Product Description

SK-YPC-VC12.1 inch vehicle-mounted industrial control machine is specially designed for industrial vehicles such as engineering mining trucks and forklifts. It is a high-tech equipment with fully enclosed protection, IP65 waterproof and dustproof, and excellent seismic performance. It integrates advanced navigation and positioning functions, providing a reliable guarantee for the accurate operation of vehicles in complex operating environments, and effectively improving the intelligent management level and working efficiency of industrial vehicles.

Product parameters

| selectable Host configuration | Intel Celeron J1900, DDR4-8G, SSD-128G | |

| Intel Celeron J6412, DDR4-8G, SSD-128G | ||

| Intel Core i3-3217U, DDR4-8G, SSD-128G | ||

| Intel Core i5-3317U, DDR4-8G, SSD-128G | ||

| Intel Core i3-7100U, DDR4-8G, SSD-128G | ||

| Intel Core i5-7200U, DDR4-8G, SSD-128G | ||

| Android optional Host configuration | Android A133/2G/16G | |

| Android RK3288/2G/16G | ||

| Android RK3568/2G/16G | ||

| Android RK3568/2G/16G | ||

| Android 3399 4G+32G | ||

| Android configuration host PK | |||

|---|---|---|---|

| CPU model | RK3288 quadrinucleus | RK3568 quadrinucleus | RK3399 hexacaryon |

| architecture | CORTEX-A17 | CORTEX-A55 | Dual-core CORTEX-A72 + Quad-core CORTEX-A53 |

| Dominant frequency | 1.8GHZ | 2.0GHZ | 1.8GHZ |

| Android system | Android 5.1/6.0/ 7.1/8.1 | Android11 | Android 7.1/8.1/9.0 |

| Running points | 75,990 points | 128,342 points | 97,558 points |

| name | argument | name | argument |

|---|---|---|---|

| Model number | SK-YPC-VC | Hard disk capacity | 128GB |

| Memory capacity | 128GB | Warranty period | 12 months |

| Screen size | 12.1 inches | Operating system | other |

| Energy efficiency class | Second level | Whether touch screen | is |

| Memory type | other | Video memory capacity | 8GB |

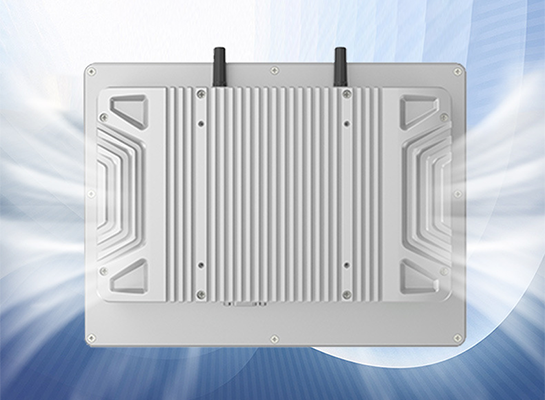

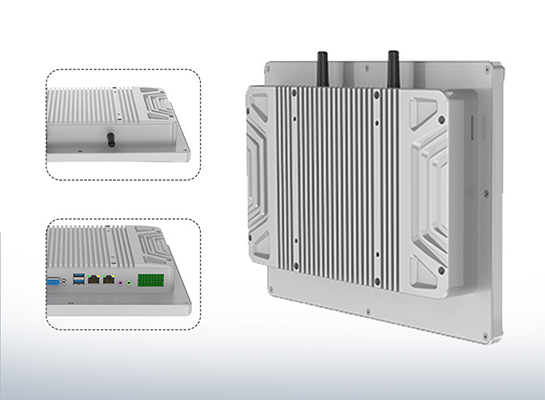

Product Display

Industrial capacitive touch screen

Industrial control machine equipped with 12.1 inch high resolution LCD screen, high brightness and high contrast, can be read under strong light, display all kinds of information clearly. Capacitive multi-touch technology, responsive and accurate, the operation interface is simple, intuitive and ergonomic, convenient for drivers to interact, improve efficiency and comfort.

Fully enclosed fanless powerful heat dissipation

High sealing structure design, effective way dust into the fuselage

Ensure that the internal heat is exported to improve the heat dissipation rate.

Industrial material resistant to high and low temperatures

After strict temperature control box test, the product can adapt to the temperature between -20C~60℃,

No matter in severe winter or heat, it can run stably.

IP65 full screen dust and waterproof

Seamless full screen panel design. The four corner arc and the bezel chamfer are processed to form a sense of beauty combined with the whole cabinet.

In line with the IP65 protection grade standard, it can not only be waterproof and dust-proof, but also resist external shock and vibration to a certain extent, and adapt to the strong vibration and impact of engineering mining trucks, forklifts and other vehicles in the bumpy and rugged road and frequent loading and unloading operations.

