Product Description

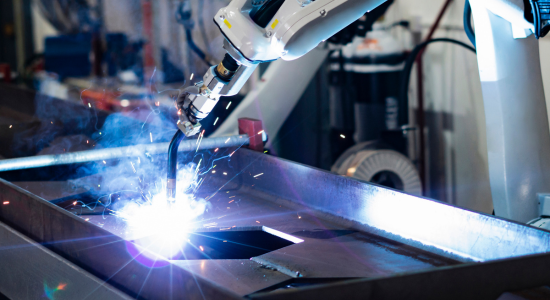

Our metal folding service specializes in bending and shaping metal sheets into precise angles and forms for various industrial applications. Using advanced folding machines, we handle a wide range of metals, including steel, aluminum, and stainless steel, ensuring high accuracy and smooth finishes. The process allows for the creation of custom parts, such as panels, enclosures, and structural components, with minimal distortion. We offer flexible solutions for both small and large production runs, maintaining strict tolerances. Our team ensures quality control throughout, providing parts that meet your design specifications and requirements. With fast turnaround times, we help streamline your manufacturing process while maintaining exceptional quality.

Product parameters

| List | Details |

|---|---|

| Brand Name | Metal Fold Service |

| Process1 | Laser cutting, stamping, bending, welding, surface treatment, packing |

| Material | Stainless Steel |

| Process | Stamping |

| Surface treatment | Sand blasting, anodizing, powder coating |

| Size | Client's Drawings |

| Application | sheet metal fabrication |

| Service | Sheet Metal Fabrication Stamping Bending Welding Turnning Parts |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

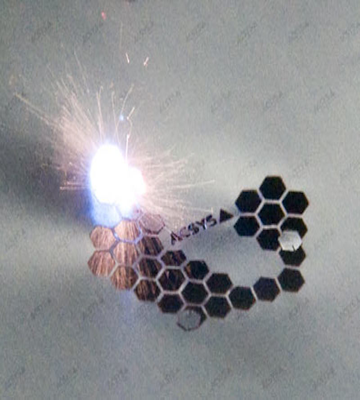

Process Type

Flame Laser Cutting

Melt Cutting

Remote Laser Cutting

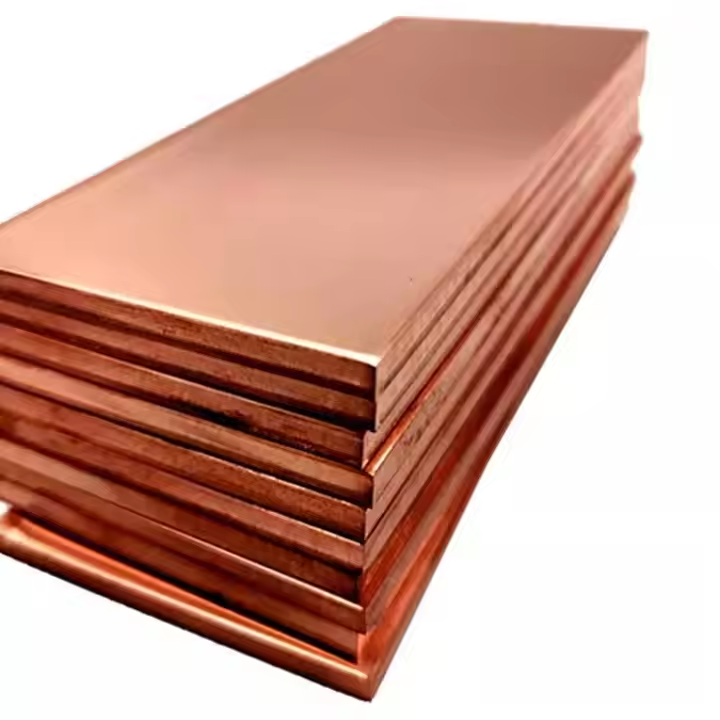

Material

Metal Sheet

Aluminum alloy

Brass Sheet

Copper Sheet

Quality Control

Quality control (QC) in our metal folding service ensures that each component meets precise specifications and industry standards. We inspect the material for defects before folding to ensure consistency and structural integrity. Advanced measuring tools, such as digital gauges and laser systems, are used to verify angle accuracy and dimensional precision. During the process, we monitor fold radius and material deformation to prevent any distortion. Post-folding, each part undergoes thorough visual and dimensional inspections for defects like cracks or uneven bends. Our QC procedures guarantee that all folded metal parts are durable, reliable, and meet customer requirements.

Processing capability

Our metal folding service offers versatile processing capabilities, catering to a wide range of industries and metal types. We work with various materials, including mild steel, stainless steel, and aluminum, and can handle sheet thicknesses ranging from thin gauges to thicker plates. Our advanced folding machines provide high-precision bends, allowing us to achieve tight tolerances and complex geometries, including custom angles, sharp bends, and intricate shapes.

Additional processes

The service supports both small-scale custom projects and large-volume production runs, with quick turnarounds to meet tight deadlines. Our team can create parts such as panels, brackets, and frames, with consistent quality throughout the process. The folding process is ideal for creating components with smooth, clean bends, minimizing the need for additional finishing. We can achieve a variety of bend radii, and our machinery ensures minimal distortion, even on thicker materials. Additionally, we offer secondary operations like punching, cutting, and welding to provide a complete solution. Our capabilities are enhanced by advanced CNC technology, ensuring repeatability and accuracy for each project.