Product Description

Our welding fabrication service offers customized metal joining solutions for a wide range of industrial applications. We specialize in various welding techniques, including MIG, TIG, Stick, and Flux-Cored, to meet specific material and design requirements. Our skilled team ensures precision and quality, handling materials such as steel, stainless steel, and aluminum. We offer both small and large-scale fabrication, from single components to full assemblies. The service includes cutting, bending, and finishing to ensure seamless integration into your projects. Quality control is maintained throughout to ensure durability, strength, and adherence to safety standards.

Product parameters

| List | Details |

|---|---|

| Product name | Professional Precision Cnc Machining Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | Customers' Requirement |

| Process | CNC Macining |

| Application | Industrial Equipment |

| OEM/ODM | Accecpted |

| Payment terms | T/T 30% Prepayment |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

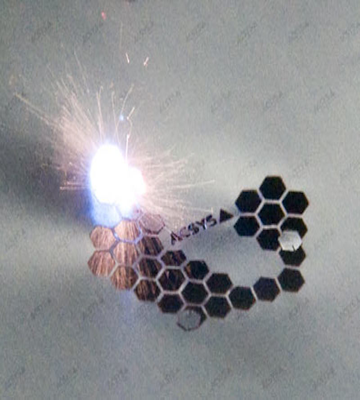

Process Type

Flame Laser Cutting

Melt Cutting

Remote Laser Cutting

Material

Metal Sheet

Aluminum alloy

Brass Sheet

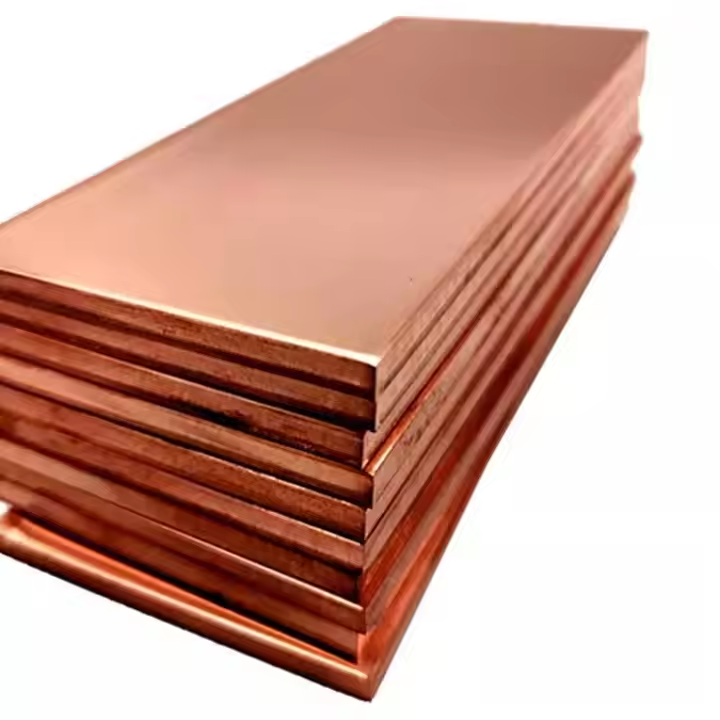

Copper Sheet

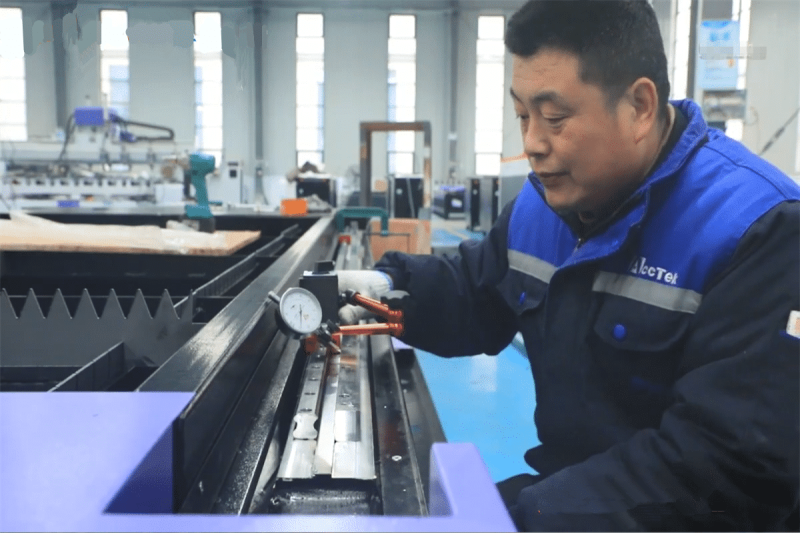

Quality Control

Quality control (QC) in our welding fabrication service ensures the highest standards of precision and safety. Each weld is inspected for proper penetration, alignment, and finish to meet specified requirements. We conduct visual inspections, ultrasonic testing, and x-ray examination to detect any defects like cracks or voids. Weld strength and durability are further assessed through mechanical testing, such as tensile and bend tests. Our team follows strict industry standards, including AWS and ASME guidelines, to ensure compliance. All fabricated parts undergo final inspection to verify dimensional accuracy and overall quality before delivery.

Processing capability

Our welding fabrication service offers extensive processing capabilities, catering to a diverse range of industries and applications. We specialize in welding various metals, including mild steel, stainless steel, aluminum, and alloys, with expertise in multiple welding techniques such as MIG, TIG, Stick, and Flux-Cored. These methods allow for precise and durable joints, whether for thin sheets or thick structural components. Our facilities are equipped with advanced machinery for cutting, bending, and assembly, ensuring high efficiency and accuracy in every project.

Additional processes

We can fabricate both simple and complex components, ranging from small, intricate parts to large structural assemblies. Our team is capable of handling both custom one-off projects and large-scale production runs, delivering high-quality results on time. We also provide post-welding services, including grinding, polishing, and painting, for a finished product ready for installation. The integration of CNC-controlled machines and robotic welding ensures consistent precision and repeatability. Our welding process is suitable for producing products such as frames, tanks, brackets, and pipelines, meeting stringent industry standards and client specifications. With a focus on quality, we offer full traceability and documentation for every project.