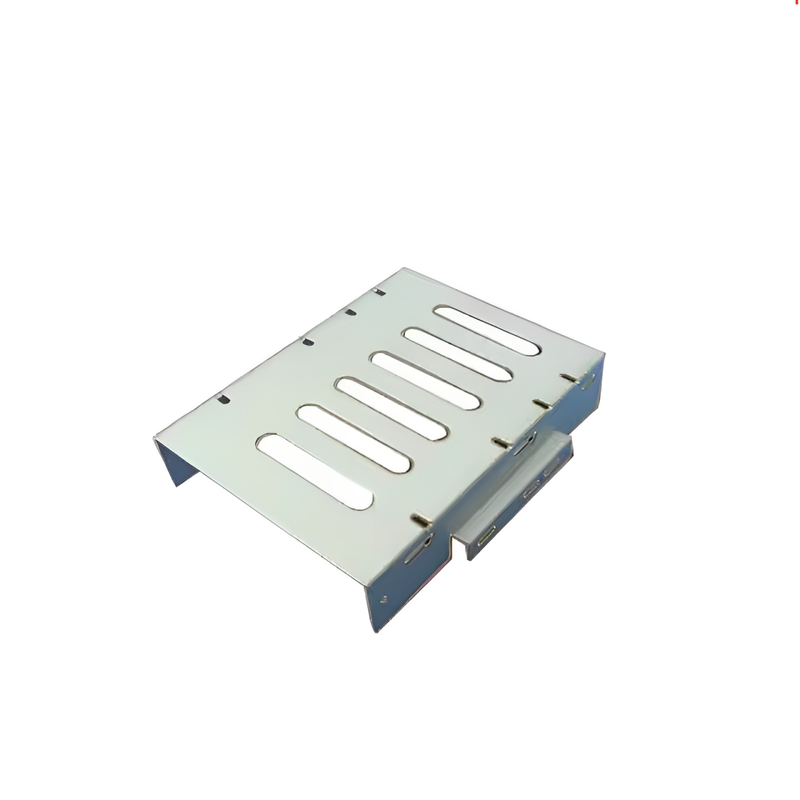

Product Description

High-quality aluminum stamping parts for sheet metal applications. Precision-engineered to meet strict standards, offering exceptional durability and lightweight properties. These parts are designed for versatility, making them ideal for various industrial applications, including automotive, aerospace, and consumer electronics.

Product parameters

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, Titanium, Alloy etc |

| Process | Laser Cutting, Precision Stamping, Bending, Welding, CNC milling, CNC Tuming, Threading, Riveting, Drilling, CNC Punching, |

| Die Casting etc. | |

| Surface treatment | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating, etc. |

| MOQ | 1 PC |

| Size | Customized Size |

| Color | RAL, Pantone, RGB, CMYK |

| Drawing format | STEP, DWG, DXF, IGS, 3DSSTL, SKP, AI, PDF |

| Package | Carton, Wooden Box |

| Place of Origin | Guangdong, China |

| Service | OFM/ODM |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Electronics

- Reason: Metal components in electronics need to be highly accurate and durable for reliable performance.

- Advantage: Stamped metal parts provide precision and durability, ideal for use in devices that experience movement or long-term use.

Industrial Machinery

• Reason: Parts in industrial machinery must be resistant to wear and impact.

• Advantage: Stamped metal parts are strong and durable, making them suitable for heavy-duty industrial use.

Agricultural Equipment

- Reason: Components in agricultural machinery, such as metal frames and connectors, need to withstand heavy-duty operations in tough environments. Custom bending stamping allows for strong, purpose-shaped parts.

Material

Iron

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for aluminum sheet metal stamping parts involves rigorous inspections and testing to ensure precision, consistency, and durability. Each part undergoes dimensional checks, surface finish evaluations, and strength testing to meet strict industrial standards. Advanced tools and techniques, including coordinate measuring machines (CMM) and visual inspections, are used to detect defects and ensure accuracy. This process guarantees high-quality parts that perform reliably in various applications.

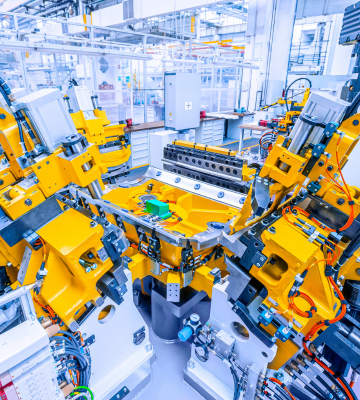

Processing capability

The processing capability for aluminum sheet metal stamping parts includes high-precision forming, cutting, and bending with tight tolerances. Advanced stamping techniques allow for the creation of complex shapes and designs, ensuring consistency and accuracy across large production volumes. The process supports various thicknesses of aluminum and can integrate additional operations such as punching

Additional processes

Additional processes for aluminum sheet metal stamping parts include surface treatments such as anodizing, powder coating, or polishing to enhance durability, corrosion resistance, and appearance. Secondary operations like deburring, welding, laser cutting, and assembly can be performed to meet specific design and functional requirements. Custom engraving, marking, or finishing options are also available to ensure the parts meet industry standards and customer specifications. These processes provide versatility and add value to the final product.