Product Description

Our high-precision precision machined parts are a perfect combination of exquisite craftsmanship and advanced technology. From the rigorous selection of raw materials to the micron-level precision control during the processing, every step shows professionalism and persistence. Whether it is a complex internal structure or a fine external contour, it can be accurately presented to ensure that the parts can run stably in various high-end equipment, providing solid, reliable and precise core component support for your industrial manufacturing needs.

Product parameters

| Main Materials | Aluminum, copper, carbon steel, stainless steel, steel alloy, aluminum alloy, etc. |

| Surface treatment | Anodizing, coating, galvanizing, thermal spraying, polishing, plating, etc. |

| Production Equipment | 1. CNC machining center |

| 2.CNC Lathe | |

| 3.CNC Milling Machine | |

| 4.Precision Cutting Machine | |

| Quality Control | 1. Incoming materials will be carefully inspected before production. |

| 2. Strict processing quality control |

Custom Process

1. Demand communication

2. Solution design

3. Quotation

4. Contract signing

5. Prepayment

6. Production delivery

7. Inspection and acceptance

8. Final payment settlement

Process Type

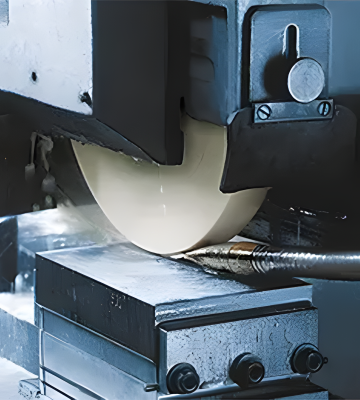

CNC Milling Machine

AMG Vietnam is known for its advanced CNC milling capabilities. We CNC milling machines are equipped with precision technology, allowing for high-quality production of complex parts. These machines are widely used in various industries, including automotive, aerospace, and electronics.

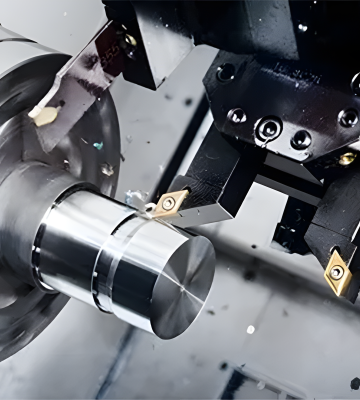

CNC Turning Machining

AMG specializes in high-precision CNC turning machining services. Utilizing advanced CNC technology, we produce intricate components with excellent accuracy and surface finish. AMG is committed to delivering reliable and cost-effective manufacturing solutions for various industries.

Grinding Machine

AMG Vietnam offers advanced grinding machine services for precision machining needs. We capabilities include:Precision Grinding. Variety of Processes

AMG Vietnam is dedicated to delivering high-quality grinding solutions tailored to client specifications across various industries.

Material

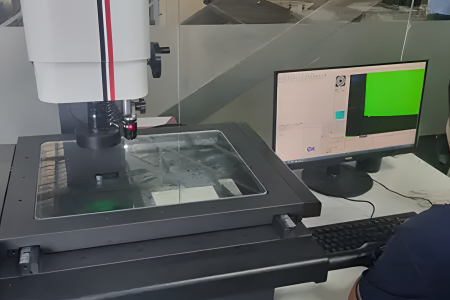

Quality Control

Quality standards are important guidelines to ensure that products meet specific requirements for safety, performance, and reliability. For companies like AMG Vietnam that export mechanical products abroad, adhering to strict quality standards is essential to maintaining customer trust and ensuring that products meet the high expectations of industries such as aerospace, automotive, medical devices, and electronics. These standards not only help ensure that products are manufactured correctly, but also help meet international regulations and certifications.

Processing capability

Precision CNC machining is an advanced automated machining method that uses a computer digital control system to precisely control the movement and operation of machine tools. Through pre-written program codes, the tool path, cutting speed, feed rate and other parameters are precisely controlled to perform milling, drilling, boring, tapping and other machining operations on various materials such as metals and plastics. It can efficiently and accurately manufacture parts with complex shapes and extremely small tolerances. It is widely used in many high-end manufacturing fields such as aerospace, automobiles, electronics, and medical equipment, and has effectively promoted the precision development of modern industry.

Additional processes

Spraying is one of the important means of surface treatment for high-precision precision machining parts. It uses a spray gun to atomize the paint and evenly cover the surface of the part to form a protective film. Through advanced technologies such as electrostatic adsorption, the paint is tightly attached to enhance the uniformity and adhesion of the coating. It can not only effectively prevent parts from rusting and corrosion, but also give parts different colors and gloss according to needs, improve their beauty and recognition. It is widely used in various precision machinery parts to meet diverse performance and appearance requirements.