Product Description

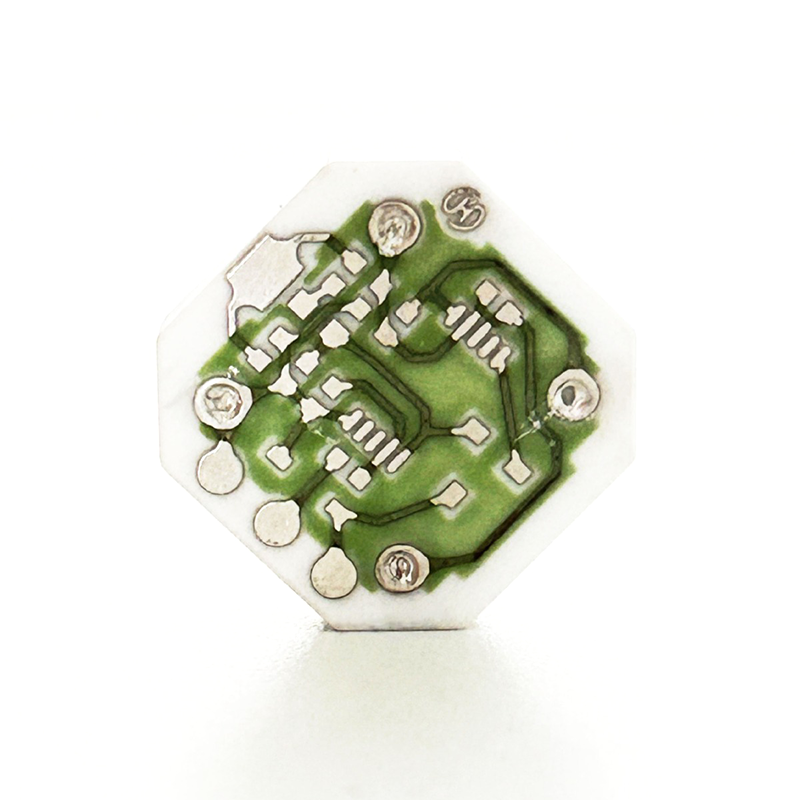

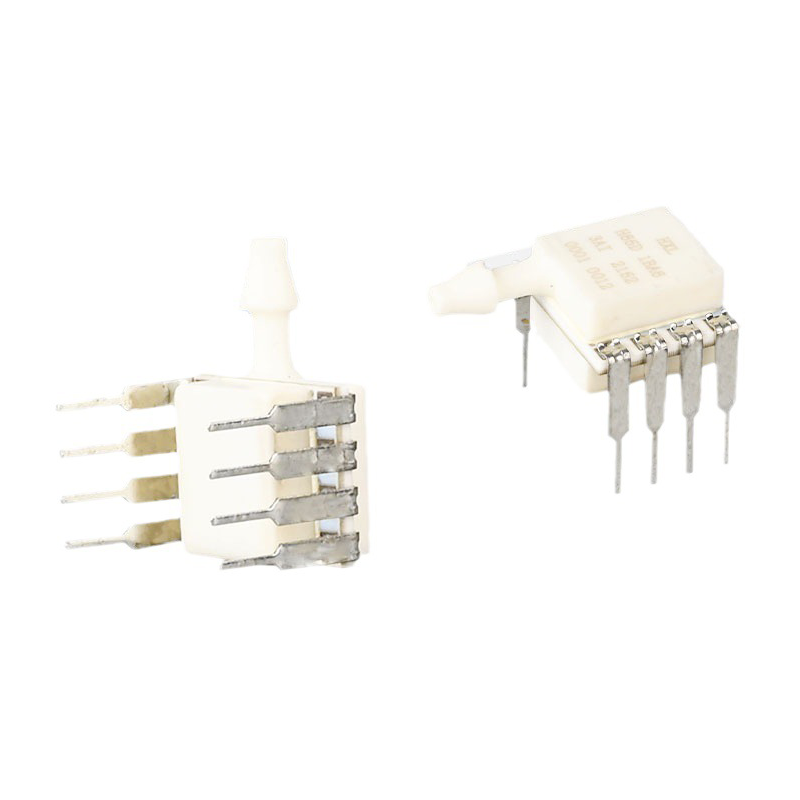

The CPS18635MI and CPS18350MI concave film ceramic piezoresistive sensor current output modules use a refined alumina ceramic base, combined with highly stable sensitive materials, and are refined through processes such as silk screen printing, high-temperature sintering, and laser resistance trimming.

