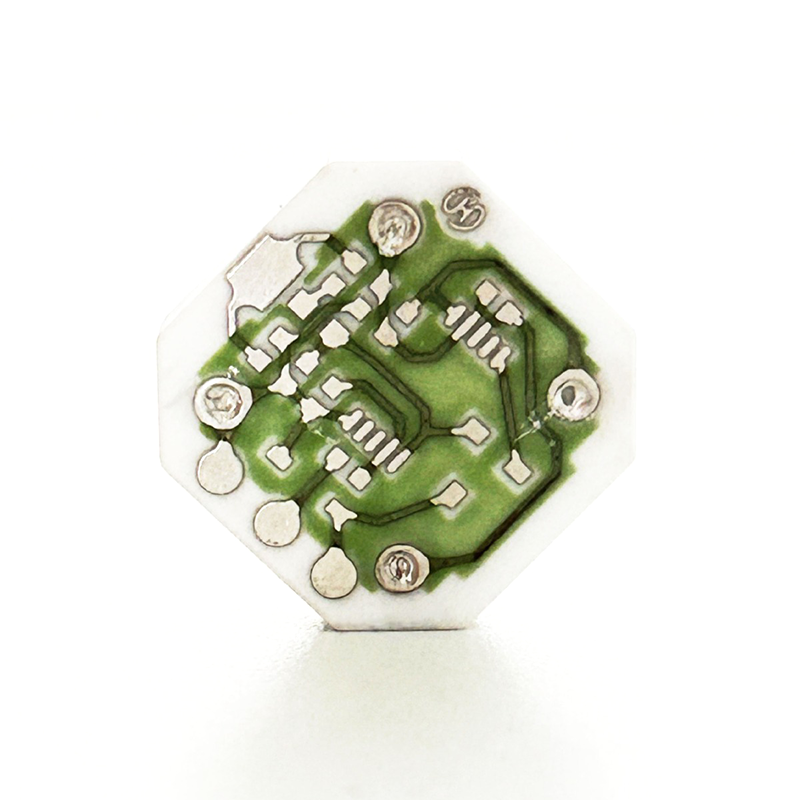

When the ceramic capacitor pressure sensitive element is subjected to pressure, the elastic diaphragm bends and deforms, and the capacitance changes accordingly. Within the measuring range, the pressure is linearly proportional to the capacitance. The capacitance change is then amplified, calibrated, and nonlinearly fitted through the conditioning chip to obtain an analog voltage output or digital signal that is linearly proportional to the pressure change.

Product parameters

| Series Name | D21MV、D18MV |

|---|---|

| Type | Ceramic capacitor pressure sensor module |

| Test Pressure Type | Gauge pressure, sealed pressure, absolute pressure |

| Dimensions (Diameter x Height) | φ 21x(4.25~4.85)mm 、φ18x(3.35~3.95)mm |

| Supply Voltage | 5.0V ±10% DC |

| Operating Current | <10 mA |

| Output Voltage | 0.5-4.5V DC |

| Over Voltage | < 12V DC |

| Operating Temperature | -40 ℃~125℃ |

| Storage Temperature | -40℃~150 ℃ |

| Non-Linearity | 0.25% FS Max |

| Hysteresis & Repeatability | 0.25% FS Max |

| Output accuracy | 0.5-4.5V DC |

| Response time | < 10 mS |

| Long-term stability | Zero point @ 25℃: <0.25%FS0 (no time accumulation) |

| Working life | > 5 million pressure cycles @ 2-5Hz, 0~ full scale pressure~0, 15-35℃ |

| Working medium | Oil, water, gas, refrigerant, coolant, chemical solvent, detergent, etc. |

