Product Description

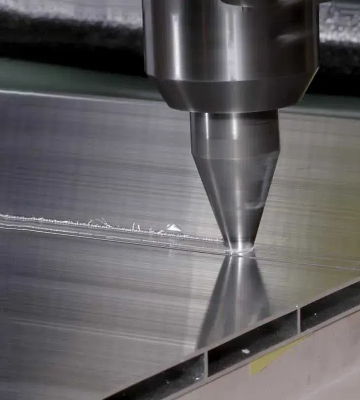

Our OEM laser cutting sheet metal products are precision-engineered for various industrial applications. Made from high-quality metal sheets, they are cut with laser technology for clean, accurate edges. These parts are customizable to meet specific design requirements, ensuring a perfect fit for each project. With fast turnaround times and excellent durability, our products provide reliable performance in demanding environments. They are ideal for sectors such as automotive, electronics, and machinery. Our advanced cutting process guarantees high precision and consistency in every piece.

Product parameters

| List | Details |

|---|---|

| Product name | Laser Cutting Processing Laser Cutting Service Sheet Metal Fabrication |

| Thickness | 0.1mm-12mm |

| Surface treatment | Electric plating,powder coated,sand blasting,lacquer |

| Testing | Salt spray |

| Certification | ISO 9001:2008, RoHS |

| Packing | Plastic Bag+carton+pallet |

| Process | Punching, stamping, bending, riveting, etc |

| Application | Construction, Automotive,Industrial, electronic, |

Custom Process

Design and Programming

Machine Setup

Welding Process Execution

Post-Welding Inspection

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

Our quality control for OEM laser cutting sheet metal ensures precise and consistent results. Each part undergoes thorough inspection for dimensional accuracy and surface finish. We use advanced measuring equipment to verify tolerances and ensure perfect cuts. Non-destructive testing is applied to check for any material defects. Our QC team performs functional tests to confirm the part's performance in real-world applications. Only products meeting the highest quality standards are approved for shipment.

Processing capability

Our OEM laser cutting sheet metal capabilities provide high precision and flexibility for various industries. We utilize advanced laser cutting machines that offer precise, clean cuts with minimal material waste. Capable of processing a wide range of metals, including stainless steel, aluminum, and carbon steel, we ensure optimal results for each material. Our machines handle varying thicknesses and sizes to accommodate custom projects, offering both small and large-scale production runs.

We also provide additional services such as deburring, edge finishing, and CNC punching for added versatility. Our team is skilled in both prototyping and mass production, ensuring quick turnaround times without compromising quality.

Additional processes

Advanced CAD/CAM software supports the efficient design and development of parts.

With consistent accuracy and high-speed processing, we guarantee high-quality output that meets exact specifications. We are equipped to deliver reliable results with both simple and complex designs. Our laser cutting services ensure clean edges and tight tolerances, meeting the highest industry standards.