Product Description

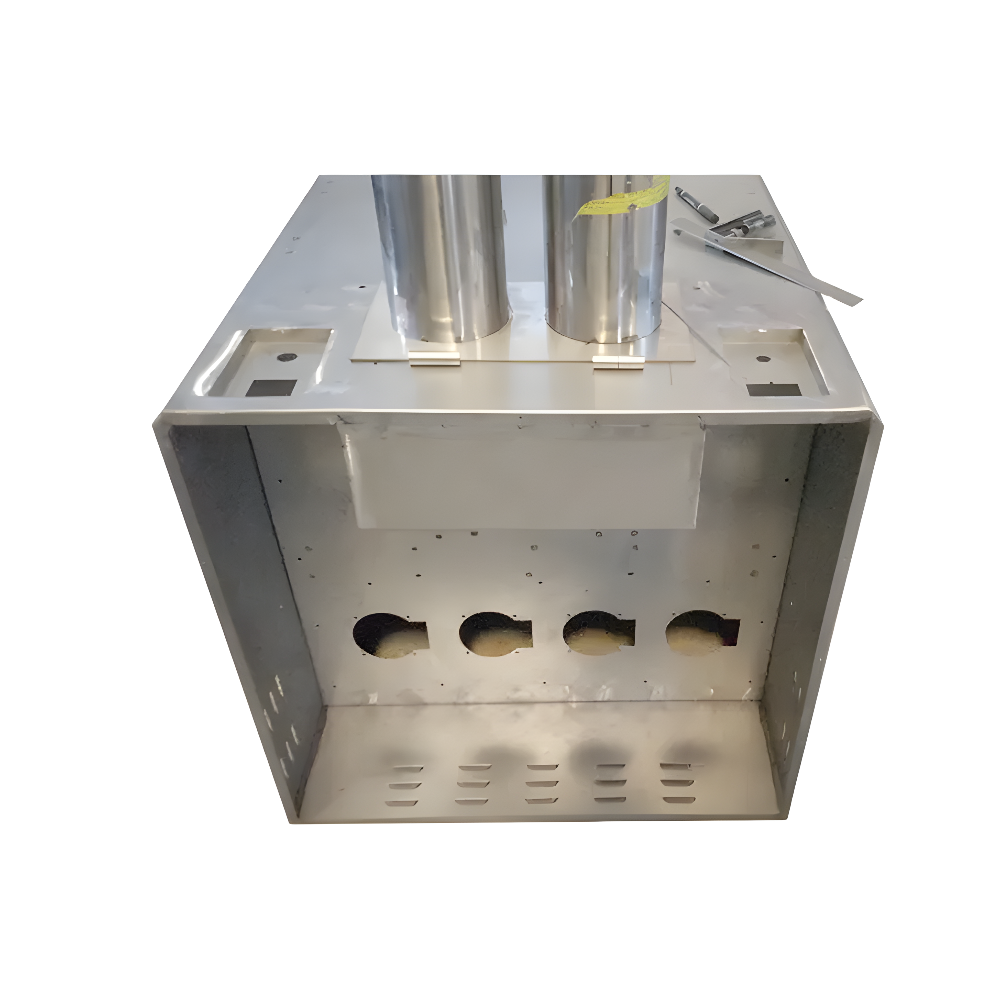

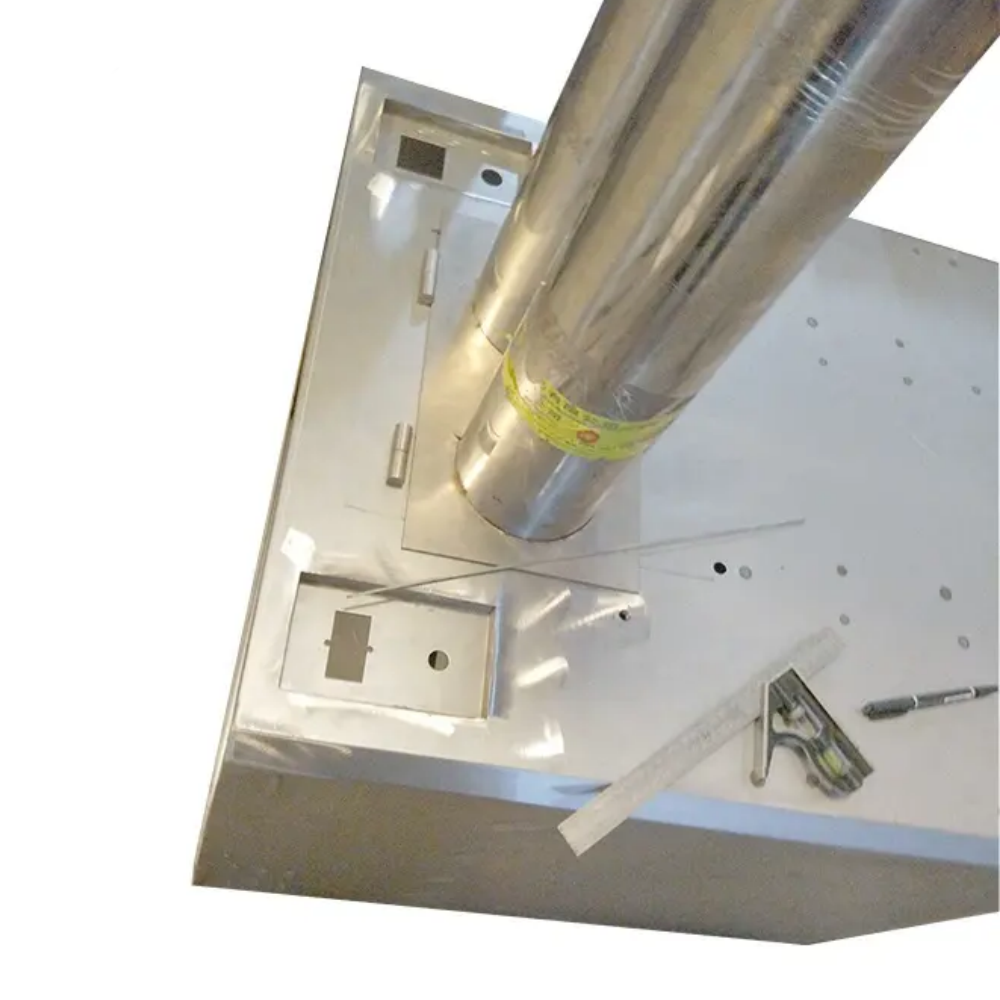

Erik is a leading welding service provider that brings together the expertise and capabilities of multiple integrated factories, offering a comprehensive range of welding solutions for industries of all sizes. Our commitment to quality and precision sets us apart, as we combine advanced technologies with a skilled workforce to deliver consistent and reliable results. Beyond welding, we extend our services to include custom fabrication, machining, assembly, and design, making us a versatile partner for all your industrial needs. Whether it's small-scale production or large, complex projects, our goal is to provide tailored solutions that meet the highest standards of performance, durability, and safety. As a supplier you can trust, we prioritize building strong, long-term relationships with our clients, ensuring timely delivery and unmatched customer service at every stage of the project. Our diverse portfolio and integrated approach allow us to streamline production, reduce lead times, and provide cost-effective solutions that help our clients stay competitive in an ever-evolving market.

Product parameters

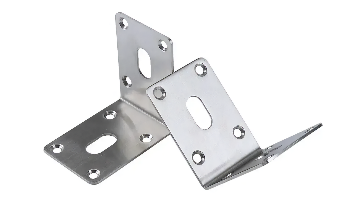

| Optional Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) Galvanized sheet |

| Thickness | 0.8mm, 1.0mm, 1.5mm, 2.0mm and any thickness. |

| Size | According to the drawings,samples or your requests. |

| Drawing Format | 3D/CAD/Dwg/IGS/STP |

| Additional | Sample Order and Small Order are acceptable |

| Accuracy | Accuracy Of Machining: +/-0.01 mmAccuracy of Grinding: +/-0.005 mm Surface Roughness: Ra0.8 Parallelism: +/-0.005mm Verticality:+/-0.005mm Concentricity: 0.003mm |

| Design Measurement | Accept customization,various painting colors,shapes,sizes available.You'd better give us the design drawing. Of course if not we can provide professional design service. |