The overall dimensions of CPS18635MI are φ18*6.35mm, and the overall dimensions of CPS18350MI are φ18*3.50mm. Their unique circuit design significantly improves the reliability of the product. The temperature compensation circuit is integrated inside the sensitive element and has been laser-engraved, so that the internal bridge temperature drift signal is close to zero (≤0.02% FS/℃) within the normal use range (-20℃ to 85℃), which greatly reduces Temperature compensation calibration work required during the production of pressure sensors.

Ceramics have good thermal stability and creep resistance, operate in a temperature range of -40°C to 150°C, and exhibit excellent long-term stability.

The corrosion resistance of ceramics gives it significant advantages in the fields of refrigeration, chemical industry, medicine and environmental protection, and gradually replaces common diffused silicon pressure sensors.

Temperature-compensated ceramic piezoresistive sensor cores have become the first choice for pressure sensing elements in IoT applications due to their extremely high cost-effectiveness, and are widely used in pressure measurement of air, water, oil and other media. They are widely used in automobiles, air compressors, fire hoses, industry and home appliances, etc. Our company can customize pressure sensitive cores of various shapes and sizes according to customer needs.

Product parameters

| Parameter Name | Parameter value |

|---|---|

| Series Name | CPS 18635MI/CPS18350MI |

| Type | Current output module of concave film ceramic piezoresistive sensor |

| Test Pressure Type | Gauge pressure |

| Dimensions (Diameter x Height) | φ18x6.35mm、φ18x3.50mm |

| Supply Voltage | 12-30V DC |

| Operating Current | 4-20 mA |

| Operating Temperature | -40 ℃~125℃ |

| Storage Temperature | -40 ℃~150℃ |

| Non-Linearity | 0.25% FS Max |

| Hysteresis & Repeatability | 0.25% FS Max |

| Response time | < 2mS |

| Insulation resistance | >100MΩ |

| Long-term stability | Zero point @25℃: <0.25%FS0 (no time accumulation) |

| Working life | >2 million pressure cycles @2-5Hz, 0~full scale pressure~0,15~35℃ |

| Working medium | Oil, water, gas, refrigerant, coolant, chemical solvent, detergent, etc. |

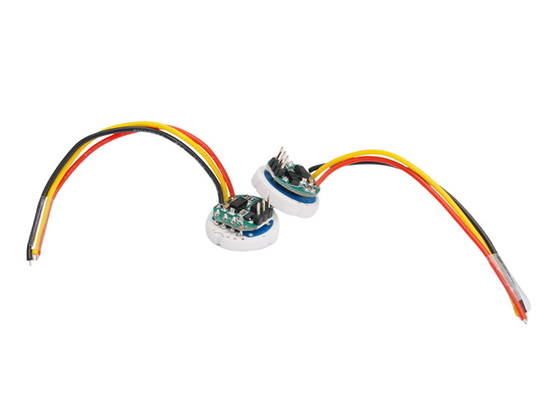

Product Display

- The integrated integrated design makes the internal structure of the product compact and efficient, and each component cooperates seamlessly to effectively resist fluctuations and interference from the external environment. The stability is significantly improved, and the continuous and stable operation time is far longer than that of similar products.

- It supports the customization of various output signals such as current, voltage, IIC, etc., meets the diverse needs for signal type and accuracy in different fields such as industrial automation, smart home appliances, and medical equipment, and achieves precise adaptation to various systems.

Anti-corrosion performance: Special materials are corrosion-resistant and are not damaged by acid and alkali erosion.

Anti-wear performance: The surface is strong, wear-resistant and damage-resistant, and it remains as good as new after long-term use.

