Product Description

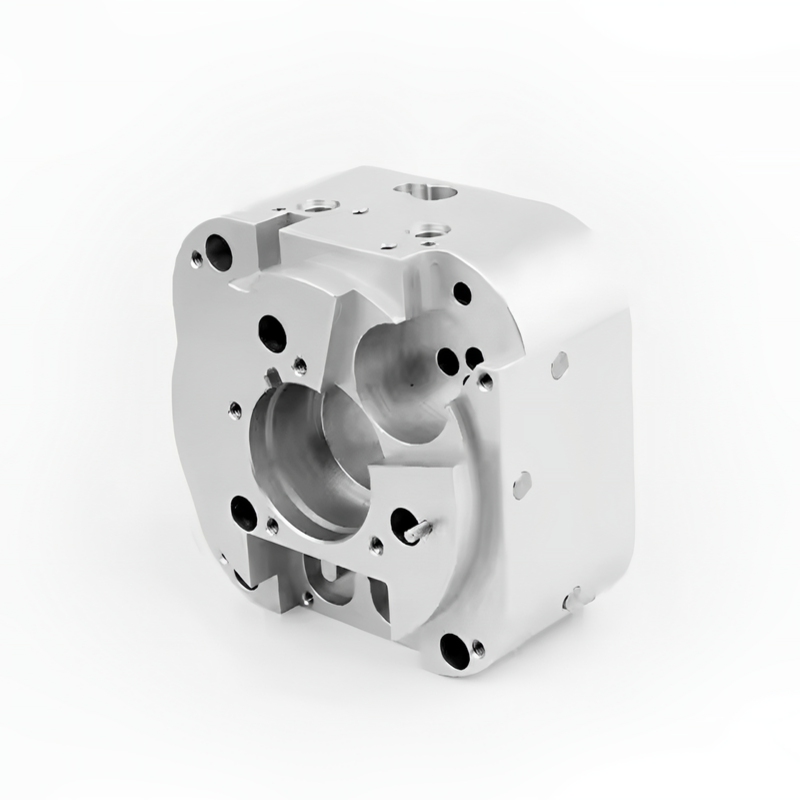

Precision Shrink Fit Holder High: Ensures exceptional tool stability, high concentricity, and vibration-free machining for maximum precision in demanding applications. Designed with advanced thermal shrinking technology, it guarantees a secure grip and minimizes tool runout, enhancing machining performance and extending tool life.

Product parameters

| Use | Thread Turning Tool |

| Hardness | HRC52 |

| Coating | No |

| Warranty | 1 Year |

| Customized Support | OEM, ODM |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

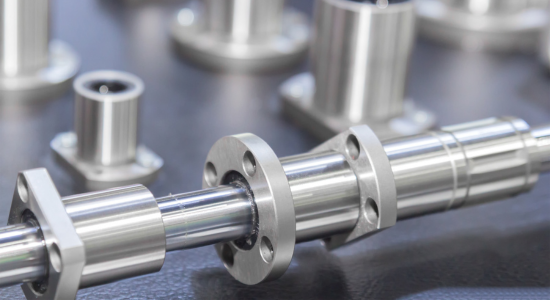

5-Axis CNC Milling Machine

- Reason: The 5-axis CNC milling machine is capable of moving in multiple directions simultaneously, making it ideal for complex parts like those used in aircraft or machines with intricate shapes. The ability to machine in multiple axes simultaneously allows for the creation of highly detailed and precise parts without the need to reposition the workpiece, improving production efficiency and precision.

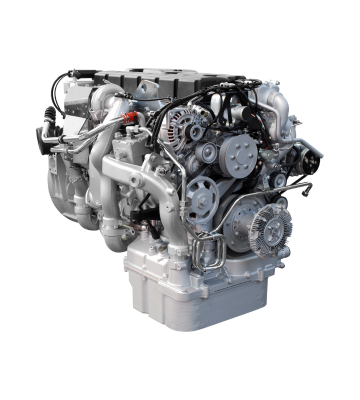

Automotive Engine Block Milling Machine

- Reason: This milling machine is used for machining automotive engine parts, such as engine blocks. The primary advantage is its ability to reduce vibrations during machining, which ensures high precision and durability for components used in engines. Reducing vibrations results in stable cutting and prevents inaccuracies in the final part, ensuring high quality and reliability.

High-Speed Drill Press

- Reason: A high-speed drill press is designed to drill holes in various materials efficiently and quickly. It improves productivity by allowing for precise drilling at high speeds, ideal for tasks requiring numerous holes in a short time frame, maintaining accuracy in hole size and location while improving throughput.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

The Quality Control of Precision Shrink Fit Holder High should cover various aspects, including the accuracy in manufacturing to maintain the balance and precision of tool holding during production. Strict control is required with high-standard equipment, such as precise measuring tools, to check dimensions and clamping force. Testing the tool holding performance under real-use conditions is essential to ensure the tool does not loosen during operation

Processing capability

The processing capability of Precision Shrink Fit Holder High involves the ability to maintain high precision and stability during machining processes. It ensures that tools are securely held with minimal runout, which is crucial for achieving high-quality finishes and precise cuts. The holder's design allows it to withstand high rotational speeds and extreme cutting forces, providing reliable performance even in demanding machining environments.

Additional processes

The additional processes for Precision Shrink Fit Holder High include heat treatment and surface finishing to enhance durability and performance. The heat treatment process ensures that the holder achieves optimal hardness and wear resistance, allowing it to withstand the stresses of high-speed machining. Surface finishing is applied to improve the smoothness and reduce friction, preventing premature wear and ensuring a secure fit. In some cases