Product Description

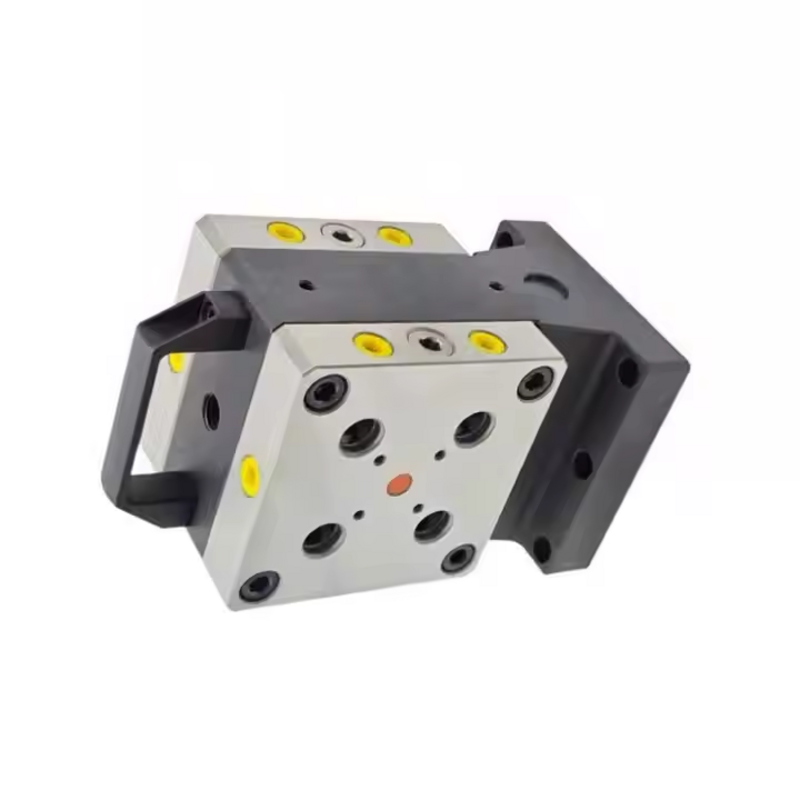

The CNC Self Centering Vise delivers precise clamping, optimal centering, and robust stability, ensuring consistent accuracy for high-performance machining tasks. Designed with advanced engineering, it guarantees that the workpiece is centered automatically, reducing setup time and improving workflow efficiency.

Product parameters

Other attributes

| Weight (kg) | 3 |

| Warranty | Unavailable |

| Core Components | Base, Screw, Jaw |

| Video Outgoing Inspection | Not Available |

| Machinery Test Report | Not Available |

| Style | 85/120/160/L35/L60/L100 |

Packaging and delivery

| Selling Units | Single item |

| Single Package Size | 27X27X27 cm |

| Single Gross Weight | 5.000 kg |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

5-Axis Machining Center

- Reason: 5-axis machining involves handling workpieces at multiple angles and axes. The Self Centering Vise securely holds the workpiece even in complex orientations, reducing the need for frequent machine adjustments, making it ideal for multidimensional tasks such as aerospace or medical components.

CNC Milling Machine

- Reason: CNC milling requires high precision to avoid deviations during machining. The Self Centering Vise ensures accurate positioning of the workpiece, saving setup time and minimizing errors, especially for complex-shaped parts.

CNC Lathe Machine

- Reason: CNC lathes need the workpiece to be perfectly centered on the chuck. The Self Centering Vise simplifies this process by automatically aligning the workpiece to the center, ensuring symmetrical machining, reducing imbalance issues for large workpieces, and enhancing production efficiency.

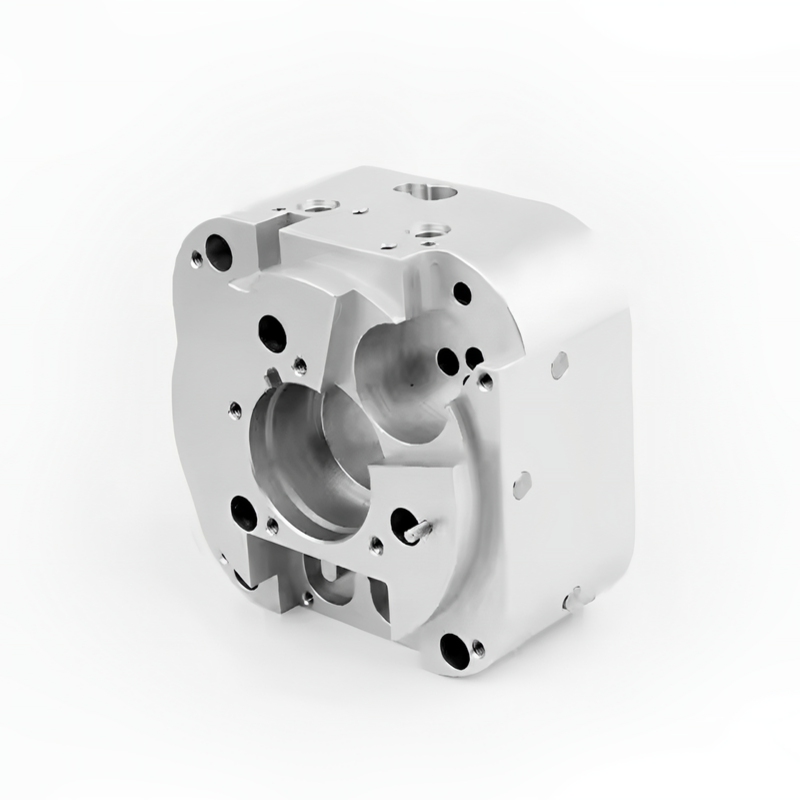

Material

Stainless Steel

Aluminum Alloy

Copper

Quality Control

Quality Control of the CNC Self Centering Vise ensures that each unit meets high standards of precision, durability, and performance. The manufacturing process involves rigorous checks for dimensional accuracy to guarantee that the vise operates with optimal clamping force and precise alignment. Every component, including the base, screw, and jaw, undergoes thorough inspection to detect any defects or irregularities that could affect functionality. The vise's clamping mechanism is tested for smooth operation, ensuring that it can securely hold workpieces without slipping or causing distortion during machining.

Processing capability

The processing capability of the CNC Self Centering Vise is designed to enhance the precision and efficiency of machining operations. Its self-centering mechanism ensures that workpieces are automatically aligned, reducing setup time and minimizing human error. The vise can handle a wide range of materials and workpiece sizes, making it versatile for different machining tasks. It provides consistent clamping force, ensuring the workpiece is securely held during high-speed machining without shifting or loosening.

Additional processes

The additional processes of the CNC Self Centering Vise include heat treatment and surface finishing to enhance its performance and longevity. Heat treatment is applied to improve the material's hardness and resistance to wear, ensuring the vise can withstand the stresses and strains of high-speed machining. Surface finishing, such as coating or polishing, is used to reduce friction, prevent corrosion, and improve the vise's durability.