Product Description

High-precision custom CNC components made from aluminum and stainless steel, tailored to your specifications for superior durability, performance, and exact fit in any application. Our expert machining services ensure that each part meets stringent quality standards, providing exceptional reliability and functionality.

Product parameters

| Product Material | 1) AL1060, AL6061, AL6061, AL5052 |

| 2) Steel, mild steel, SPCC | |

| 3) SS201, SS303, SS304, SS316, SS316L | |

| 4) SPTE, galvanized sheet | |

| 5) Brass, copper | |

| 6) ABS, PP, PE, PC, POM | |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, textured |

| Size | 1) According to customers' drawings |

| 2) According to customers' samples | |

| Drawing Format | step, dwg, igs, pdf |

| Payment Term | T/T, L/C, Trade Assurance |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

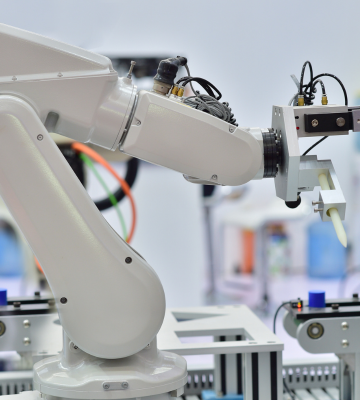

Robotic Arms

Reason: CNC machined aluminum and stainless steel components are used in robotic arms for their strength, lightweight properties, and precision. These materials enable the production of complex, durable parts that allow for smooth and accurate movements in industrial applications.

Industrial Machinery Components

Reason: Custom CNC aluminum and stainless steel parts are ideal for industrial machinery, such as gears, shafts, and brackets. These materials offer excellent strength, corrosion resistance, and durability, ensuring reliable performance and long-term use in heavy-duty equipment.

Sports Equipment and Bicycles

Reason: Aluminum and stainless steel CNC components are commonly used in sports equipment and bicycles, such as bicycle frames or fitness machine parts. Their lightweight, high strength, and weather resistance make them perfect for applications requiring durability and top performance.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control for Custom Aluminum & Stainless Steel CNC Components involves rigorous inspections and testing to ensure every part meets precise specifications and industry standards. Each component undergoes dimensional accuracy checks using advanced measuring equipment, such as coordinate measuring machines (CMM), to verify tolerances. Surface finish and material integrity are inspected to ensure they meet design requirements and are free from defects.

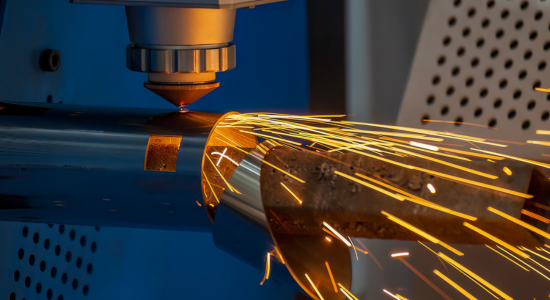

Processing capability

The processing capability of Custom Aluminum & Stainless Steel CNC Components includes high-precision machining, turning, milling, and drilling to create complex and intricate designs. Advanced CNC machines can handle tight tolerances and produce parts with exceptional dimensional accuracy and surface finish. These capabilities extend to various sizes and shapes, from small intricate pieces to larger structural components.

Additional processes

Additional processes for Custom Aluminum & Stainless Steel CNC Components include surface treatments such as anodizing, polishing, sandblasting, and powder coating to enhance appearance, durability, and corrosion resistance. Heat treatment can be applied to improve material strength and hardness, while deburring ensures smooth edges and eliminates imperfections. Threading, tapping, and engraving are also available for functional or branding purposes.