Product Description

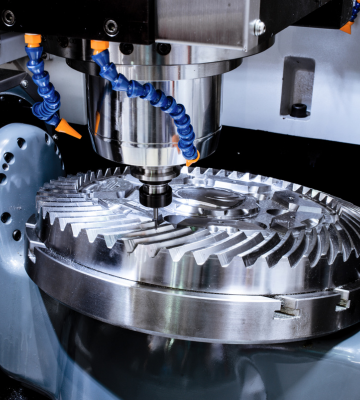

PrecisionCast CNC specializes in producing high-quality stainless steel parts using advanced casting and machining techniques. Our products deliver exceptional durability, precision, and reliability, making them suitable for industries such as automotive, aerospace, and manufacturing. Designed to meet the highest standards, we provide versatile solutions tailored to diverse industrial needs.

Product parameters

| Product Type | CNC precision machining accessories, CNC lathe machining |

| Our Services | CNC machining, stamping, die casting, casting, surface treatment, stamping die manufacturing, laser cutting, lathe turning parts |

| Application | Industry, automobile, agriculture, medical care, food, new energy, mining |

| Material | Aluminum, copper, stainless steel, plastic, iron, special alloys |

| Surface Treatment | Anodizing, sandblasting, painting, powder painting, electroplating, polishing, laser engraving |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Service Project | We can provide production design, massive production, technical service, in-site stamping molding making service. |

| Testing Machine | Video Measuring system, Microscope, Digital Force Gauge, caliper, projector, roughness tester, Salt- spray machine,Stereomicroscope and so on |

| Packing | Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Wood Cutting Machines

Used in the woodworking industry to cut and shape wood for furniture and other products.

Lathes

For turning and cutting cylindrical or round-shaped parts.

CNC Milling Machines

Used for precise cutting and shaping of materials like metal and plastic.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

At PrecisionCast CNC, quality control is at the core of every process. We implement rigorous inspection protocols throughout production to ensure that every stainless steel part meets exacting standards for precision, durability, and performance. Using advanced measurement tools and testing equipment, we verify dimensional accuracy, surface finish, and structural integrity. Our commitment to excellence guarantees that each product delivers reliable and consistent results, adhering to the highest industry requirements.

Processing capability

PrecisionCast CNC boasts comprehensive processing capabilities to deliver high-quality stainless steel parts. We utilize advanced CNC machining, precision casting, and finishing techniques to produce parts with exceptional accuracy and durability. Our state-of-the-art equipment supports complex geometries and tight tolerances, catering to a wide range of industrial applications. With expertise in custom designs and a focus on efficiency, we ensure optimal performance and cost-effective solutions tailored to meet diverse customer requirements.

Additional processes

PrecisionCast CNC offers a range of additional processes to enhance the quality and functionality of stainless steel parts. These include surface treatments such as polishing, plating, and coating for improved aesthetics and corrosion resistance. We also provide heat treatments to optimize mechanical properties, as well as welding and assembly services to deliver ready-to-use components. Our commitment to precision extends to custom finishing solutions, ensuring every part meets specific application needs with unmatched quality and performance.