Product Description

CNC Aluminum Gear Metal Parts 7075 are expertly manufactured with high precision, ensuring exceptional strength, lightweight properties, and long-lasting durability. Designed to meet the rigorous demands of modern industries, these components are ideal for applications requiring premium quality and superior performance.

Product parameters

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Milling, Turning |

| Micro Machining or Not | Micro Machining |

| Model Number | BP-001 |

| Brand Name | OEM |

| Product name | CNC Precision Machining |

| Accuracy | 0.001MM |

| Quality control | 100% Inspection Berore Shipment |

Custom Process

1. Product Design

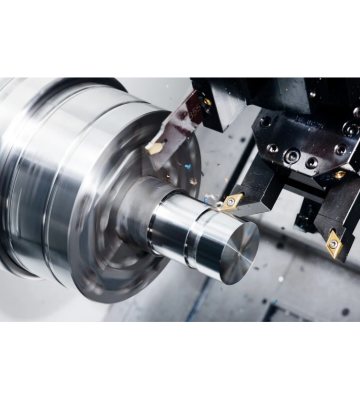

2. CNC Turning / Milling

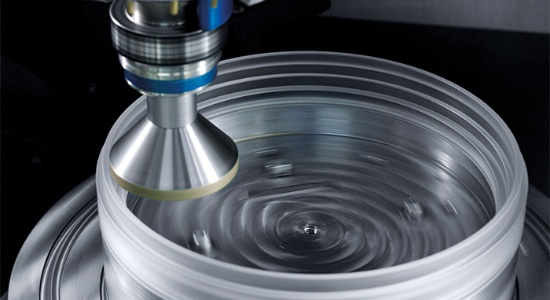

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Process Type

Turning

Lathing

Gear detection

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

The quality control process for CNC 7075 Aluminum & Stainless Steel Precision Parts involves meticulous inspections at every production stage to ensure flawless results. From raw material selection to final machining, advanced measurement tools and techniques are employed to verify dimensional accuracy, surface finish, and material integrity. Strict adherence to industry standards guarantees high precision, durability, and reliability, ensuring each part meets or exceeds customer expectations.

Processing capability

The processing capability of CNC 7075 Aluminum & Stainless Steel Precision Parts includes advanced machining techniques that deliver high precision and complex geometries. With the ability to handle intricate designs and tight tolerances, the process supports milling, turning, drilling, and threading for both aluminum and stainless steel materials. Utilizing state-of-the-art CNC machines, it achieves exceptional surface finishes and dimensional accuracy while accommodating customized specifications.

Additional processes

Additional processes for CNC 7075 Aluminum & Stainless Steel Precision Parts include a variety of finishing and enhancement techniques to ensure optimal performance and appearance. These processes may involve heat treatment to improve strength and durability, anodizing or plating for corrosion resistance, and polishing or sandblasting to achieve a refined surface finish. Specialized techniques such as deburring, engraving, and precision assembly can also be applied to meet specific functional or aesthetic requirements.