Product Description

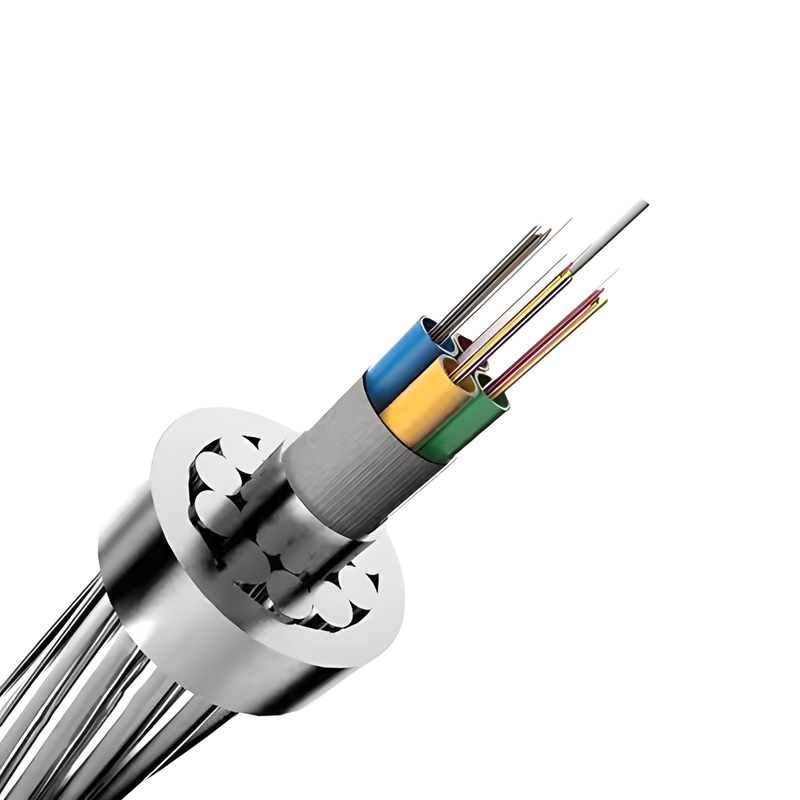

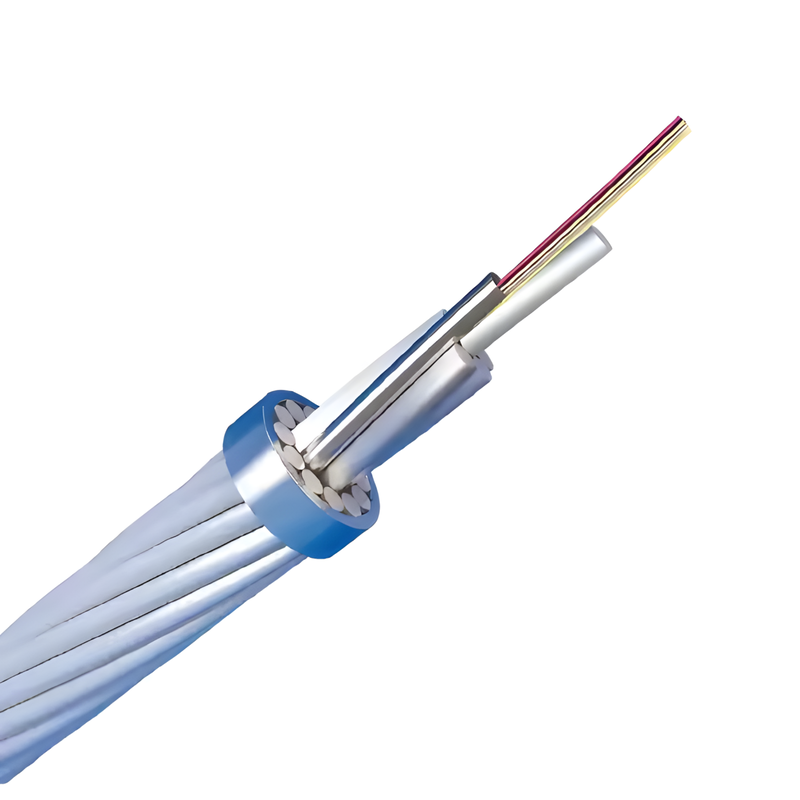

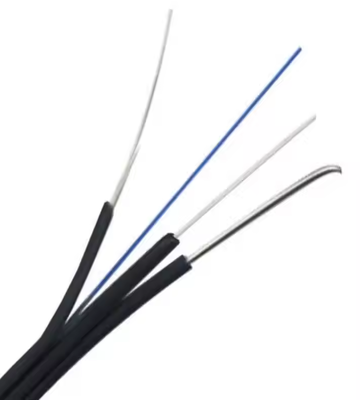

An Optical Fibre Cable is designed for high-speed data transmission using light signals, providing faster and more reliable communication compared to traditional copper cables. It consists of a core made of glass or plastic fibers that transmit light signals, surrounded by an insulating layer and protective coating. These cables offer high bandwidth, low signal loss, and immunity to electromagnetic interference, making them ideal for long-distance and high-performance applications. Optical fibre cables are commonly used in telecommunications, internet connections, data centers, and other industries requiring fast and secure data transfer. They are available in both single-mode and multi-mode configurations, depending on the distance and speed requirements. Optical fibre cables are known for their durability and ability to handle high-frequency transmissions over vast distances.

Product parameters

| List | Details |

|---|---|

| Product name | Optical Fibre Cable |

| Type | Outdoor Fiber Optic Cable |

| Fiber Type | G.652D |

| Fiber count | 6-144 Cores |

| Jacket | PE |

| Cable Diameter | 8.0 mm-16.6 mm |

| Packing | 2-4km/wooden Drum |

| Application | Telecom Comunication |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Cable wire

Optical fiber wire

Bare wire

Material

Bare copper

PVC PE

Quality Control

The QC (Quality Control) of Optical Fibre Cables ensures they meet rigorous standards for performance and reliability. Each cable undergoes visual inspection to detect defects such as surface cracks or improper coatings. Attenuation tests are performed to measure signal loss and ensure the cable meets transmission standards. Tensile strength and bending tests are conducted to ensure the cable can withstand mechanical stress without compromising performance. The core alignment and cladding quality are checked for consistency and precision. Finally, cables are tested for fiber continuity and optical performance before they are packaged and shipped.

Processing capability

The processing capability of Optical Fibre Cables involves advanced manufacturing techniques to ensure high-quality performance, durability, and reliability. The process begins with the production of the fibre core, where glass or plastic fibres are drawn from raw materials in a controlled environment to achieve the desired diameter and uniformity. Cladding is then applied around the core to create total internal reflection, ensuring efficient light transmission.

Coating and curing processes follow, where a protective polymer coating is applied to the fibre to prevent damage from moisture and physical stress. This coating is then cured using ultraviolet light to harden it and increase durability. The fibres are bundled together and arranged in specific configurations, depending on the cable design—single-mode or multi-mode.

Additional processes

The cable construction involves the application of additional layers, such as strengthening materials like aramid yarn or fiberglass for mechanical protection, and outer jacketing made from materials like PVC, LSZH (Low Smoke Zero Halogen), or polyethylene for environmental protection.

After construction, the cables undergo testing to check for optical performance, such as attenuation, fiber continuity, and signal loss. Tensile strength and bend radius testing ensure the cables can withstand mechanical stresses without performance degradation. Finally, packaging is done to ensure the cables are securely coiled and ready for shipment, meeting all quality and safety standards.

This comprehensive process guarantees that optical fibre cables provide fast, reliable, and secure data transmission over long distances.