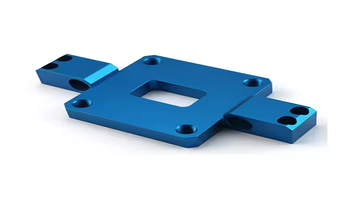

Product Description

Our Aluminum CNC Metal Parts are precision-engineered for superior strength and durability. Manufactured using advanced CNC machining technology, these parts ensure high accuracy and tight tolerances. Ideal for a wide range of industries, including automotive, aerospace, and electronics, they offer excellent corrosion resistance and lightweight properties. Each part is crafted from high-quality aluminum alloy to guarantee long-lasting performance. With custom design options available, our aluminum CNC parts meet specific design requirements and enhance operational efficiency. Reliable, cost-effective, and versatile, they are the perfect solution for your metal part needs.

Product parameters

| List | Details |

|---|---|

| Brand Name | Aluminium CNC Metal Parts |

| Purpose | for manufacturing |

| Usage | Machining equipment CNC machining centers, CNC mi |

| Material | Aluminum, brass, bronze, copper, Hardened metals, Precious metals |

| Processing type | Cutting, drilling, chemical processing, laser processing, milling |

| process | micromachining |

| accuracy | Tolerance 0.01- +/-0.005mm |

| Size | Customized Size |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

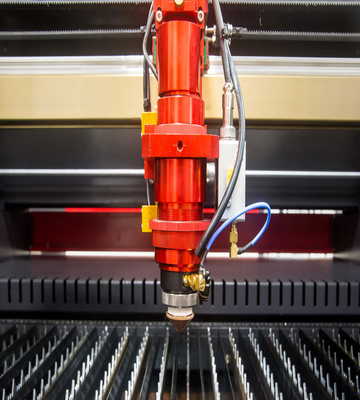

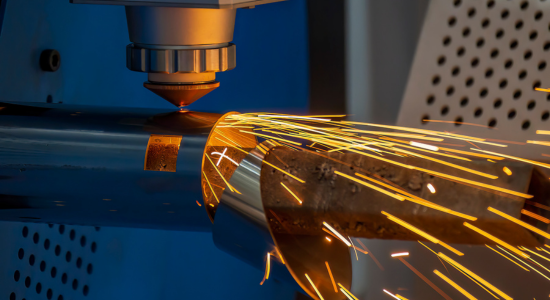

Laser Cutting

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Our Quality Control (QC) process for Aluminum CNC Metal Parts ensures the highest standards of precision and reliability. Each part undergoes rigorous inspection using advanced measuring tools, including micrometers and CMM machines, to verify dimensional accuracy. We conduct visual inspections to detect any surface defects or imperfections. Hardness and material composition tests are performed to guarantee durability and strength. Our team follows strict industry standards and quality guidelines at every production stage. Only parts that meet or exceed our stringent QC criteria are approved for delivery, ensuring optimal performance and customer satisfaction.

Processing capability

Our processing capability for Aluminum CNC Metal Parts is designed to deliver exceptional precision and versatility across a range of complex applications. We utilize state-of-the-art CNC machining technology, including milling, turning, and drilling, to produce parts with high-dimensional accuracy and tight tolerances. Our advanced equipment allows us to handle a wide variety of aluminum alloys, ensuring strength, lightweight properties, and corrosion resistance.

With multi-axis CNC machines, we can achieve intricate designs and complex geometries, providing optimal solutions for industries like aerospace, automotive, medical, and electronics.

Additional processes

Our team is skilled in machining parts ranging from small, detailed components to larger, more robust designs. We also offer a range of finishes, such as anodizing and powder coating, to enhance durability and aesthetics.

From rapid prototyping to large-scale production, we can process both small and large batch orders efficiently. Our capability to manage complex tooling, tooling changes, and material handling ensures consistent high-quality output. We work closely with clients to meet specific technical requirements, maintaining flexibility to adapt to evolving needs while maintaining cost-effectiveness and on-time delivery.