Product Description

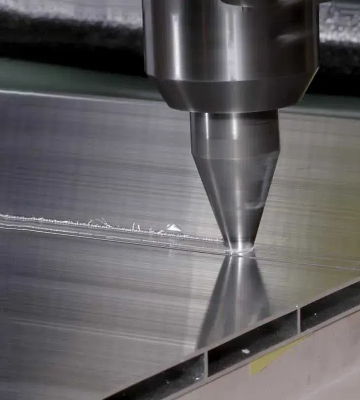

Fiber laser multi-function, small metal cutting and welding machine. Compact and easy to carry, it delivers high efficiency and precision, making it perfect for various applications. Designed for durability and accuracy, this machine is ideal for intricate metalworking, industrial fabrication, or maintenance tasks.

Product parameters

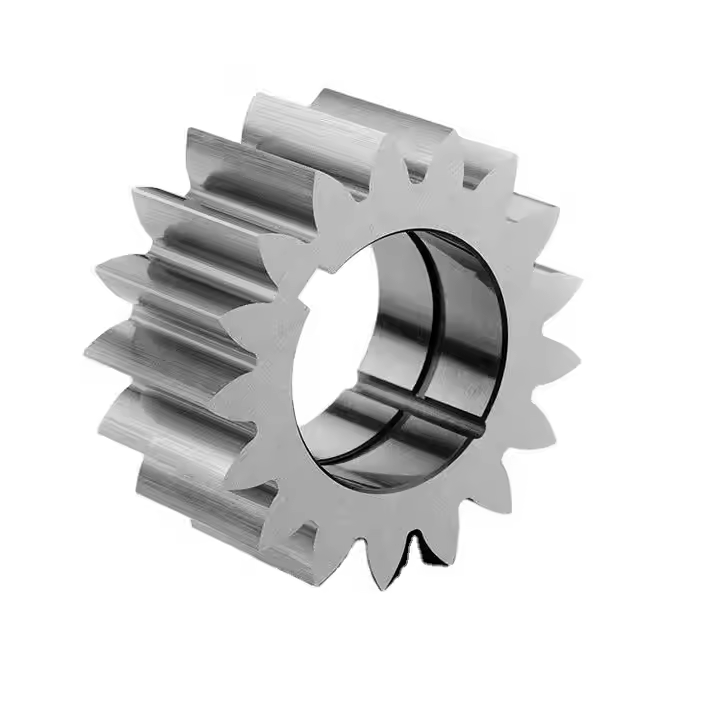

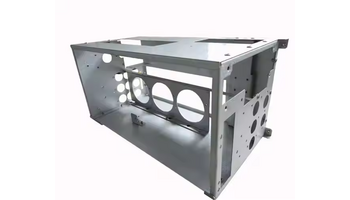

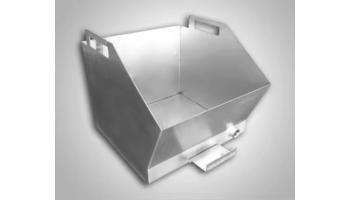

| Materials | Steel/ Aluminum/ Stainless Steel/ Plastics/ Copper/ Brass |

| Process | CNC Machining + Chamfering |

| Surface treatment | Zinc plating,Powder coated,Paint,Brushed etc |

| Product name | Sheet Metal,Fabrication,Bending,Welding |

| Service | Customized OEM |

| Color | Customized Color |

| Drawing format | 3D/CAD/DWG/PDF |

| Application | Industrial Equipment |

| Keyword | CNC Macining Parts |

Custom Process

Design and Programming

Machine Setup

Welding Process Execution

Post-Welding Inspection

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

The quality control of the Laser Multi-Tool ensures precision and reliability through rigorous testing at every production stage. Each unit undergoes thorough inspections for laser alignment, cutting and welding performance, material durability, and safety compliance. Advanced calibration techniques are applied to guarantee consistent output, while stress and endurance tests confirm its suitability for prolonged use.

Processing capability

The Laser Multi-Tool offers exceptional processing capability for both cutting and welding tasks. It efficiently handles a wide range of metals, including stainless steel, carbon steel, aluminum, and other alloys, with thicknesses suitable for small to medium-scale projects. The high-precision fiber laser ensures clean cuts with minimal thermal distortion, while the advanced welding function provides strong, seamless joints.

Additional processes

The Laser Multi-Tool offers a range of additional processes to further enhance its versatility. In addition to cutting and welding, it is capable of engraving and marking, allowing for detailed designs, logos, and serial numbers on metal surfaces. The tool can also perform surface cleaning, effectively removing rust, paint, and other contaminants, ensuring materials are prepared for further processing. With its ability to polish edges, it provides smooth, refined finishes on cut materials, reducing the need for secondary treatments.