Product Description

The bending process of steel material involves the deformation of steel sheets, plates, or bars using mechanical force to achieve a desired angle or shape. This process utilizes specialized equipment such as press brakes, roll benders, or hammering tools to apply controlled force, causing the steel to bend without breaking. It is commonly used in the manufacturing of structural components, frames, and metal parts. The bending process can be performed on various types of steel, including carbon steel, stainless steel, and alloy steel. The material's thickness, tensile strength, and desired radius influence the bending parameters. Proper tooling and techniques ensure precision and avoid cracking or distortion.

Product parameters

| List | Details |

|---|---|

| Brand Name | bending Process Steel Material |

| Surface treatment | Anodizing/electroplating/PVD/Nickel/Chrome Plating |

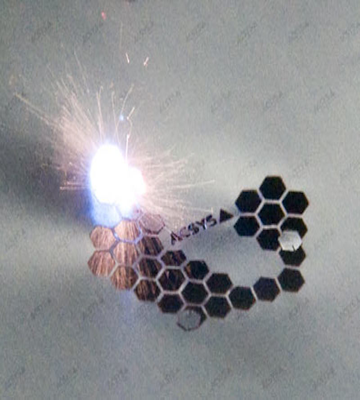

| Processing | LASER CUTTING CNC |

| Service | Custom Sheet Metal Laser Cutting Bending stamping welding Fabrication |

| Precision control | Min +/-0.01mm |

| facility certification | ISO9001:2015 |

| Industrial experience | 6+years |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Flame Laser Cutting

