Product Description

Metal mold production and design are at the core of our expertise, offering comprehensive services tailored to meet diverse industrial needs. We specialize in creating high-quality molds with a focus on precision, durability, and performance. Using advanced technology and modern equipment, our skilled team ensures that each mold is designed and manufactured to exact specifications, delivering reliable solutions for complex applications

Product parameters

| Service Type: | OEM/ODM customized by customer provide "Drawing" or "Sample" or "Just an Idea" |

| Material: | Steel, Stainless Steel, Aluminum, Copper, SPCC, SGCC, SECC, SPTE etc |

| Surface Treatment: | Powder Coating, Color Anodizing, etc. Multiple choices see Surface Treatment display |

| MOQ: | 1 PCS |

| Lead Time: | *Sample: within 5 days. |

| *Mass Production: within 10-20 days after receiving the deposit | |

| *Expedite Order: Service available | |

| Package: | Support customization for customer's demand. Generally package material are Plastic bags/Interleave paper + Carton + Plywood Pallet/Crate |

| Trade Terms: | EXW, FOB, CIF, CFR etc |

| Payment Terms: | *New customer: T/T 30% deposit, 70% balance after shipping out |

| *Old customer: 100% Net 30 days |

Custom Process

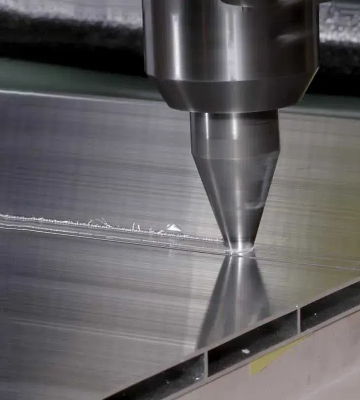

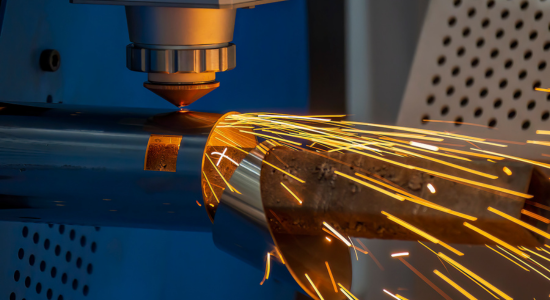

Design and Programming

Machine Setup

Welding Process Execution

Post-Welding Inspection

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Brass

Copper

Quality Control

At Precision Metal Stamping Solutions, quality control is a fundamental aspect of our operations. Every stage of the stamping process is meticulously monitored to ensure precision, consistency, and compliance with strict industry standards. We use advanced inspection equipment and techniques to verify dimensions, tolerances, and material integrity, guaranteeing that each product meets or exceeds customer specifications.

Processing capability

Precision Metal Stamping Solutions offers a broad range of processing capabilities designed to meet the most demanding requirements. We specialize in high-speed and high-precision metal stamping, producing complex components with tight tolerances and exceptional accuracy. Our advanced equipment allows us to handle various materials, including stainless steel, aluminum, and other alloys, while accommodating a wide range of thicknesses and sizes.

Additional processes

Precision Metal Stamping Solutions provides a variety of additional processes to enhance the functionality and quality of stamped components. These include deburring, polishing, and surface treatments such as plating, anodizing, and powder coating to improve durability and aesthetics. We also offer heat treatment for enhanced material strength and resilience, as well as secondary operations like tapping, drilling, and assembly to deliver ready-to-use products.

Our advanced quality assurance measures, including dimensional inspections and material testing, ensure that every piece meets exact specifications