Product Description

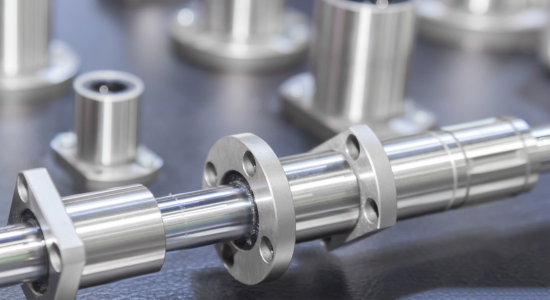

Stainless steel CNC machining services offering high precision and superior craftsmanship to perfectly meet industrial needs. Our advanced technology ensures exceptional accuracy in milling, turning, and drilling processes, delivering reliable and durable components.

Product parameters

| Type | Stainless Steel or Iron CNC Milling Parts |

| Material | Steel Alloy: 1020, AISI5135 |

| Surface treatment | Oxide, Electric Polishing, Plating, Powder Coating, Painting |

| Feature | Custom service |

| Sample | Samples Offered |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Die casting

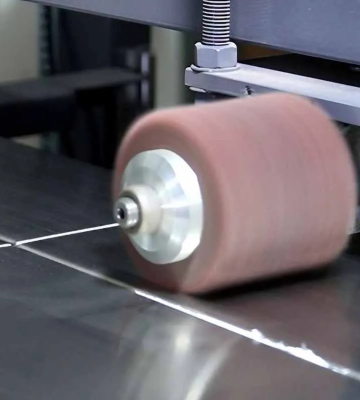

Polishing

CNC machining

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for precision CNC stainless steel machining focuses on maintaining strict tolerances, ensuring material integrity, and delivering flawless finishes. Every component undergoes comprehensive inspections using advanced measuring equipment, including coordinate measuring machines (CMMs), to verify dimensional accuracy. Surface finishes are checked for smoothness and consistency, while durability tests ensure the material meets required strength standards.

Processing capability

The processing capability of precision CNC stainless steel machining includes advanced techniques such as milling, turning, drilling, and tapping, enabling the creation of highly complex and intricate components. With the ability to achieve tight tolerances and smooth surface finishes, the process supports a wide range of applications, from prototypes to high-volume production. It accommodates various stainless steel grades and ensures consistency in dimensional accuracy and material performance.

Additional processes

Additional processes for precision CNC stainless steel machining enhance the functionality and quality of the final components. These include surface treatments such as polishing, passivation, and electroplating to improve corrosion resistance and aesthetic appeal. Heat treatment processes can be applied to enhance material hardness and durability.