Melt Cutting

Remote Laser Cutting

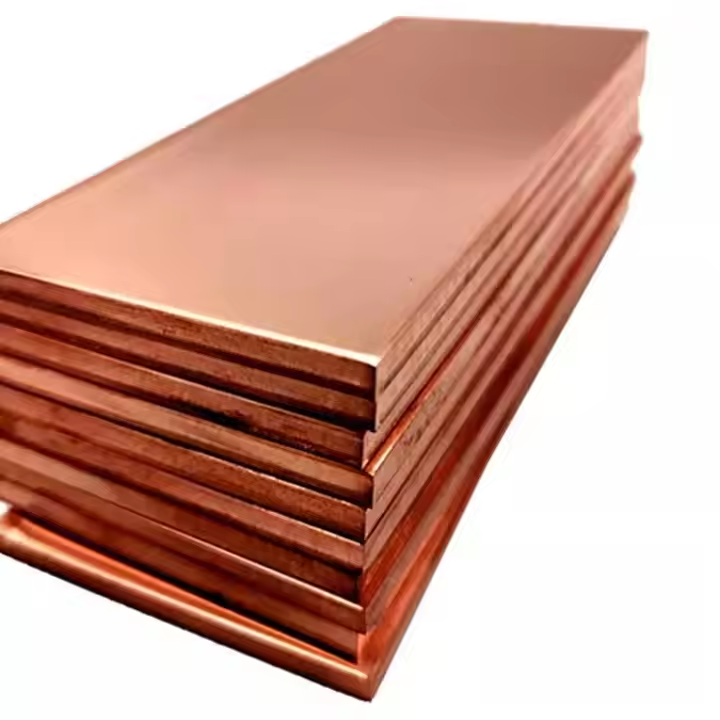

Material

Metal Sheet

Aluminum alloy

Brass Sheet

Copper Sheet

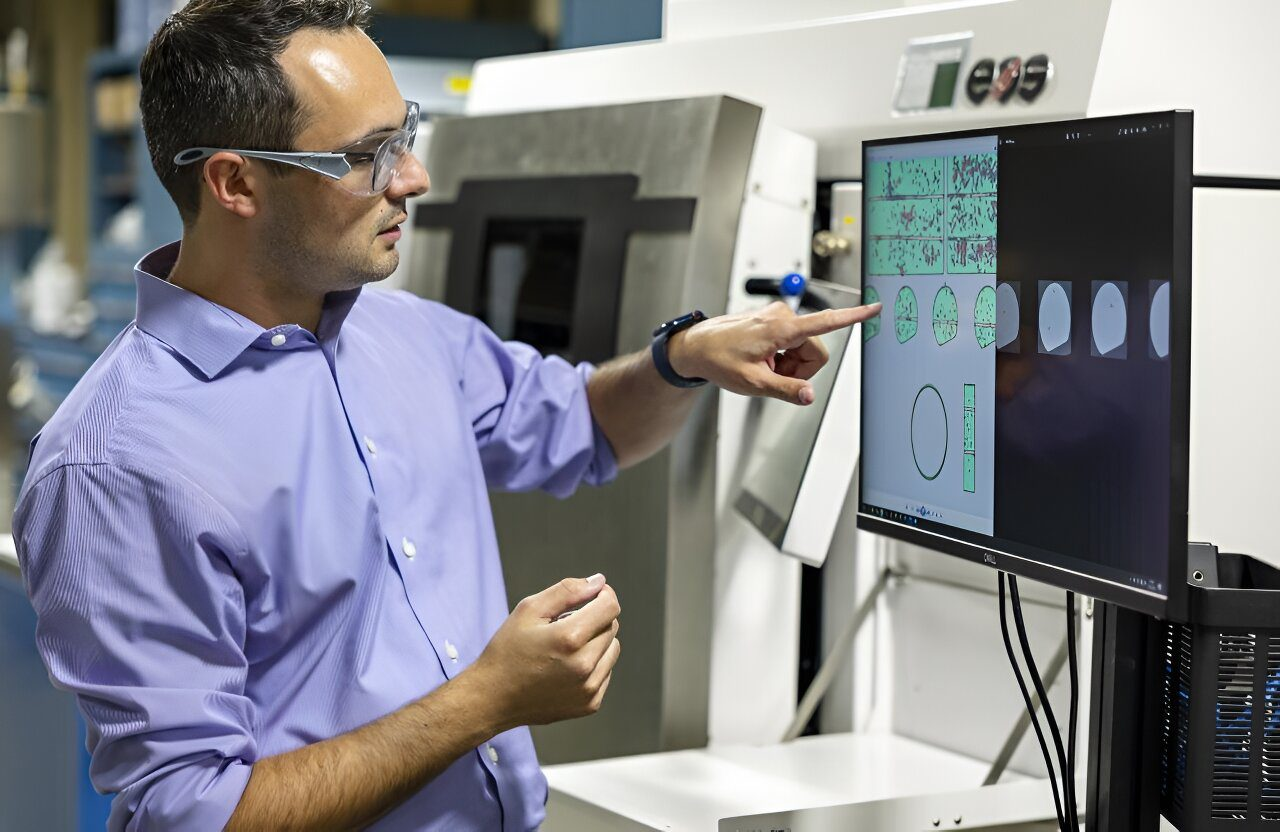

Quality Control

Quality control (QC) in the steel bending process ensures that the final product meets required specifications and standards. QC involves monitoring key factors such as material thickness, bend radius, and angle accuracy during production. Inspecting for surface defects, cracks, or irregularities is critical to maintaining material integrity. Advanced tools like digital gauges and laser measuring systems are often used to check bend angles and dimensions. Additionally, the consistency of the bending force applied is regularly assessed to prevent deformation or uneven bending. Post-bending, steel samples may undergo stress tests to verify their strength and performance.

Processing capability

The bending process for steel material offers a broad range of capabilities, making it highly adaptable for various manufacturing needs. It can accommodate different steel types, including carbon steel, stainless steel, and alloy steel, in various thicknesses, from thin sheets to thicker plates. The process allows for bends of various angles, from shallow to sharp, and can achieve precise radii based on the material's properties and the required design specifications.

Advanced equipment, such as press brakes, roll benders, and CNC-controlled machines, enhances the accuracy and repeatability of the process. This ensures that complex and intricate shapes can be produced with high precision.

Additional processes

The process can handle both small batch runs and large-scale production, offering flexibility for custom and mass manufacturing. The bending capabilities include both air bending, where the material is lifted and deformed, and bottoming, which creates more precise angles.

Additionally, steel materials can be bent in multiple directions, allowing for the creation of 3D components and parts. The process can also be combined with other methods like welding, cutting, or punching to achieve more complex shapes or assemblies. The ability to maintain tight tolerances and high-quality finishes makes the bending process ideal for a wide range of industries, from automotive and aerospace to construction and heavy machinery.