| More Custom | Surface printing designIndustrial appearance design Structure design Whole system design |

Custom Process

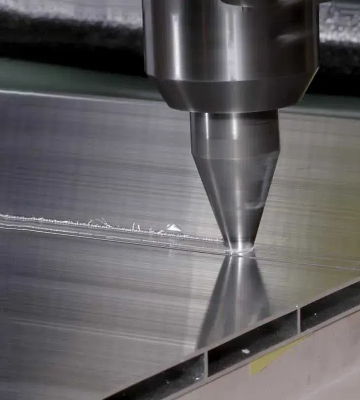

Design and Programming

Machine Setup

Welding Process Execution

Post-Welding Inspection

Process Type

Newer Welding

Gas Welding

Solid State Welding

Material

Metal

Aluminum

Brass

Copper

Quality Control

Custom sheet metal fabrication ensures that all components meet the required specifications and industry standards. The process starts with a comprehensive inspection of the raw materials, checking for factors like thickness, material grade, and surface finish. Throughout production, regular dimensional checks, visual inspections, and non-destructive testing are performed to maintain precision and prevent defects. Quality control also monitors critical fabrication processes, including welding, cutting, and bending, to avoid issues such as warping or misalignment. After fabrication, the parts undergo rigorous testing to assess their strength, durability, and functionality. Detailed QC documentation is often provided to confirm compliance with both customer requirements and industry standards.

Processing capability

Our processing capabilities encompass a wide range of sheet metal fabrication techniques, allowing us to deliver high-quality, precision components tailored to meet diverse customer needs. With advanced equipment and skilled technicians, we specialize in processes such as laser cutting, CNC punching, welding, bending, and forming. We also offer custom finishing options, including powder coating, anodizing, and polishing, to ensure the final product meets both functional and aesthetic requirements. Whether you need prototypes or high-volume production runs, our flexible capabilities enable us to handle projects of any complexity while maintaining exceptional accuracy and turnaround times.