Product Description

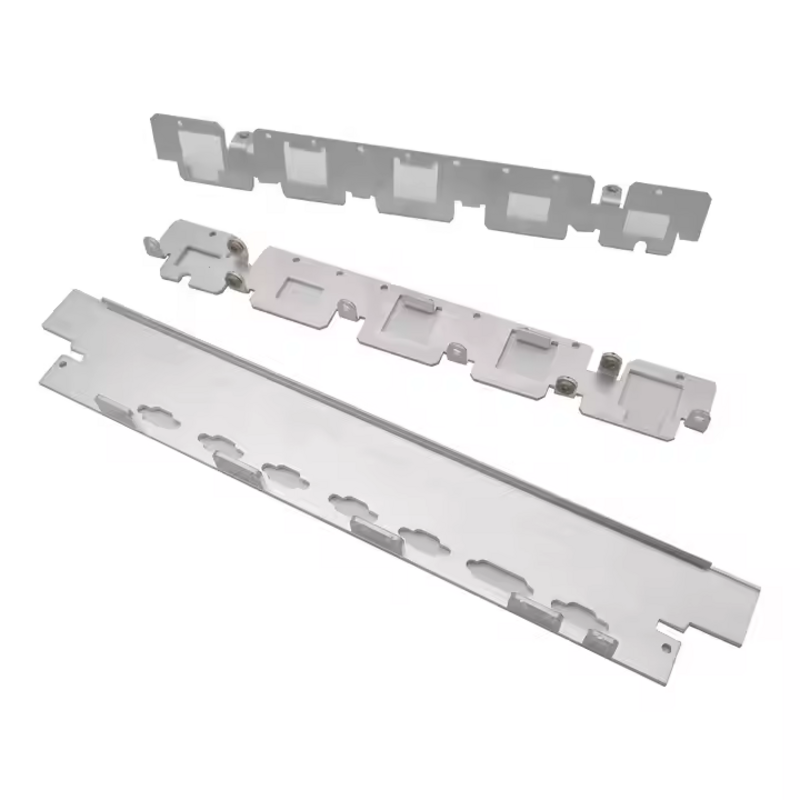

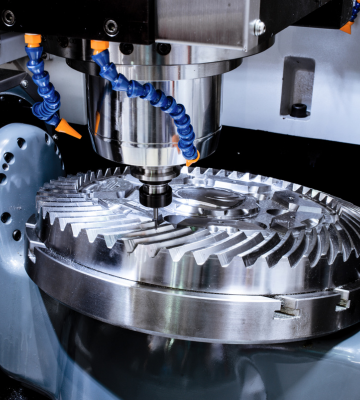

CNC – 5-Axis Machining provides high precision for processing complex shapes and specialized parts. It is suitable for materials such as 7075/6061-T6 aluminum, offering superior strength, durability, and surface quality. This technology is ideal for applications in the new energy, aerospace, and automotive industries.

Product parameters

| Stainless Steel | SUS304, SUS303, SS316L, SS316, 17-4PH, etc. |

| Materials | Brass: H60, H62, H63, H65, H68, 260, C360, H59, H70, Bronze, Copper |

| Steel: 1045, 4140, 1214L, 1215, SCM440, 40CrMo, etc. | |

| Titanium: Grade F1-F5 | |

| Plastics: PVC, PU, Acrylic, ABS, PTFE, PEEK, Acetal, POM, PA, Nylon, PC, PMMA, etc. | |

| Tolerance | +0.01mmto +0.005mm |

| Surface Treatment | Silk Screen, PVD Plating, Brushing, Passivation, Anodized, Bead Blasted, Electrophoresis, Painting, Zinc/Nickel/Chrome/Titanium Plating, PowderCoated, Electro Polishing, Knurl, Laser/Etch Engrave, etc. |

| Surface Roughness | Min Ra 0.1-3.2 |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

CNC Milling Machine

Used for precise cutting and shaping of materials such as metals and plastics

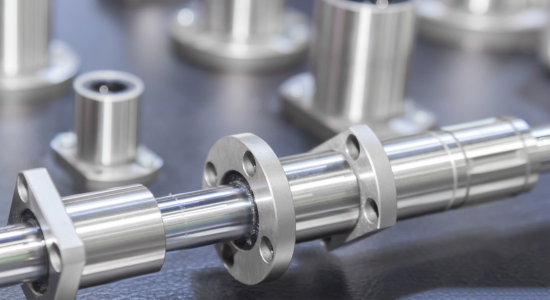

Lathe

For turning and cutting cylindrical or round parts.

Wood Cutting Machine

Used in the woodworking industry to cut and shape wood for furniture and other products

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

CNC – 5-Axis Machining emphasizes strict quality control at every stage of the process to ensure the accuracy and durability of the final product. With tolerances up to ±0.005mm, each component is inspected using advanced measuring tools such as CMM (Coordinate Measuring Machine) and other digital inspection tools

Processing capability

CNC – 5-Axis Machining offers advanced processing capabilities to produce components with complex geometries and high precision. It is capable of processing materials such as aluminum, stainless steel, titanium, copper, plastics, and more, with tolerances as low as ±0.005mm. This technology is suitable for a variety of applications such as machining prototype parts, industrial components, and specialty products that require a high-quality finish. With surface finishes such as anodizing, PVD plating, and bead blasting, this process guarantees aesthetic and long-lasting results.

Additional processes

CNC – 5-Axis Machining offers a variety of additional processes to enhance the quality and functionality of the final product. Processes such as anodizing, PVD plating, and electro-polishing are used to increase corrosion resistance and provide superior surface appearance. To meet more specific design requirements, laser engraving and scribing processes can be used to add markings or patterns to the surface.