Product Description

Durable and reliable flange made of high-grade stainless steel. Rust-proof, pressure-resistant, and perfect for a variety of industrial applications. Designed to withstand harsh environments and ensure long-lasting performance, it provides a secure and leak-proof connection for pipelines and machinery.

Product parameters

| Material | Carbon steel | Q235, ASTM A105, ASTM A36, ASTM A350 LF1. LF2, LF6, S235JRG2, P245GH,P250GH, P280GH, P290GH, etc |

| 16MN, 20MN ,20# etc. | ||

| Alloy steel | ASTM A182,F1,F5,F9,F11,F22 etc. | |

| Stainless steel | ASTM A182 F304/304L, F316/316L, F316Ti, F321, F904, etc. | |

| Nickle Alloy | UNS N08020, UNS N06625, HAS C276, ETC. | |

| Flange Standard | ANSI /ASME B16.5/16.47 | Class 150 - Class 2500 |

| API 6A | Class 2000 -20000 | |

| AWWA C207 | Class B-F | |

| DIN | PN1 -PN400 | |

| BS | 6Bar 10Bar 16Bar 25Bar 40Bar | |

| EN 1092-1 | PN2.5 - PN400 | |

| GOST12820,12821, 33259-2015 | PN6- PN400 | |

| JIS B2220 | 5K - 40K | |

| AS2129 | Table A, B, E,F,H,G,K,R,S.T. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

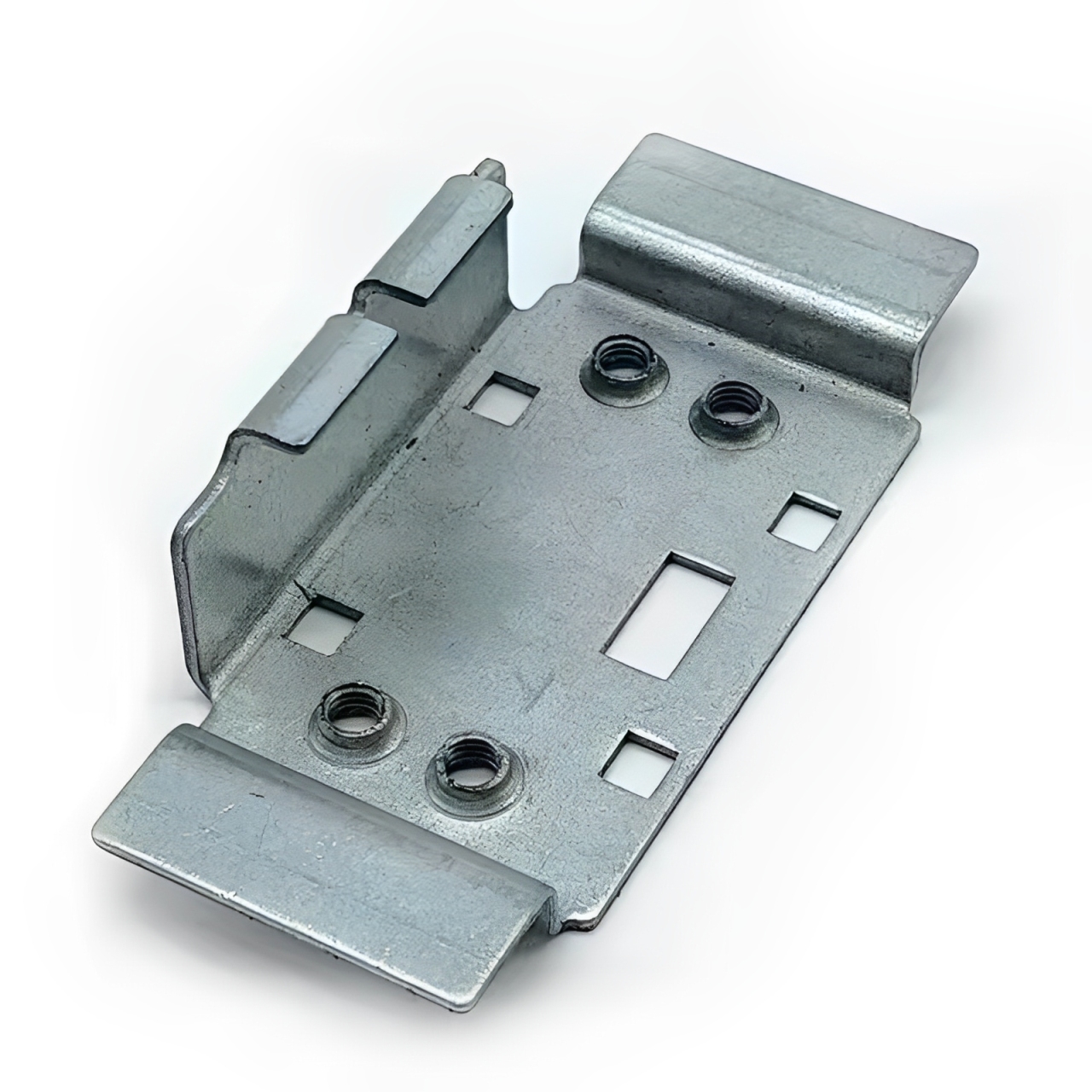

Process Type

Structural Supports

Home Appliances

Machinery Parts

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

The quality control process for corrosion-resistant products involves thorough material selection, ensuring the use of high-grade stainless steel or alloys with proven resistance to rust and wear. Each product undergoes precise machining and rigorous testing to meet industry standards for strength, durability, and performance. Advanced surface treatments, such as anodizing or coating, are applied to enhance corrosion resistance, followed by in-depth inspections for dimensional accuracy and structural integrity.

Processing capability

The processing capability of corrosion-resistant products includes advanced machining techniques, such as CNC precision cutting, drilling, and milling, to achieve high dimensional accuracy and smooth finishes. These products undergo specialized surface treatments, like anodizing, polishing, and coating, to enhance durability and resistance to rust, chemicals, and extreme environments.

Additional processes

Additional processes for corrosion-resistant products include heat treatment to enhance material strength and toughness, as well as shot blasting or sandblasting to improve surface texture and adhesion for coatings. Surface finishing techniques, such as electroplating, anodizing, or passivation, are applied to maximize corrosion resistance and aesthetic appeal. Quality assurance measures, including ultrasonic testing, pressure testing, and non-destructive evaluation, ensure product reliability.