Product Description

Our CNC machining services for stainless steel offer precision and reliability for a wide range of applications. Utilizing advanced CNC technology, we produce high-quality stainless steel components with tight tolerances and excellent surface finishes. Our expertise covers turning, milling, drilling, and threading to meet custom design specifications. Suitable for industries such as aerospace, automotive, and medical, our stainless steel parts deliver durability, corrosion resistance, and strength. We work with various grades of stainless steel to ensure optimal material properties for each project. From prototypes to large-scale production, our CNC machining ensures consistent, high-performance results.

Product parameters

| List | Details |

|---|---|

| Product name | CNC machined parts |

| Type | Laser Machining, Other Machining Services, Wire EDM |

| Color | Picture Shows |

| Application | Industry |

| Size | Customer Size |

| Feature | Easy Installation Durable |

| Quality Control | Strict Inspection |

| Sample | Samples Offered |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

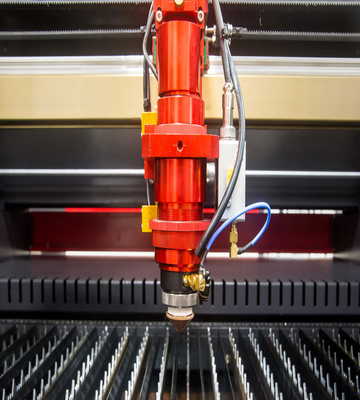

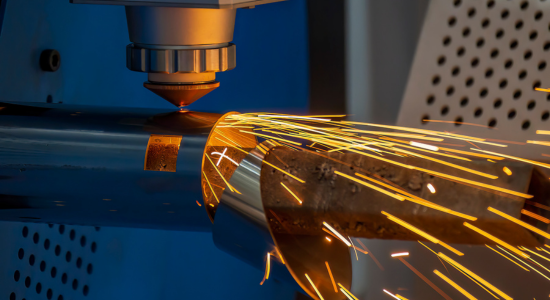

Laser Cutting

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Our QC process for CNC machining of stainless steel ensures the highest standards of precision and quality. Each part is rigorously inspected for dimensional accuracy using advanced measuring instruments like micrometers, calipers, and CMM machines. We check the surface finish to ensure smoothness and meet customer specifications. Material integrity is verified through non-destructive testing to detect any internal defects or inconsistencies. We perform functionality tests to ensure that all parts meet their design and performance criteria. Only components passing these strict QC procedures are approved for delivery, ensuring reliable and durable results.

Processing capability

Our CNC machining capabilities for stainless steel ensure high precision and efficiency across a wide range of complex applications. We utilize advanced CNC turning, milling, drilling, and tapping operations to produce intricate parts with tight tolerances, typically ranging from ±0.005 mm to ±0.1 mm. Our state-of-the-art machines are capable of handling various stainless steel grades, including 304, 316, and 17-4 PH, ensuring optimal material properties such as corrosion resistance and strength.

With the ability to process both small and large batches, our machining services cater to industries such as aerospace, automotive, medical, and manufacturing. We specialize in creating complex geometries, custom profiles, and precise thread designs, all while maintaining superior surface finishes. Advanced CAD/CAM software enables efficient toolpath programming, enhancing machining speed and accuracy.

Additional processes

Our CNC machining process can achieve both high-speed and high-precision operations, making it ideal for tight production schedules. Whether producing prototypes or high-volume runs, we ensure consistency in quality and performance. Post-machining processes such as deburring, polishing, and heat treatment can be incorporated to meet specific project requirements. With a focus on durability and reliability, our CNC machining of stainless steel delivers optimal results for even the most demanding applications.