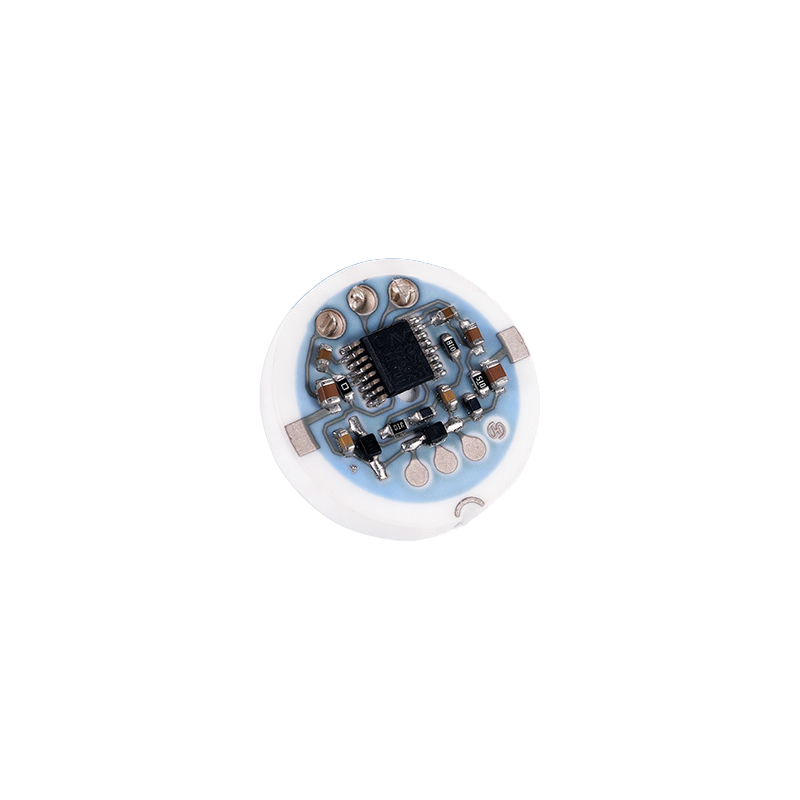

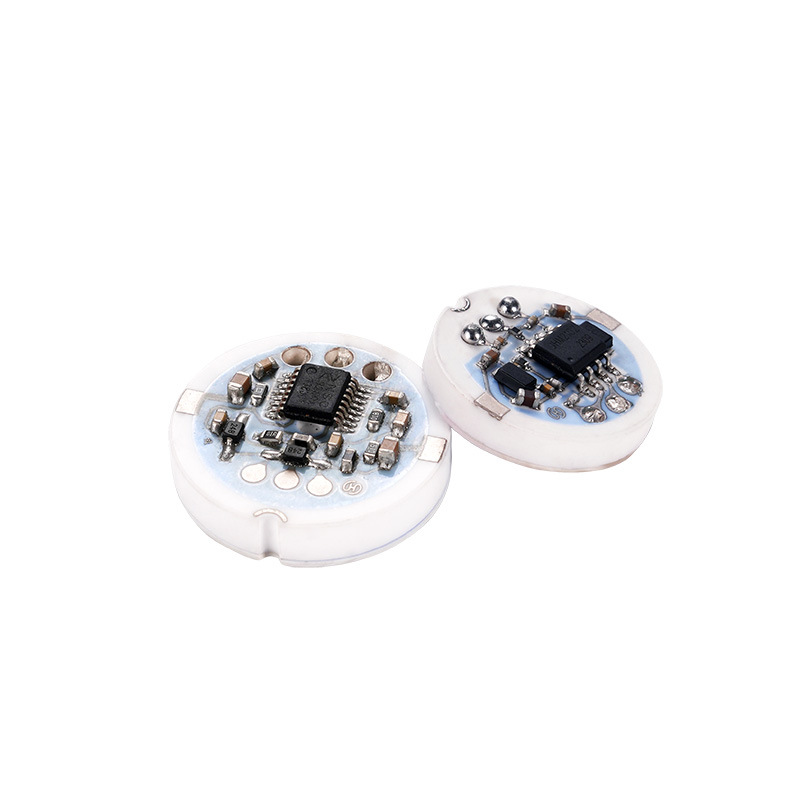

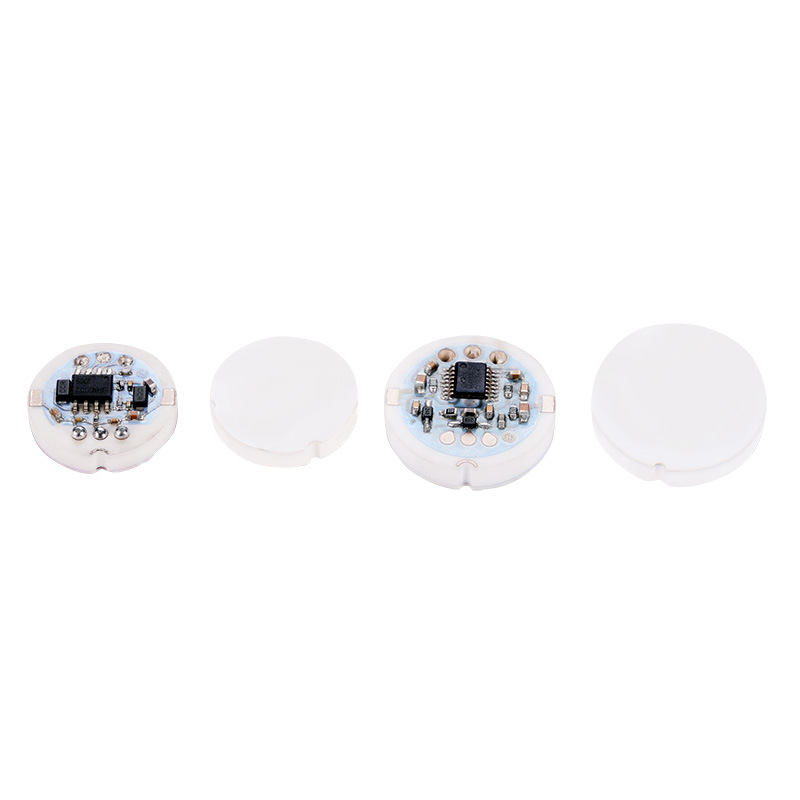

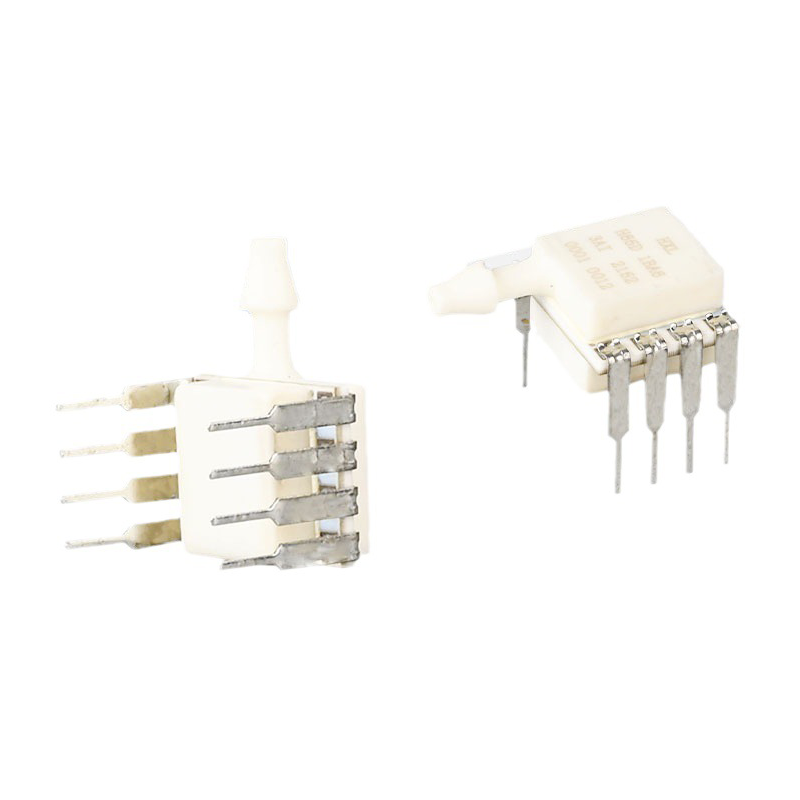

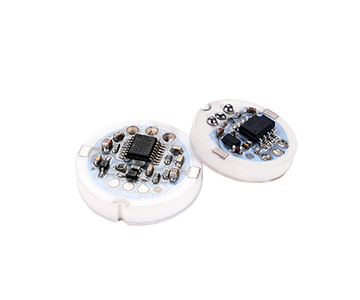

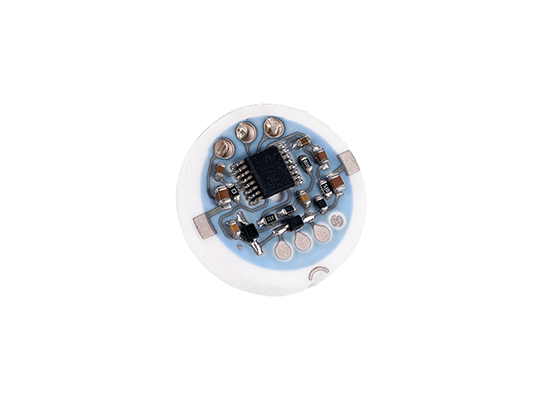

Product Display

- Integrated integration, high product stability

- Supports customization of multiple output signals such as current, voltage, IIC, etc.