All aluminum body casting molding

Fully enclosed design, rear shell porous heat dissipation low noise,

Good heat dissipation effect, strong stability

Greatly improve the machine running speed, effectively ensure the whole machine accessories life

Quality Control

Industrial control machine follows strict quality control system. The selection of raw materials is strict, the purity of the all-aluminum body material is high, and the corrosion resistance is strong. The touch screen and electronic components are from high-quality suppliers and have been tested multiple times. Precision production process control, high CNC machining precision of all aluminum fuselage, vacuum bonding technology for touch screen to ensure no defects, electronic components welding with advanced equipment and accurate setting of parameters, and products through multi-link testing, including performance, compatibility, stability and environmental adaptability testing, to ensure efficient and stable operation in complex industrial scenarios. Build a solid foundation of quality for industrial applications.

Application Cases

Engineering car field: In the process of mining, ore transportation and other operations, provide accurate navigation and positioning for engineering car, help the driver quickly find the working location and driving route, improve transportation efficiency and operational safety. At the same time, it can realize real-time monitoring and data collection of vehicle status by connecting with other equipment on the vehicle, provide data support for the mine management system, and facilitate remote scheduling and equipment maintenance by managers.

Forklift operation scenario: used for navigation and operation guidance of forklifts in large logistics warehouses, factory workshops and other places. The forklift driver can quickly and accurately move the goods to the specified place according to the map and storage location information displayed on the integrated machine, reducing the handling time and incorrect operations. In addition, it can also be integrated with the warehouse management system to realize the automatic management and information recording of goods in and out of the warehouse, and improve the intelligent level of logistics operations and management efficiency.

Other industrial vehicle applications: suitable for a variety of industrial vehicles that need navigation positioning and intelligent management, such as port cranes, yard trucks, sanitation sweepers, etc. In different industrial environments, SK-YPC-VC12.1 inch vehicle industrial control machine can play its stable and reliable performance advantages, providing a strong guarantee for the efficient operation and fine management of industrial vehicles.

Company Introduction

Founded in 2012, Sunke is a state-level high-tech enterprise with its own brand. It has subsidiaries in Beijing, Shanghai, Guangzhou, Foshan, Shenzhen and Hangzhou, with nearly 400 employees.

After more than 10 years of development and accumulation, Senke has formed a diversified business model of R & D design, production and manufacturing, system integration, e-commerce, sales and service, and its main products are industrial three defense terminals, industrial computer, industrial tablet computer, touch teaching machine, LCD advertising machine, LCD splicing screen, LED full color screen and other display products. Its products are widely used, covering industrial Internet, Internet of things, artificial intelligence, high-end equipment, commercial display, big data and other national strategic emerging industries and key areas, industrial products and commercial display products in the Internet market market share has been in the forefront of the industry for many years.

Adhering to the R & D concept of "innovation as vitality", Sunke has established an independent R & D technical team accounting for 20% of the total number of employees, with a mature and forward-looking R & D system, and has more than 100 core hardware and software patented technologies. In 2022, the Shanghai company passed the enterprise certification of specialized new little giant. With its strong hardware and software innovation and iteration ability, Senke has built a solid technical barrier, which has won the high recognition and trust of the domestic and foreign markets, and also made Senke grow into one of the high-tech enterprises with independent core technologies in the field of commercial display in China.

Service

Quality assurance service

The company provides a warranty period for the products sold: LCD screen protector for one year, wire electronic material for three years.

The warranty period is one year from the date of your receipt of the goods. Warranty period, is the product itself quality problems or other non-human factors caused by the failure, you can get free product warranty service (repair within three months, we bear the round-trip freight; If more than three months, each bear the shipping costs). Outside the warranty period, our company charges maintenance, if you need to return to the factory maintenance by the customer to bear the logistics costs.

During the warranty period, our company will repair the damaged parts caused by product quality problems free of charge; If the parts are replaced outside the warranty period or the parts are damaged artificially due to improper use by customers during the warranty period, our company will charge the material cost and manual maintenance fee.

In any of the following cases, the company does not provide free warranty service, but may apply a fee maintenance service:

- The product exceeds the warranty period stipulated by the Company;

- Failure and damage caused by failure to use, maintain and keep in accordance with the instructions for the use of the product;

- Damage caused by the use of a power supply other than the specified voltage;

- Cannot produce warranty card and valid purchase certificate;

- The product does not have any Logo of the company, or the product label and logo of the company are torn or replaced;

- Damage caused by water or other solution caused by improper use of equipment;

- Failure and damage caused by natural disasters and other force majeure (such as earthquake, fire, etc.);

- Failure and damage caused by handling, extrusion, bump, scratch, impact and high temperature after purchase.

- Long-term use of the product appearance wear is not covered by the warranty.