High sensitivity: It can detect even tiny pressures and accurately sense slight changes.

High precision: The error of fine measurement is very small, and the data is accurate and reliable.

High stability: It is as stable as Mount Tai in complex environments and has constant continuous working performance.

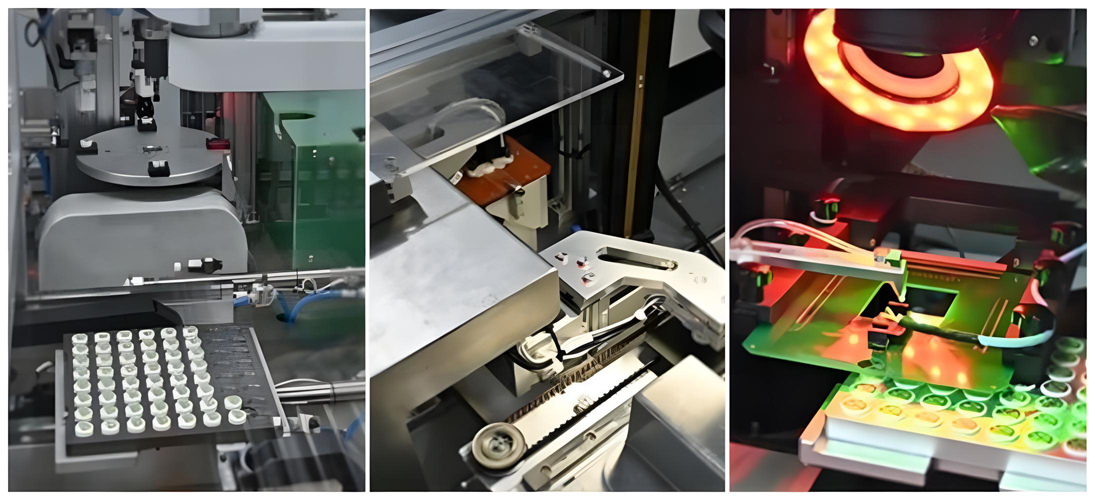

Quality Control

The company has a dust-free workshop of more than 4,000 square meters, equipped with a fully automated production line, which can produce more than 20,000 ceramic cores per day and more than 7 million per year. With strong R&D capabilities and rigorous production processes, the high quality and reliability of the products are ensured. So far, the company has obtained more than 50 patents and successfully passed ISO9001 and IATF16949 certifications. Huaxinlian Technology is committed to innovation, providing global customers with excellent innovative products and high-quality technical services, and jointly promoting the rapid development of the sensor industry.

Application Cases

- The ceramic piezoresistive sensor current output module, with its high sensitivity, is very useful in the field of industrial manufacturing. It accurately monitors the pressure changes of mechanical equipment and provides key data for automated production process control through stable current output, effectively ensuring the efficient and stable operation of the production line.

- In the field of smart home, the ceramic piezoresistive current output sensor module is a powerful assistant for smart life. For example, in a smart air purifier, it can accurately sense changes in air pressure and convert them into stable current output, thereby intelligently controlling the fan speed, keeping the indoor air fresh and clean at all times, and improving the comfort of the home environment.

- For aerospace, this sensor module is the guardian of flight safety. It is installed in the aircraft's air pressure control system. With its high sensitivity and high precision, it can quickly capture subtle differences in air pressure in complex and changeable high-altitude environments. Through reliable current signal transmission, it ensures the stability of cabin air pressure and the normal operation of various pneumatic equipment during flight, helping the aerospace industry to reach new heights.

Service

- Professional engineers provide worry-free consultation: With deep knowledge and rich experience, our professional engineering team is ready to answer your questions at any time, providing a full range of consulting services from product technical details to application plan planning, so that you will not have any trouble.

- Source factory: As the source factory, we control the entire production process, from high-quality raw material procurement to fine processing and manufacturing, to ensure that the product quality is excellent and the cost performance is super high.

- Support customization: According to your special needs, whether it is unique size specifications or personalized performance requirements, we can customize and create a ceramic concave membrane pressure module exclusive to you.