Product Description

A well-crafted and high-quality end product is the outcome of a meticulously designed and manufactured progressive die, and at CAM Resources, that's our commitment.

Our team of design engineers and technicians possesses extensive knowledge in metal stamping and die-casting applications for various industries. Leveraging the latest machining technologies enables us to take on the finest details effortlessly.

Product parameters

| Material | Steel or Carbide |

| Accuracy | Subject to the drawing details. |

| Delivery time | 14 days |

| Urgent delivery | 7 days |

| Color | Silver |

| Size | Customzied |

Custom Process

1.Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Process Type

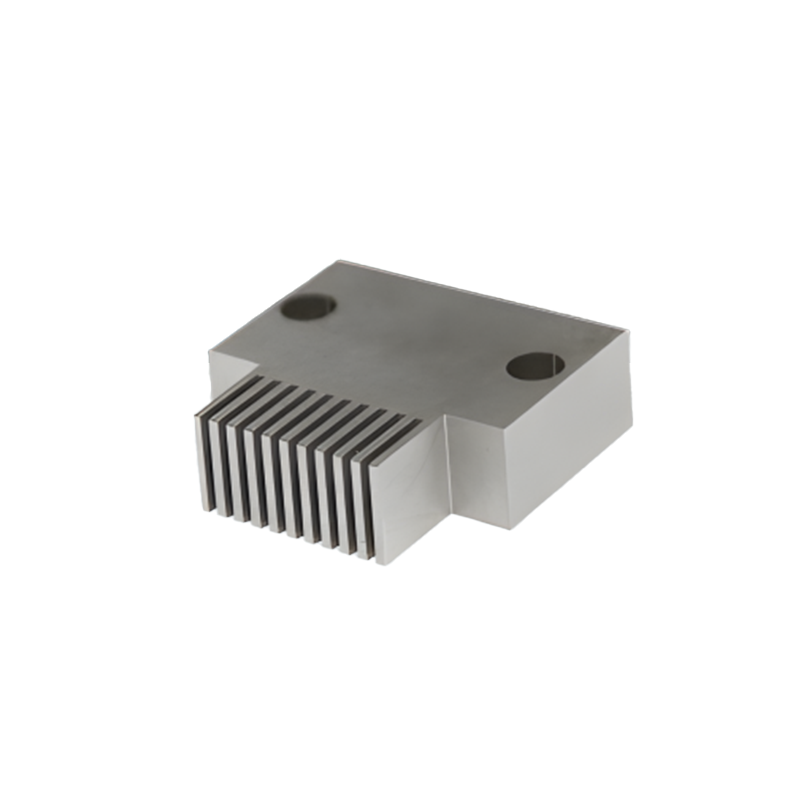

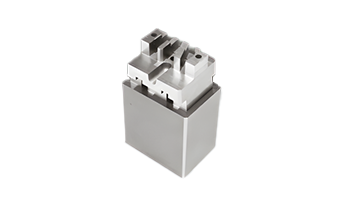

MOLD COMPONENTS

DIE COMPONENTS

JIGS&FIXTURES

Material

Carbide material E20

Carbide material KD20

STEEL SKD11

STEEL SKH54

Quality Control

Coordinates Measuring Machine(CMM)

Maker: Accretech

Model No: Mju NEX 5/8/4C6

XN/Zaxb:510*760*410

Accuracy E=+/-<0.002+4.0L/1000)

L: Meas Length, unit: mm

Measuring Microscope

Maker: Sinowan X/Yaxis:300x200

Modei No: MS3020 Accuracy:+/-0.002

Measuring Microscope

Maker: Sinowan X/Yaxis:300x200

Modei No: MS3020 Accuracy:+/-0.002

Hardness Tester

Maker: Mikrometry

Model No:DoHR150A

Processing capability

EDM machines demonstrate excellent processing capabilities, with an accuracy of +/-0.005, a high level of precision that provides a solid guarantee for precision manufacturing. In the field of complex mold processing, whether it is a fine cavity or a high-precision electrode, it can accurately carve to ensure that the dimensional deviation is controlled within a very small range and perfectly restore the design details. For tiny parts, it can achieve fine processing with extremely high stability to meet stringent process requirements. Its advanced discharge control system, combined with a precise mechanical structure, makes the processed surface finish outstanding and reduces subsequent processing steps.

The wire-cut EDM machine can achieve an accuracy of +/-0.001, and has excellent processing performance. In mold manufacturing, it can accurately cut complex contours and form millimeter-level fine structures in one go to ensure mold accuracy. When facing precision mechanical parts such as gears and watch parts, it can be finely processed with extremely small errors to ensure precise assembly. In the field of electronic manufacturing, it can accurately partition circuit boards. With advanced algorithms and high-precision transmission, it can stably and efficiently complete precision processing whether it is single-piece customization or mass production.

Software capabilities

Solidworks 2019 software to create 3D drawings and electrode designs

Solidcam software can program milling machines.

Mastercam software can program for wire cutting

This grinding machine has an accuracy of +/-0.001 and has extraordinary processing capabilities. For precision bearings, it can finely grind the raceways to control the surface roughness to an extremely low level, ensuring smooth rotation and lasting precision. After grinding the metal mold, the cavity wall is flat and smooth, and the size fit is extremely high. Relying on high-precision grinding discs and intelligent pressure control systems, it can calmly and efficiently complete precision processing tasks from single-piece trial production to batch grinding.

The CNC milling machine has an accuracy of +/-0.005, showing excellent performance. For precision machining, it mills high-precision gear teeth with perfect tooth shape and accurate transmission. When processing electronic product housings, it mills various shapes with smooth edges. With advanced CNC systems and high-rigidity spindles, it can calmly and efficiently complete milling tasks, whether it is single-piece customization or mass production, to meet diverse precision needs.