Product Description

The AGV shuttle clamping fork fork lever motor has a precise and powerful power output, can quickly respond to instructions, and efficiently complete the fork action to ensure that the goods are clamped and handled accurately. Its stable and reliable performance is enough to adapt to the complex and changing logistics environment. Whether it is long-term high-intensity operation or frequent start-stop operation, it can always maintain an excellent state. The compact structural design not only saves valuable space, but also facilitates installation and maintenance, providing a solid guarantee for the smooth operation of the AGV shuttle in the field of warehousing and logistics, and is an indispensable assistant for modern smart logistics.

Product parameters

| Parameter name | Parameter Value |

|---|---|

| Operating voltage range | 5.0~29.0V |

| No-load current | ≤100 mA at 24.0V |

| Locked-rotor current | ≤1.5A at 24.0V |

| Locked-rotor torque | ≥8 Kgf.cm at 24.0V |

| Direction of rotation | CW(0→4096) |

| Signal width range | 0→4096 |

| Operable angle | 360°±10° |

| Actuable angle range | 360° |

| Weight | 310±5g |

| Communication method | UART |

| Tensile force level | 50KG |

| Closed loop feedback | Position/speed/voltage/current/temperature |

| Protection mechanism | Overload protection/overcurrent protection/overvoltage protection |

Product Display

- Brushless motor + magnetic encoder | Long life | Good stability | Long, medium and short levers are optional

- RS485 servo integrated design

- Steel transmission structure design

- 40℃ low temperature resistance

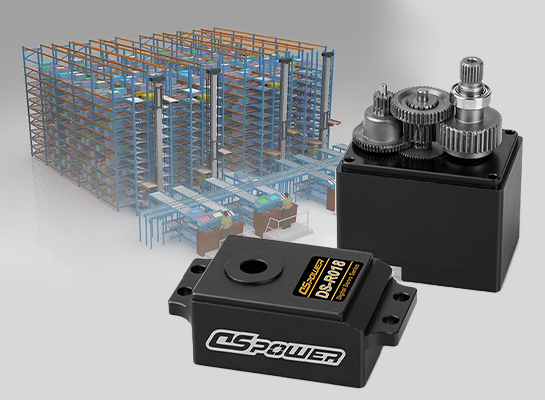

Servo integrated modular design + RS485 bus

- Closed-loop design, multiple feedbacks - complete status control

- Factory preset stall protection

- One-click setting of the neutral position - ensuring installation consistency

Ingenious steel transmission structure design - resistant to material box impact

- Continuous load over 1200 hours, life span 2 million times+

- Isolated conductive, anti-reverse connection protection

- Customizable lever

Smart design, high performance, long life

Steel transmission structure + brushless motor + magnetic encoder

Super ability to adapt to the environment

-40°C~+85°C, ≤90%RH

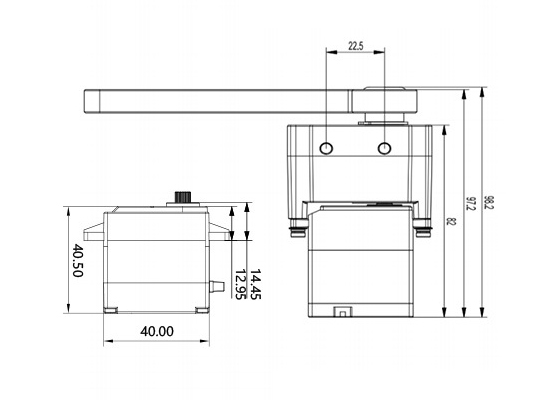

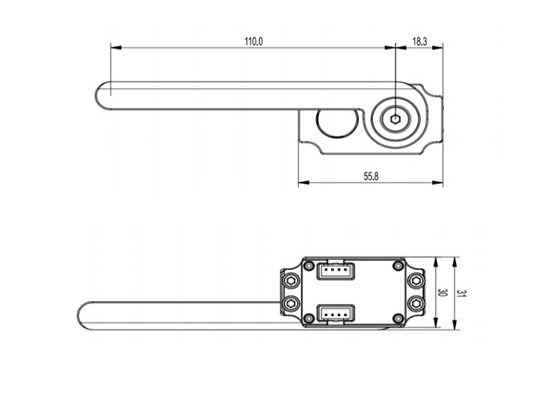

Size & Interface

Application Cases

- In smart factories, AGV shuttles use this logistics servo to accurately clamp and pick up goods, efficiently complete material distribution, and greatly improve production efficiency.

- In e-commerce warehouses, this servo helps AGV shuttles quickly move goods and accurately place goods in designated locations, reducing labor costs and error rates.

- In logistics distribution centers, this motor of AGV shuttles runs stably, clamps and holds various types of goods in an orderly manner, realizes rapid loading and unloading and transportation of goods, and optimizes logistics processes.

Service

Adhere to self-production and self-research: strictly control from design to production process

Adhere to 100% full inspection: ensure the stability and consistency of delivery quality

Adhere to good materials: good craftsmanship + good materials + good quality, the ultimate cost-effectiveness

Adhere to customer-centricity: match the appropriate solution according to the needs, and refuse performance redundancy

Modular R&D ideas, product functions can be matched at will: reduce customization and shorten the R&D cycle