Product Description

Building HBT Vietnam Precision Mechanical Joint Stock Company into a supporting industry company specializing in processing precision mechanical parts for foreign companies in Vietnam, companies abroad, large domestic companies

We are committed to bringing customers high quality products and reasonable prices, striving to satisfy 99% of customers through systems, equipment imported from Japan and a team of experienced staff in production and manufacturing

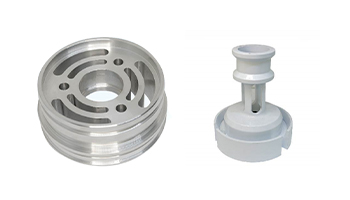

Mechanical details serving supporting industries (automotive industry, motorbike industry, electrical industry, electrical cabinets ..)

Product parameters

| Product size | Customized by samples or drawings |

| Main Materials | Aluminum, copper, carbon steel, stainless steel, steel alloy, aluminum alloy, etc. |

| Delivery time | 5-7 days |

| Production Equipment | 1. CNC machining center |

| 2.CNC Lathe | |

| 3.CNC Milling Machine | |

| 4.Precision Cutting Machine | |

| Quality Control | 1. Incoming materials will be carefully inspected before production. |

| 2. Strict processing quality control |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

Process Type

Material

Aluminum

Brass

Steel

Steeless

Processing capability

Fanuc Oi MF-driven VMC850II/P vertical machining center

Integrates high efficiency and precision. Its control system Fanuc Oi MF has excellent performance, convenient operation, and can accurately execute complex instructions. The machine tool has a stable structure and is suitable for processing various precision parts. It performs well in metal cutting, mold manufacturing and other fields, providing strong support for enterprises to improve production efficiency and ensure processing accuracy.

TSUGAMI M08J-II Lathe with Fanuc OiT controller

Opens a new chapter in precision machining. With its high-precision mechanical structure, this machine tool has demonstrated its advantages in the field of rotary body machining. Whether it is a small shaft or a complex rotary part, it can be precisely carved. The Fanuc OiT controller ensures fast command response and smooth operation. The two work together to enable precision manufacturing industries such as aviation and electronics to efficiently produce high-quality parts.

It integrates advanced mechanical technology and FANUC precision control technology, and its high-rigidity body ensures stable processing. It can complete multiple processes such as drilling, tapping, and milling in one go. It can quickly and accurately shape complex precision hardware and small molds. It is widely used in 3C and medical device manufacturing fields, helping companies improve their competitiveness.