Product Description

Our OEM Precision Machining services deliver high-quality, custom-engineered components tailored to your exact specifications. Using advanced CNC machines and cutting-edge technology, we ensure precision, tight tolerances, and superior finishes for a wide range of materials. Whether for automotive, aerospace, medical, or industrial applications, our skilled team provides reliable solutions that meet the most demanding requirements. We specialize in both low and high-volume production runs, ensuring flexibility and cost-efficiency. From prototype development to full-scale manufacturing, we are committed to delivering exceptional parts on time and within budget. Trust our expertise to bring your designs to life with unmatched accuracy and quality.

Product parameters

| List | Details |

|---|---|

| Brand Name | OEM Precision Machining |

| Item | Custom Investment Casting |

| Material | Steel/ Brass/ Bronze/ Titanium |

| Surface treatment | Polishing, Plating, Painting, Power Coating |

| Process | Silica Sol, Water Glass, Plaster |

| Sample | Free samples can be sent after paying the mold fee |

| Drawing format | 2D: PDF, DWG, DXF 3D: STEP, STP, IGS |

| Payment | T/T, PayPal, Alipay, L/C, Western Union |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

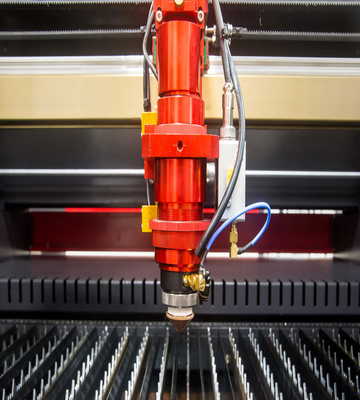

Laser Cutting

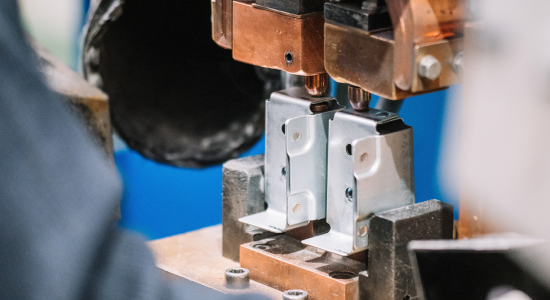

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Our Quality Control (QC) process for OEM Precision Machining ensures the highest standards of accuracy and reliability. Every part undergoes rigorous inspection using advanced tools such as CMM (Coordinate Measuring Machines), micrometers, and visual checks to verify dimensional precision and surface quality. We perform in-process monitoring to detect any deviations and ensure consistent results. Material testing, including hardness and composition analysis, guarantees the durability of each component. Our team adheres to strict industry standards and customer specifications, ensuring each part meets or exceeds expectations. Only parts passing our thorough QC checks are approved for delivery, ensuring customer satisfaction.

Processing capability

Our OEM Precision Machining capabilities are designed to deliver high-quality, custom parts with exceptional accuracy for various industries. Using state-of-the-art CNC machines, including multi-axis mills, lathes, and turning centers, we can produce components with tight tolerances and intricate geometries. We handle a broad range of materials such as aluminum, stainless steel, titanium, and plastics, offering versatility for any project.

Our machining processes include milling, turning, grinding, and drilling, allowing us to create parts with complex features and exceptional surface finishes. Whether for prototyping or large-scale production, we offer flexibility to meet specific volume requirements. We ensure precise machining for high-demand applications in automotive, aerospace, medical, and industrial sectors.

Additional processes

With advanced CAD/CAM software and skilled technicians, we optimize tool paths and minimize cycle times while ensuring high-quality output. Our precision machining services cater to both small and large components, with capabilities to handle various sizes and configurations. We also offer additional services like surface treatments, threading, and assembly, ensuring comprehensive solutions for all your OEM needs.