Product Description

CNC Machining Alloy Spare Parts are precision-engineered components designed for high performance and durability. Manufactured using advanced CNC machining techniques, these parts are made from high-quality alloy materials that offer excellent strength, resistance to wear, and corrosion. They are ideal for a wide range of industries, including automotive, aerospace, and manufacturing. The parts are custom-made to meet specific design requirements, ensuring tight tolerances and smooth finishes. With exceptional reliability and consistency, these alloy spare parts ensure optimal performance in demanding applications. They are perfect for both high-volume production and custom one-off designs.

Product parameters

| List | Details |

|---|---|

| Brand Name | Cnc small Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys, Engineering Plastic |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Processing Type | 3/4/ 5 Axis CNC Machining |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Tolerance | 0.01- +/-0.005mm |

| Material | Aluminum Alloy |

| Quality control | 100% Inspection |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

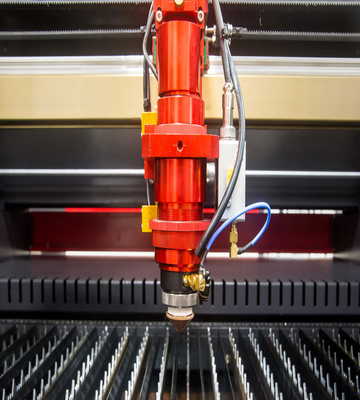

Laser Cutting

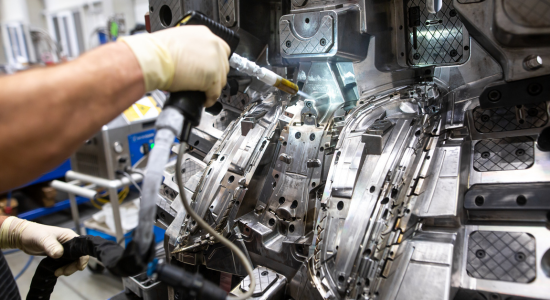

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The quality control (QC) for CNC Machining Alloy Spare Parts involves rigorous inspection at every stage of production. Each part is checked for dimensional accuracy, ensuring tight tolerances are met. Material integrity is verified to ensure the alloy used meets specified strength and durability requirements. The surface finish is inspected to ensure smoothness and the absence of defects. Parts undergo functional testing to confirm performance under operational conditions. Final inspection includes thorough checks for consistency, reliability, and compliance with customer specifications, ensuring the highest standards of quality.

Processing capability

CNC Machining Alloy Spare Parts offer exceptional processing capabilities, enabling the production of highly precise and complex components. Utilizing advanced CNC technology, these parts can be machined with tight tolerances and high accuracy, ensuring a perfect fit for various applications. The process includes turning, milling, drilling, and tapping, allowing for versatile part designs and configurations.

With the ability to handle a wide range of alloy materials, such as aluminum, brass, stainless steel, and titanium, CNC machining ensures the parts maintain superior strength, wear resistance, and corrosion protection. The advanced CNC machines provide high-speed cutting, allowing for efficient production while maintaining high quality and consistency.

Additional processes

The process can be customized for both small and large production runs, making it suitable for diverse industries such as automotive, aerospace, medical, and electronics. CNC machining also allows for the creation of intricate designs, including complex geometries and detailed features. Automated tool changers and multi-axis capabilities further increase production flexibility, enabling the machining of parts with high precision and smooth finishes.

Moreover, CNC machining ensures repeatability, meaning parts can be produced in large quantities with consistent quality and dimensional accuracy, making it ideal for both prototyping and mass production.