Product Description

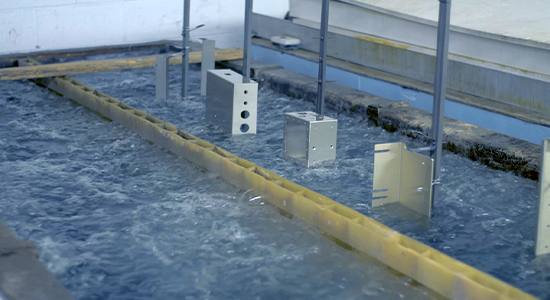

Our custom aluminum manifolds are carefully crafted using advanced CNC milling technology, ensuring high precision and excellent performance. At the same time, they are anodized to form a strong oxide film on the surface, which not only enhances corrosion resistance but also gives the product an aesthetic appearance. This customized aluminum manifold can perfectly meet your specific needs both in terms of structure and durability.

Product parameters

| Specification | According to your requirements(design drawing or sample) |

| Material | Aluminum,Stainless steel,Brass,Copper,Carbon Steel, Beryllium Copper,Titanium Alloy,Plastic, etc. |

| Processing Method | CNC Turning, CNC Milling,Die Casting,Dilling Thread,etc |

| QC Control | 100% Inspection before Shipment |

| Packaging | Regular: Paper, Foam, PE bag, Carton,Pallet; Other: According to customers' requirements |

Custom Process

1. Demand communication

2. Solution design

3. Quotation

4. Contract signing

5. Prepayment

6. Production delivery

7. Inspection and acceptance

8. Final payment settlement

Process Type

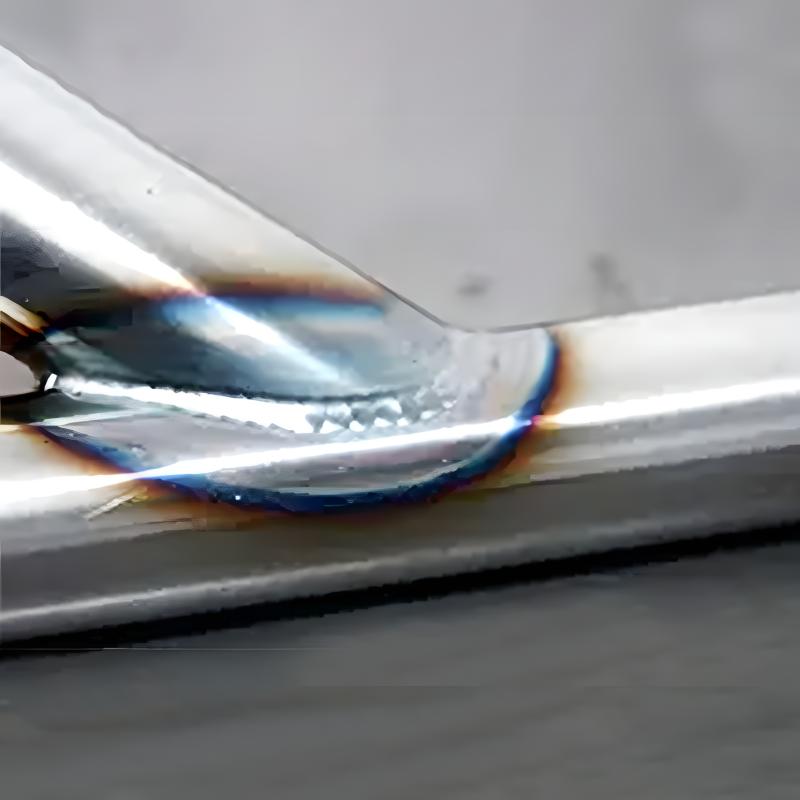

Welding process: When the manifold is composed of multiple components, welding is a critical process. For example, some large and complex industrial manifolds may first be processed into several small components, and then connected into a complete manifold by welding. To ensure that the sealing and strength of the welds meet the use standards, advanced welding technologies such as argon arc welding and laser welding are often used to ensure welding quality.

Plasma cutting (plasma arc cutting): Plasma cutting plays an important role in manifold manufacturing. It can quickly and accurately cut metal materials, whether stainless steel or aluminum alloy. Through plasma cutting, parts that meet the design shape of the manifold can be obtained, providing a high-quality parts foundation for subsequent welding and assembly processes, and improving overall production efficiency.

Casting process: If the manifold is manufactured by casting, such as sand casting, the corresponding sand mold will be made according to the designed model, and the molten metal liquid (such as aluminum alloy liquid) will be poured into the sand mold. After cooling and solidification, the blank will be taken out, and then the preliminary manifold product will be obtained through cleaning, polishing and other processes. For some manifolds with complex shapes and many irregular flow channels inside, casting is a more suitable process, which can better form the required shape.

Material

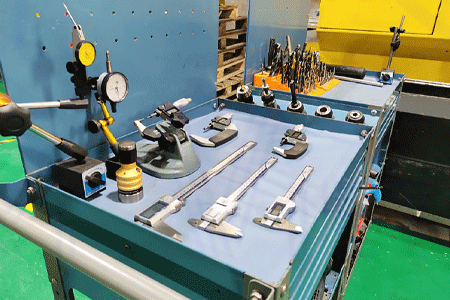

Quality Control

Quality standards are important guidelines to ensure that products meet specific requirements for safety, performance, and reliability. For companies like AMG Vietnam that export mechanical products abroad, adhering to strict quality standards is essential to maintaining customer trust and ensuring that products meet the high expectations of industries such as aerospace, automotive, medical devices, and electronics. These standards not only help ensure that products are manufactured correctly, but also help meet international regulations and certifications.

Processing capability

We have a team of staff with many years of experience in the field of mechanical processing.

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day.

Additional processes

Many manifolds need to be surface treated after manufacturing. For metal manifolds, the most common treatment is anodizing. For example, anodizing of aluminum alloy intake manifolds can improve their surface hardness, wear resistance and corrosion resistance.