Product Description

OEM service for high-precision CNC Lathe turned parts with micron-level accuracy, supporting large-scale production for automotive, machinery, and electronics industries. We ensure consistent quality, tight tolerances, and on-time delivery, utilizing advanced CNC technology and skilled expertise to meet the most demanding production requirements. Partner with us for reliable and efficient manufacturing solutions tailored to your specific needs.

Product parameters

Product Description

| Material | Titanium, Aluminum, Stainless Steel, Copper, Brass, Galvanized, etc. |

| Size | Customized |

| Surface Treatment | Powder Coating, Electroplating, Oxide, Anodization |

| Technics | Laser Cut, Bend, Weld, Stamp |

| Application | Aerospace, Appliance, Auto, Building, Capital Equipment, etc. |

| Sample | Need to pay sample fee |

| OEM | Accept |

| Drawing Format | 3D/CAD/DWG/IGS/STP |

| Tolerance | According to customer’s request |

Packaging & Shipping

| Packaging Details | Inner pearl button, outside carton box, or customized |

| Selling Units | Single item |

| Single Package Size | 10X10X10 cm |

| Single Gross Weight | 1 kg |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

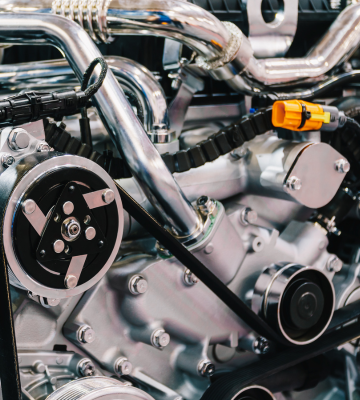

Automotive Engine Components

Parts: Crankshafts, Piston Rods, Valve Shafts

Reason for Use:

CNC lathe-turned parts like crankshafts and piston rods require high precision and strength to handle the mechanical stresses in an engine. These parts must meet strict tolerance levels to ensure the engine runs smoothly and efficiently. CNC turning provides the micron-level accuracy needed for such components, reducing the risk of malfunction and improving the overall performance and durability of the engine.

Aerospace Parts

Parts: Aircraft Fittings, Bushings, Locking Nuts

Reason for Use:

In aerospace, every component must adhere to stringent standards of precision and reliability due to the critical nature of the application. CNC lathe turning allows the production of lightweight, strong, and highly accurate parts such as bushings and fittings, ensuring safety and optimal performance in aircraft systems.

Industrial Machinery Components

Parts: Shafts, Spindles, Gears

Reason for Use:

For industrial machinery, parts like shafts and spindles require exacting tolerances and robust mechanical properties to withstand heavy loads and high-speed operations. CNC turning is ideal for these components, as it ensures the precise dimensions and smooth finishes necessary for high-efficiency performance in machinery.

Material

Copper

Stainless Steel

Aluminum Alloy

Quality Control

Quality control for OEM CNC Lathe parts turning ensures precise dimensions, surface finish, and material strength. Each part is inspected for accuracy and tight tolerances, with continuous monitoring throughout production to detect defects early and ensure high-quality, reliable parts.

Processing capability

The processing capability of OEM CNC Lathe parts turning includes handling a wide range of materials such as aluminum, stainless steel, titanium, and brass. With high-precision CNC machines, it can achieve tight tolerances and complex geometries, making it suitable for various industries like automotive, aerospace, and machinery. The process is capable of producing parts with high accuracy, smooth surface finishes, and consistent quality, whether for small or large-scale production. Advanced tools and technologies ensure efficient material removal, allowing for the creation of intricate parts with fast turnaround times while maintaining durability and performance.

Additional processes

Additional processes for OEM CNC Lathe parts turning may include secondary operations such as milling, drilling, tapping, threading, and polishing to enhance the functionality and finish of the parts. Surface treatments like anodizing, plating, and powder coating can also be applied to improve corrosion resistance and aesthetic appeal. These additional processes ensure that the final product meets specific requirements for performance, durability, and appearance, making it suitable for a wide range of applications across various industries.