- Easy and convenient to use

- With excellent EMC protection and reverse polarity protection

Excellent corrosion and wear resistance

Various styles and customizable

High sensitivity, high precision, high stability

Small size, easy to package

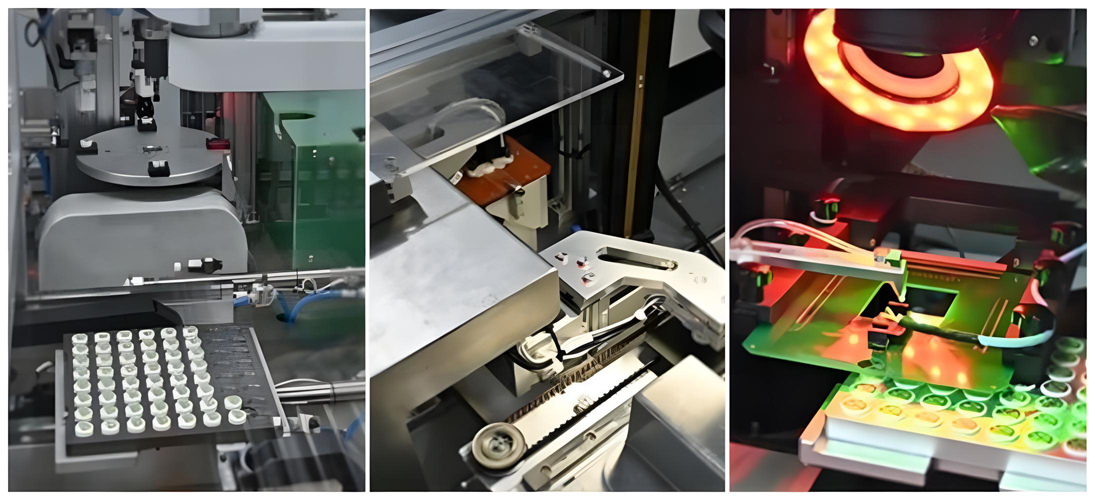

Quality Control

Huaxinlian Technology has a number of core patented technologies. Its products adopt the industry's most advanced design concepts and process routes. Various performance indicators have reached the international leading level. It is equipped with advanced automatic production lines and produces more than 5 million piezoresistive cores and 2 million modules annually. It is the largest ceramic pressure sensor manufacturer in China.

The company has a dust-free workshop of more than 4,000 square meters, equipped with a fully automated production line, which can produce more than 20,000 ceramic cores per day and more than 7 million per year. With strong R&D capabilities and rigorous production processes, the high quality and reliability of the products are ensured. So far, the company has obtained more than 50 patents and successfully passed ISO9001 and IATF16949 certifications. Huaxinlian Technology is committed to innovation, providing global customers with excellent innovative products and high-quality technical services, and jointly promoting the rapid development of the sensor industry.

Application Cases

In industrial automation, D21MV/D18MV ceramic capacitor pressure sensor modules accurately monitor the pressure of hydraulic and pneumatic equipment to ensure efficient operation of production lines; in medical equipment, such as ventilators and blood pressure monitors, they accurately sense pressure changes to assist in diagnosis and treatment; in the aerospace field, they can reliably cope with extreme environments and ensure the safe and stable operation of aircraft hydraulic, fuel and other systems; in smart homes, they can assist in the intelligent control of air conditioners, gas water heaters, air purifiers, etc. With its excellent performance, it is widely used in many industries and has become an indispensable precision sensing core component in many key application scenarios.

Service

- Source factory: As the source factory, we control the entire production process, from high-quality raw material procurement to fine processing and manufacturing, to ensure that the product quality is excellent and the cost performance is super high.

- Support customization: According to your special needs, whether it is unique size specifications or personalized performance requirements, we can customize and create a ceramic concave diaphragm pressure module exclusive to you.

- Two-year warranty quality assurance: The two-year warranty period demonstrates our high confidence in product quality. If there are any quality problems during this period, we will respond quickly and handle them properly to relieve you of your worries.

- Professional engineer consultation without worries: The professional engineer team relies on deep knowledge and rich experience to answer your questions at any time, providing a full range of consulting services from product technical details to application solution planning, so that you have no worries.